We offer a wide range of plastic electronic enclosures for general use. Here, you’ll discover popular plastic enclosure box products in a huge array of sizes and styles. Many have special features that your application needs, such as DIN rail mounting, fiber optic splice trays, and terminal blocks.

- Small desktop plastic enclosures

- Plastic instrument case with handle

- USB enclosure

- Power plug enclosure

- DIN rail mountable enclosures

- Potting boxes

For the plastic project boxes, we offer a wide variety of ABS material thicknesses as well as any different size enclosures. Materials such as 3mm, 4mm, and 6mm– in an array of colors and we have the capability to custom color match to specific needs. Our plastic housings usually come in black, white, light grey, dark grey or any other color you want.we offer a multitude of different styles of plastic enclosures. All of these product examples are custom made for specifc customer use.

Specification

- Waterproof: IP68

- Material: ABS for box body, Polycarbonate for lid

- Environment Temperature: ABS (-45℃~85℃), Polycarbonate (-60~120℃)

- Weight: 243g

Our Service Including:

- Prototype: 3D printing, CNC, Laser cutting etc.

- Product material: ABS,PP, Nylon,PC or any other material as you need.

- Drawing: format Step., igs., x_t, dwg, pdf, stl(for 3D print)etc.

- Surface: As Custom’s Requst,heat treatment.polishing, texture,coating,etc.

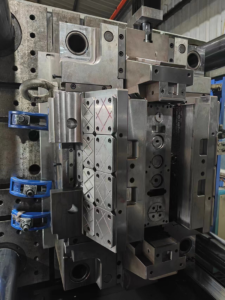

- Service:ODM,OEM,Design based on your idea or Make mold and produce based on your drawing.

- Type of enterprise: Professional manufacturer of injection molds andplastic parts.

Why Choose Us to Custom Plastic Enclosure?

- Design and Development: Our team has extensive engineering and design experience to assist you at every stage from concept to the final product. We will work with you to ensure your battery case meets all specifications and requirements.

- Material Selection: We offer a variety of plastic materials to meet different application requirements, including high-temperature resistance, chemical resistance, impact resistance, and more. We will select the most suitable material for your project based on your requirements.

- Custom Manufacturing: We can customize manufacturing according to your specifications and design requirements. Whether it’s dimensions, shapes, colors, or features, we can produce the battery enclosure to meet your needs.

- Engineering Support: Our engineering team will provide you with professional technical support, helping you resolve any potential issues and ensuring your product complies with industry standards and regulations.

- Assembly and Testing: We offer one-stop assembly and testing services to ensure your battery case meets requirements and can be immediately put into use. We can also provide services such as battery installation and wiring connections.

- Quality Control: We strictly adhere to quality control standards to ensure each product maintains consistent high quality. We perform comprehensive quality checks and testing to ensure product reliability and performance.

- Packaging and Logistics: We provide packaging and logistics solutions to ensure your products are safely transported to their destination and provide appropriate packaging materials when needed.

- After-Sales Service: Our customer support team is available to assist with any after-sales issues or requirements.