As a medical plastic injection mold supplier, YJC has unique solutions from medical productdevelopment to mold design, mold manufacturing, and injection molding production.

Medical Device Plastic Injection Moulding Application

1. Patient care series

2. Diagnostic equipment series

3. Drug filtration series

4. Shell and component series

5. Disposable medical supplies series

6. Surgical instrument series

7. Orthopedics product series

8. Heart product series

9. Ophthalmology treatment instrument series

10. Healthcare components and equipment series

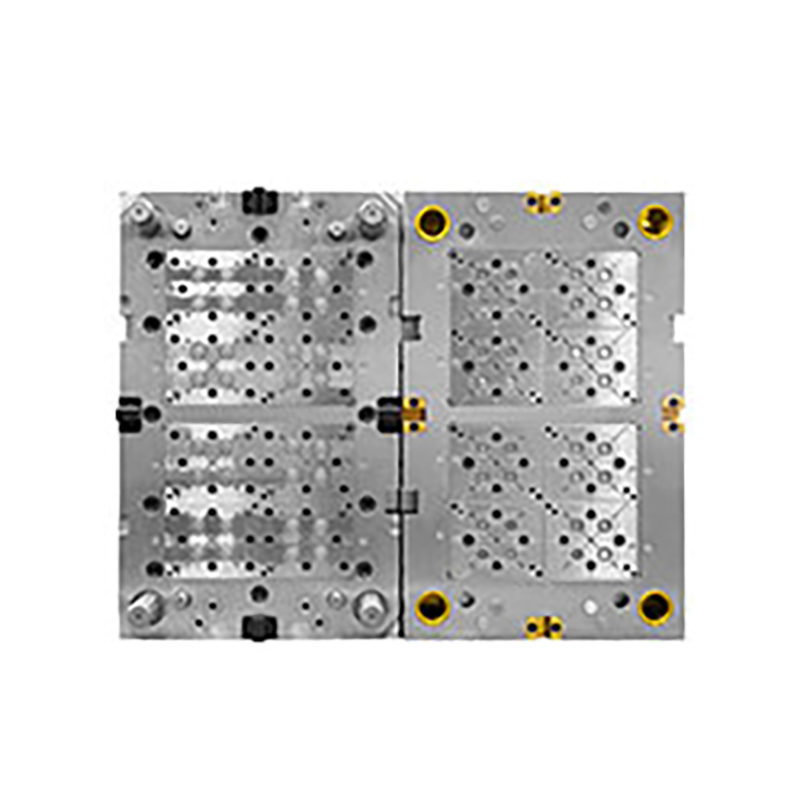

Medical Pipette Tip Mold Multi Cavity Medical Mold

Medical Injection Molds Advantages

1. Medical injection molds are versatility

2. Medical injection mold is easy to disinfect

3. Higher security

4. Injection molding medical products improve the quality of life

5. High-cost performance

6. Environmental protection

7. Medical decvice injection molding has potential for future innovation

The medical device injection moulding parts are highly specialized and precise, and have precise and detailed requirements for sterility and supervision, these requirements are much higher comparing other industries. A dust-free injection molding shop can help ensure that particulate matter, that is dust, airborne organics, or vaporized particles will not contaminate the plastics that will make up medical device injection molding components.

Our service including:

- Mold Design and Engineering Support

- Material Selection and Recommendations

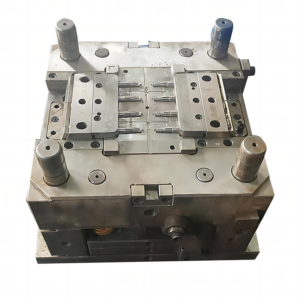

- Mold Manufacturing

- Prototype Development

- Mold Trial and Adjustment

- Rapid Delivery

- Quality Assurance

- Sustainability Practices

Capability:

- High Precision Design and Manufacturing

- Precise Reproduction of Complex Geometries

- Multi-Cavity Design for Enhanced Efficiency

- High-Temperature Resistant Materials and Manufacturing Processes

- Precision Cooling System

- Longevity and Maintenance

- Quality Control System