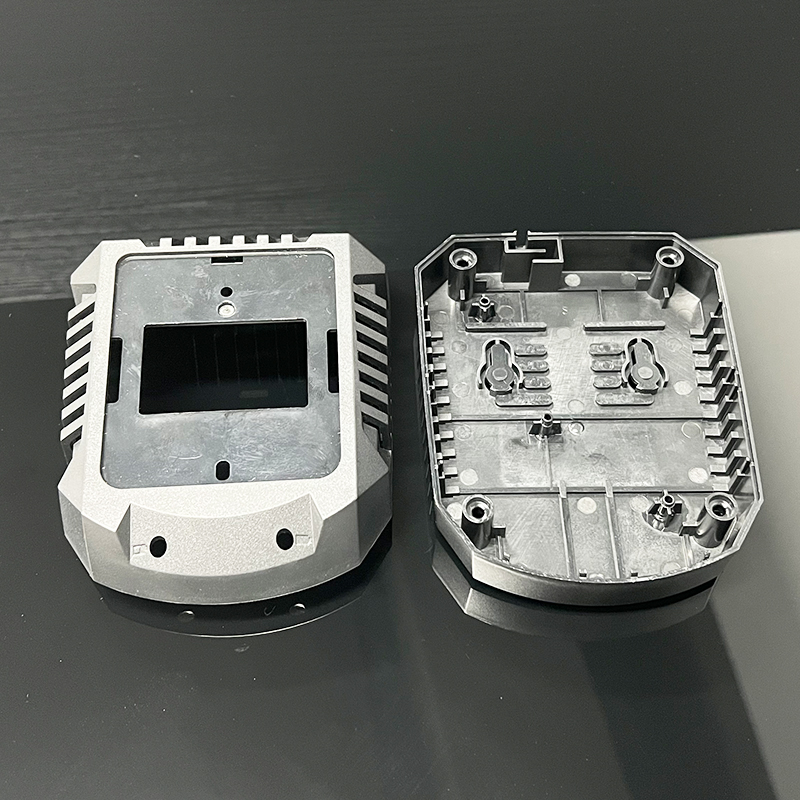

Tailored Design Plastic Battery Box Mold Injection Molding Case

Expert Injection Molding Services

Injection Molding Expertise:

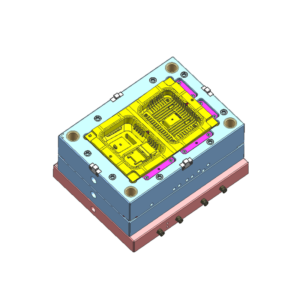

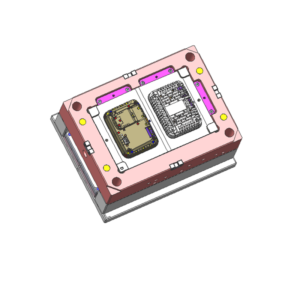

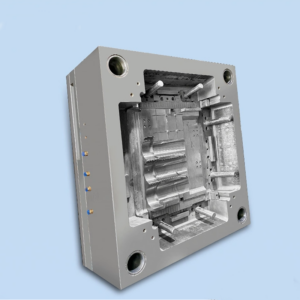

Central to the injection molding process is the injection mold – the pivotal component that shapes the entire injection molding service. This crucial mold comprises the Tooling Base, Core and Cavities, Ejection Systems, and Cooling Systems, as illustrated in the accompanying image.

Critical Factors in Injection Mold Service:

Key considerations for an effective injection molding service include material selection, meticulous mold design, and the creation of high-precision tools. Each element plays a vital role in ensuring the success of the injection molding process.

Years of Expertise:

Benefit from our extensive years of experience as we deliver high-quality injection molds and injection molding services. Our proficiency in material selection, mold design, and precision tooling sets us apart, ensuring top-notch results for our clients.

Our Distinctive Advantages:

- Seasoned Professional Team:

Benefit from our 15+ years of expertise, where our dedicated team specializes in Automotive, Medical, and Electric Mold & Products.

- Cutting-Edge Equipment:

Employing world-class processing and quality control equipment from renowned brands such as AgieCharmilles, Mitsubishi, Röders, MAKINO, Serein Croma-C, and GOM ATOM ensures precision and reliability.

- Medical Clean Room Facilities:

Our 100k-grade clean room for medical molding products and a 10k-grade laboratory guarantee impeccable quality, positioning you to secure orders and bids in the medical sector.

- Internationally Recognized Certifications:

Hold confidence in our operations with certifications including ISO 9001 and IATF 16949, attesting to our commitment to quality standards.

- Unmatched Precision:

Standard precision at 0.02mm is guaranteed, with the ability to produce even higher precision based on specific requirements.

- End-to-End Manufacturing:

Experience a seamless process from mold design to production and molding of products, saving you time and costs while maintaining control over quality and schedules.

Choose us for a holistic approach to plastic battery box molding and injection molding cases, where excellence is not just a standard but a commitment.