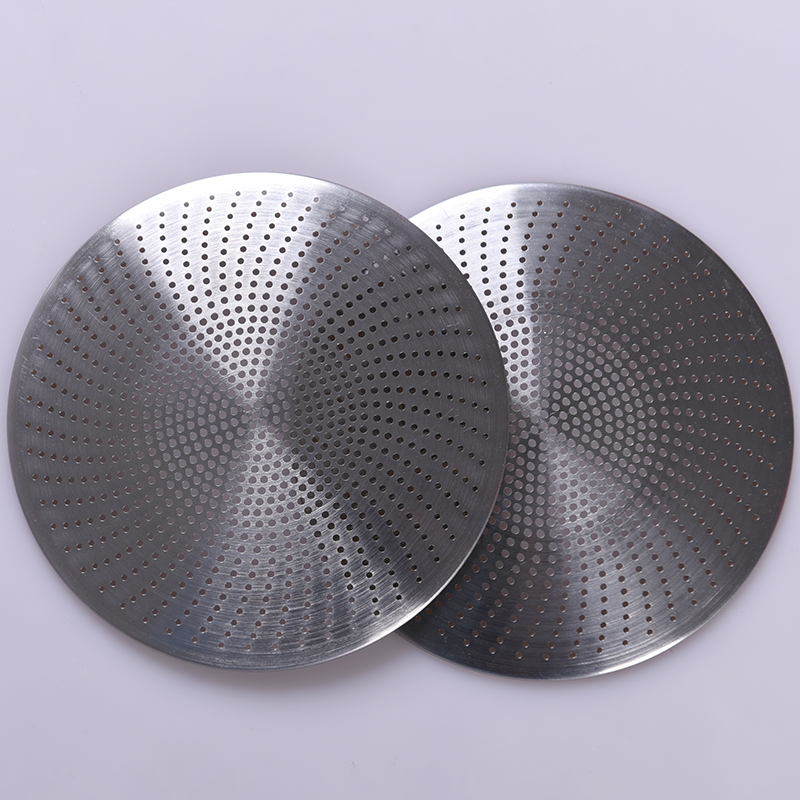

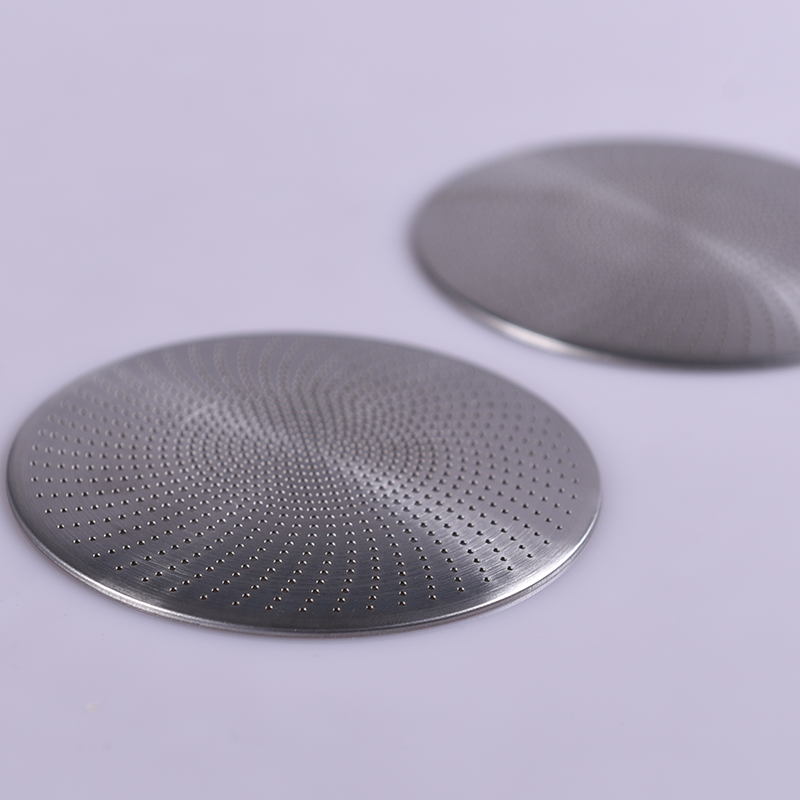

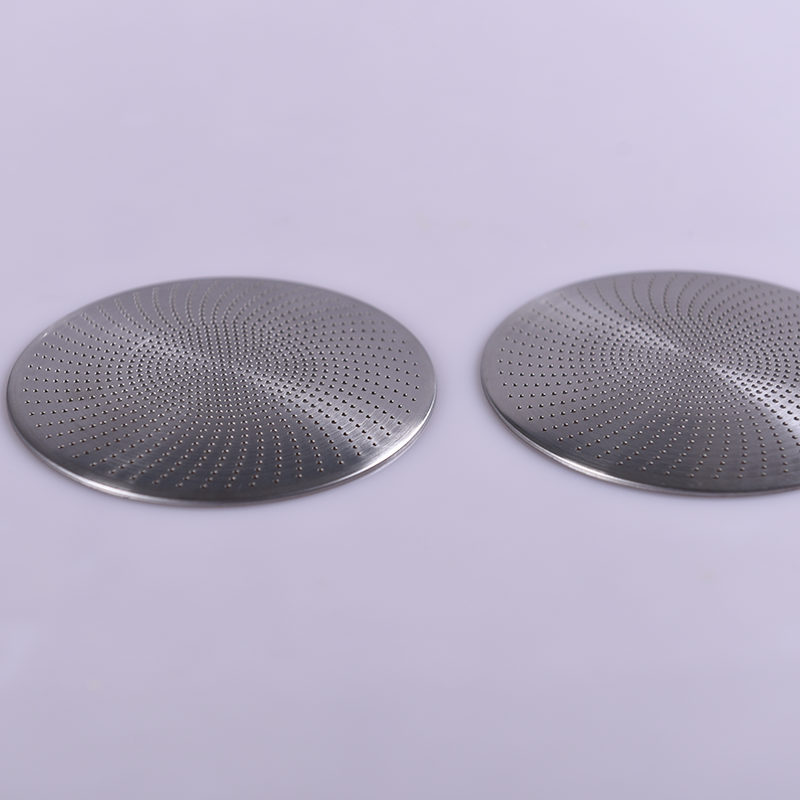

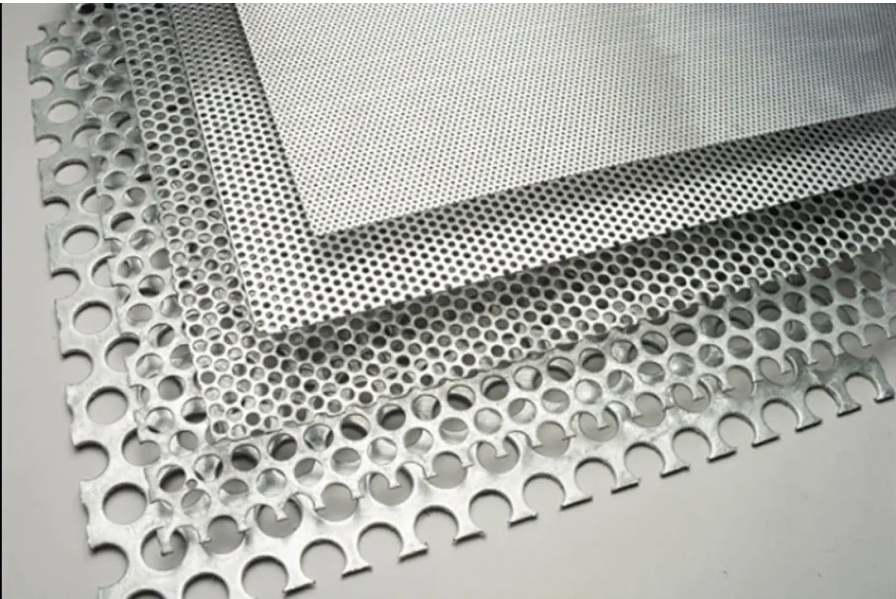

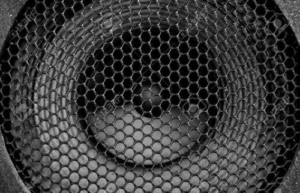

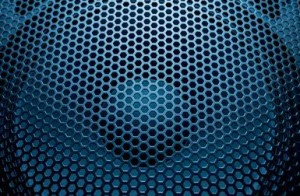

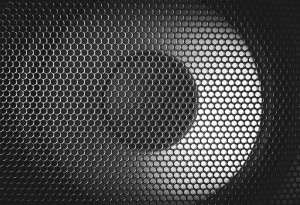

Speaker Cover Metal Stamping Parts Steel Mesh for Speaker Grill Auto Parts

Our custom metal stamping speaker cover solution encompasses design consultation, material selection, customized design, prototype production, tooling and stamping, surface finishing, quality assurance, packaging and shipping, and customer support, among other steps. This comprehensive workflow aims to efficiently manufacture speaker covers that meet or exceed customer-specific specifications and requirements in terms of functionality, aesthetics, and performance.

Material:

- Low carbon steel

- Aluminium

- stainless steel

- Brass

- Titanium

Surface treatment:

- Hot galvanizing

- Anodizing

- Powder coating

- PVC coating

- Paint, etc.

