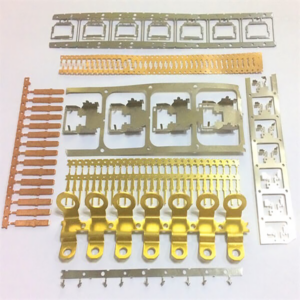

Precision-Crafted Stamping Terminal Connector Parts is designed for the electronic industry. Crafted from a variety of materials, including alloy steel, aluminum, brass, bronze, carbon steel, copper, stainless steel, and zinc, these versatile parts offer strength and durability. Surface processing options like brushing, electroplating, hot galvanizing, oxidation, pickling, polishing, powder coating, and spraying enhance both form and function. Utilizing advanced production methods such as CNC Turning, CNC Milling, CNC Lathe Metal stamping, CNC spring production, and fastener manufacturing, these parts meet stringent specifications. Trusted across diverse industries, including electronics, automotive, medical equipment, and more, our certification ensures quality and reliability.

Precision-Crafted Stamping Terminal Connector Parts is designed for the electronic industry. Crafted from a variety of materials, including alloy steel, aluminum, brass, bronze, carbon steel, copper, stainless steel, and zinc, these versatile parts offer strength and durability. Surface processing options like brushing, electroplating, hot galvanizing, oxidation, pickling, polishing, powder coating, and spraying enhance both form and function. Utilizing advanced production methods such as CNC Turning, CNC Milling, CNC Lathe Metal stamping, CNC spring production, and fastener manufacturing, these parts meet stringent specifications. Trusted across diverse industries, including electronics, automotive, medical equipment, and more, our certification ensures quality and reliability.

Specification

Material: Alloy Steel, aluminum, Brass, Bronze, carbon steel, copper, stainless steel, steel, Zinc

Surface Processing: Brushing, Electroplating, Hot galvanized, Oxidation, pickling, Polishing, powder coating, Spraying

Produce Progresses: CNC Turning, CNC Milling, CNC Lathe Metal stamping, CNC spring, Fastener etc.

Certification: ISO9001

Application: Electronic, Automotive, Electric appliance, Electrical machine, Medical, Furniture, Fitness equipment

Sample Time: 7-12 Days

Lead Time: 15-25 Days

Payment Term: T/T, L/C 30% deposits, before the ship to pay the balance end. Freight are quote under your request

Packages Term: PVC Bag + Carton + Pallet

Delivery Term: By sea/Express

Our Key Competitive Advantages

- Buyer’s Specifications Accepted: We prioritize meeting the unique requirements of our customers. We welcome and accommodate buyer’s specifications, ensuring that our products align perfectly with your needs.

- Experienced R&D Department: Our dedicated and seasoned Research and Development team consistently strives for innovation and improvement. This commitment allows us to stay at the forefront of industry advancements and deliver cutting-edge solutions.

- Large Product Line: With a diverse and extensive product line, we offer a wide range of options to cater to various industries and applications. Our comprehensive selection ensures that you find the ideal solution for your specific needs.

- OEM Capability: Our OEM capability empowers us to produce customized products with your branding and specifications. We are your trusted partner in bringing your unique ideas to life.

- Production Capacity: We boast a robust production capacity, allowing us to fulfill both small and large-scale orders efficiently. Our well-equipped facilities and streamlined processes ensure timely delivery.

Application

- Electronic: Manufacturing electronic connectors and components.

- Automotive: Producing connectors for automotive electronic systems.

- Electric appliance: Creating parts for household appliances.

- Electrical machine: Supporting electrical machinery with connectors.

- Medical: Manufacturing connectors for medical devices.

- Furniture: Used in electronic components of furniture.

- Fitness equipment: Supporting electronic features in fitness machines.