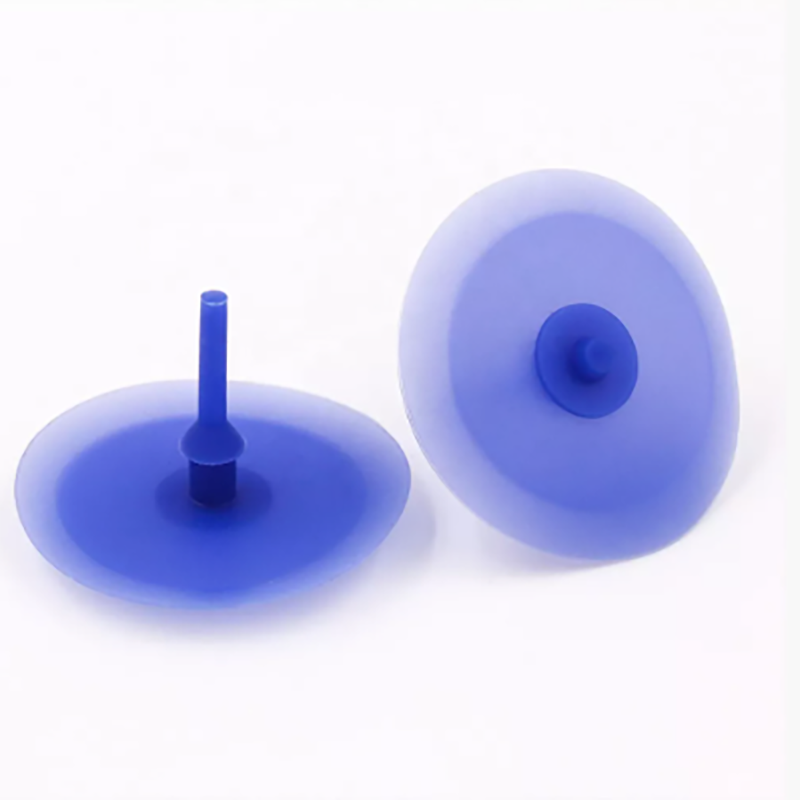

Silicone Rubber Duckbill Valve Umbrella Check Valves

Silicone Umbrella Valve Umbrella valves are elastomeric valve components that have a diaphragm shaped sealing disk or an umbrella shape ifyou like. These elastomeric components are used as sealing elements in backflow prevention devices or one-wayvalves or check valves, in vent valves or pressure relief valves and in metering valves. When mounted in a seat, theconvex diaphragi flattens out against the valve seat and absorbs a certain amount of seat irregularities and creates acertain sealing force. The umbrella valve will allow forward flow once the head pressure creates enough force to lifhe convex diaphragm from the seat and so it will allow flow at a predetermined pressure in one way and prevent backflow immediately in the opposite way.

Basic intormation

1.Common Valve Types:Duckbill Shaped Valves, Umbrella Shaped Valves, Flapper Shaped Valves and other custom made valves etc.

2.USAGE:Medical Devices Valves, Industrial Devices Valves, Aerospace Devices Valves, and 0il/GAS Devices Valves etc.

3.Medical Devices Valves:

Medical Grade Silicone Valves and Dust-Free Silicone RubberProduction Plants. Respiratory and Anesthesia Circuit Devices Valves.

4.Why Choose Us?

l) decades of experience about precision silicone rubber molding production.

2)we can offer high precise designs and sizes for silicone rubber valves to supportyour devices according to your 3 D / 2D drawings, samples, flowing parameters etc

3)We have Dust Free Silicone Rubber Compression Molding Plants and Dust- Free Dismantling Plants

4)According to customer demands, most of silicone medical parts should be produced and finished in clean room. Our dust-free plants can up to 100, 000 stage.

Umbrella Check Valve Design & Size Analysis:

1. Umbrella Shaped Dameter: bigger than one-way valve holes

2. Hook Height: same to plastic & metal panel’s height

3.Stem Diameter: same or smaller than assembly holes

4. Outside Diaphragmatic Surface: EDM process or texture surface to make sure anti dust.

5.Inside Diaphragmatic Ring Edge Surface: Polish or high-polishing for sealing function.

Umbrella Valve’s Materials Choice, Hardness Limits and Packaging DemandsUmbrella Valves Materials should choose lower compression set and high elastic elastomers (tensilestrength).

Silicone Umbrella Valve, the best made from 100% high elasticity.f contact with fuel oil or hydraulic fluid, the best choose fluoro silicone or other oil-proof synthetic rubberUmbrella Valves Hardness, generally less 55 Shore A which mainly depends on umbrella hook designsUmbrella Valve Packaging: PE Bag with air inside in aim to prevent.