Tolerance: ± 0.005 to ±0.01mm

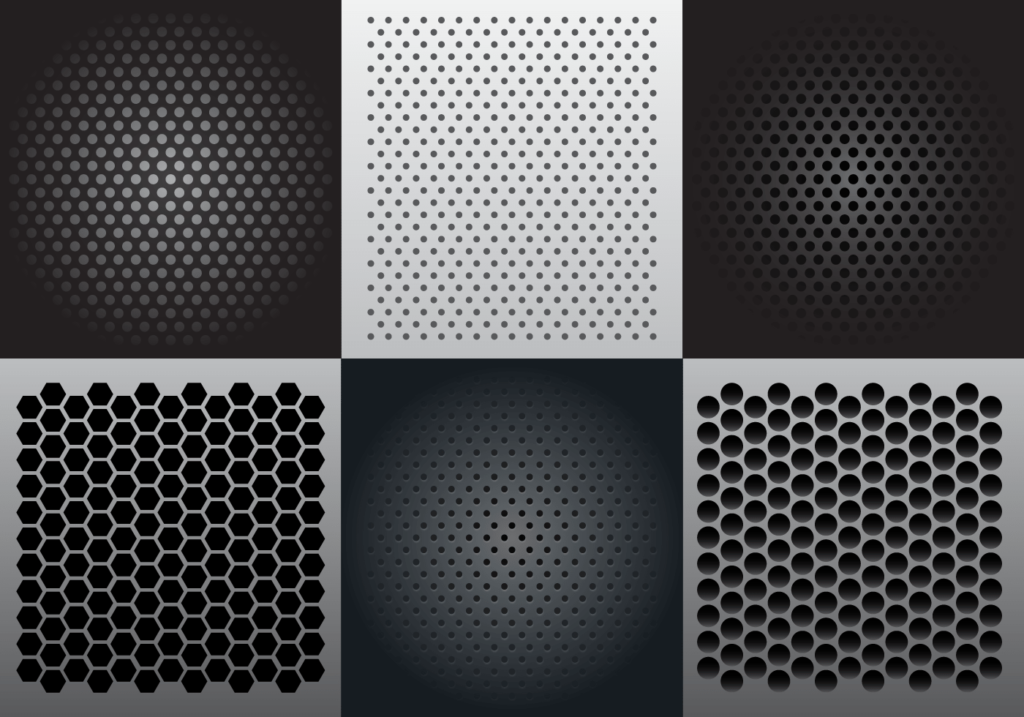

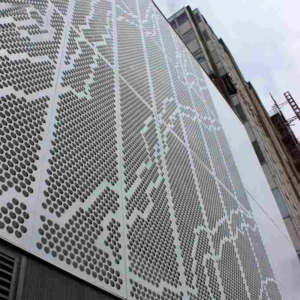

Hole Pattern Shapes

Rectangular hole, square hole, diamond hole, round hole, hexagonal hole, cross hole, triangle hole, slotted hole bore, long waist hole, the plum blossom, scales, bore hole pattern, a pentagram, irregular, the drum hole, etc.

Applications

- Speakers

- Audio Speakers

- Radio Equipment

- Equipment Ventilation Plants

- KTV Equipment, Etc.

The decorative perforated metal sheet is widely used, such as ceiling tiles and anti-slip flooring of buildings, sound-absorbing materials in the interior, infill panels of the balcony and stair railings, balusters, guardrails, architecture facade cladding, building facades systems, room divider screens, metal tables, and chairs; protective covers for mechanical equipment and speakers, fruit and food baskets, etc.

- Facade cladding

- Building decoration

- Barbecue grill

- Ceiling/curtain wall

- Furniture like chair/desk

- Security Fencing

- Micro battery mesh

- Cages for poultry

- Balustrades

- Filter screens

- Walkway & stairs

- Hand rail mesh

Our advantages

1. Fast prototyping

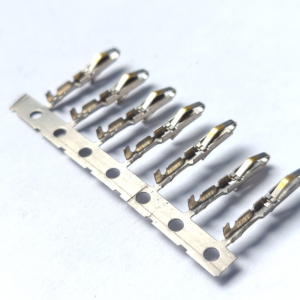

2. More than 20 years’ experience of CNC machining and stamping services

3. Small orders are accepted

4. ISO 9001/ISO 14001/ISO-TS16949 certified factory

5. Quality assurance system

6. Quick production and delivery

Our facility

1. CNC gantry milling machine, 2500x1300mm

2. CNC machining centers, drill and tap, engraving machine

3. CNC turning centers

4. Swiss lathes

5. Hydraulic stamping machines

6. Tapping machines

7. EDM wire cutting, drilling machine

8. Molded plastic injection machines

9. 3-dimensional measuring instruments, projectors, test machines