Silicone Keypad & Silicone Keyboard

Silicone Keypad & Silicone Keyboard, also knowns as Rubber Keypad & Keyboard, Silicone Rubber Buttons Silicone Keymats, which is made from elastomeric translucent silicone rubber materials by compression molding, is widely used in industrial electronic products, medical device, machinery, consumer products as a reliable silicone switches.

Silicone Keypad Design Structure:

Silicone button. button pads, silicon key & button webbing, button travel, and keypad conduction

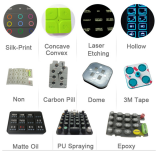

Silicone Keypad Surface Symbols & Icons:

Scren Printing, Laser Etched & Cutting for backlight & backlit legends, Embossed or Debossed Molded LegendsSpraying Coating etc.

Silicone Keypad & Button Travels:

Silicone Keypad & Button Travels:

The distance between silicone button’s conduction tand PCB conductive layersCommer Silicone Keypad Travel choose: 0.9mm – 1.2mm

Silicone Keypad Actuation Force:

Mainly choose 90grams – 180 grams for good tactile feel & sense

Surface Finishing

We offer a variety of surface treatment processes to customize the appearance and performance of silicone rubber keypads and keyboards. These processes include silk screen printing, laser engraving, oil spraying, glue dripping, and paint scraping, enabling the creation of intricate markings, textures, wear-resistant coatings, waterproof layers, and more, to meet a wide range of customer requirements for aesthetics, durability, and functionality.

What are Some Design Considerations for Rubber Keypads?

1.Actuation Force&Tactile Feedback:We meticulously determine the precise actuation force required for each key, ensuring that it strikes the ideal balance between being easy to press and providing satisfying tactile feedback upon keypress.

2.Key Travel&Ergonomics:Our designs carefully factor in the key travel distance, striking the perfect equilibrium between tactile feedback and ergonomic comfort, thereby delivering an enjoyable and efficient typing experience.

3.Durability &Environmental Adaptability:We make judicious choices in high-quality rubber materials that guarantee longevity and resilience, all while taking into account the environmental conditions in which the keypads will operate. This includes assessing temperature variations, humidity levels, and exposure to chemicals to ensure optimal performance under diverse circumstances.

Silicone Rubber Keypad Quick Quotation Requirements

1. Offer 2D & 3D Design drawings or samples

2. Keypads Legends demands.

3.Keypad’s Surface Protective Coating Demands.

4. Keypad’s Conduction Ways or Resistance Demands

5. Quantity Demands