Two Shot Molding Bathroom Liquid Silicone Components Manufacturer

Product Details

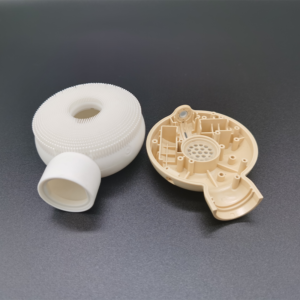

Embark on a journey of precision and innovation with our cutting-edge Dual Shot Molding expertise. Renowned in the industry as a leading Bathroom Liquid Silicone Components Manufacturer, we specialize in the art of LSR molding, an advanced technique also recognized as liquid silicone molding, liquid injection molding, 2 shot & 2k mold.

Our state-of-the-art injection molding machines are meticulously designed for the production of high-quality LSR-grade medical and FDA-grade silicone parts. We seamlessly integrate silicone with plastic, metal, and various molded materials to create a diverse range of products, including but not limited to silicon baby toothbrushes, exquisite bathroom accessories, and intricate electronic seals.

At the heart of our manufacturing process is a commitment to excellence, ensuring that each product meets the highest standards of quality and durability. Whether you are seeking precision-crafted bathroom essentials or innovative electronic components, our Dual Shot Molding capabilities elevate your expectations, delivering products that seamlessly blend functionality and aesthetics.

Choose reliability, choose innovation – choose our Dual Shot Molding solutions for your Bathroom Liquid Silicone Components needs. Elevate your product offerings with the perfect blend of technology and craftsmanship, setting a new standard for excellence in the industry.

Bathroom Accessories And Overmolding

- Dual-Process Mastery:Overmolding is a two-step technique that seamlessly merges materials like liquid silicone (LSR) or thermoplastic elastomer (TPE) over a base component.

- Precision Assembly:The base part is strategically positioned in the injection mold, allowing the thermoforming material to encapsulate it, resulting in a flawlessly assembled product.

- Versatile Applications:Widely applied in various industries, overmolding finds its place in products such as shower heads, bathroom accessories, and more.

- Enhanced Functionality and Aesthetics:This meticulous process not only boosts product performance but also adds a layer of visual appeal, making it a go-to method for innovative design.