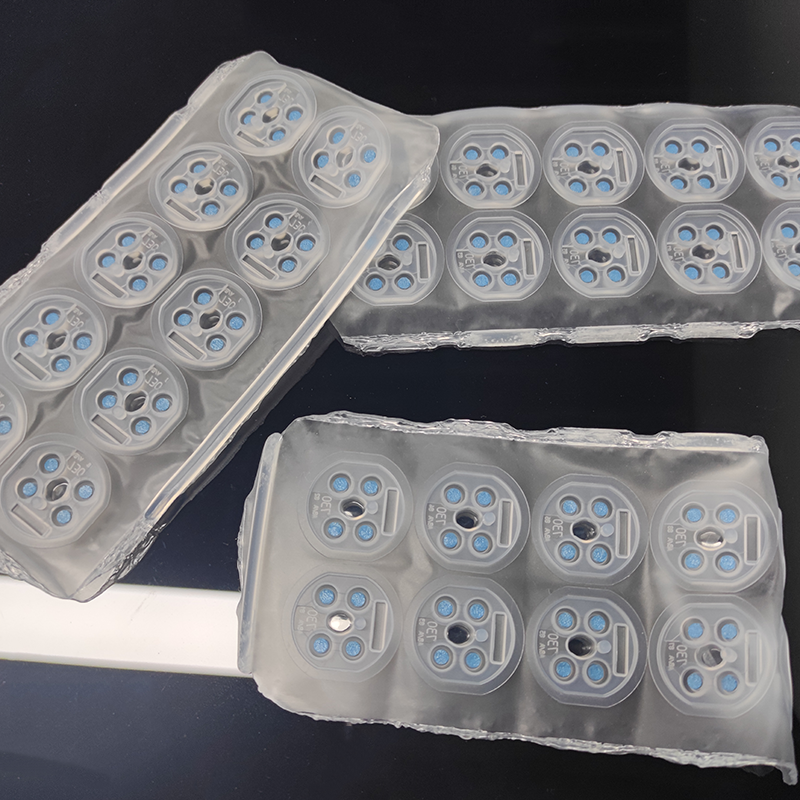

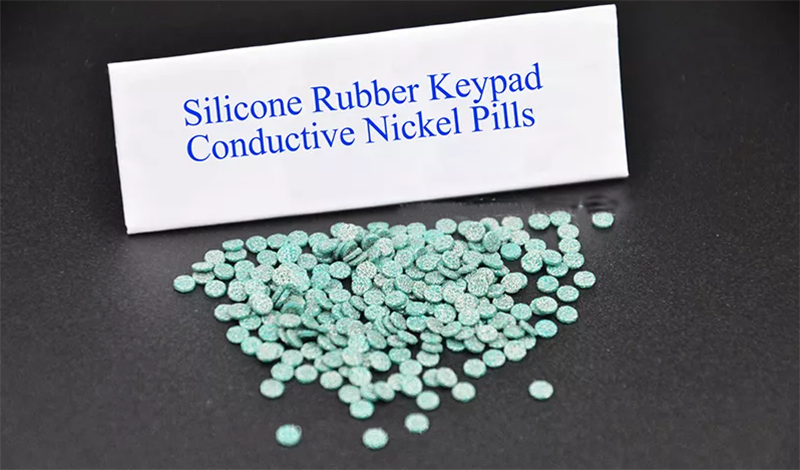

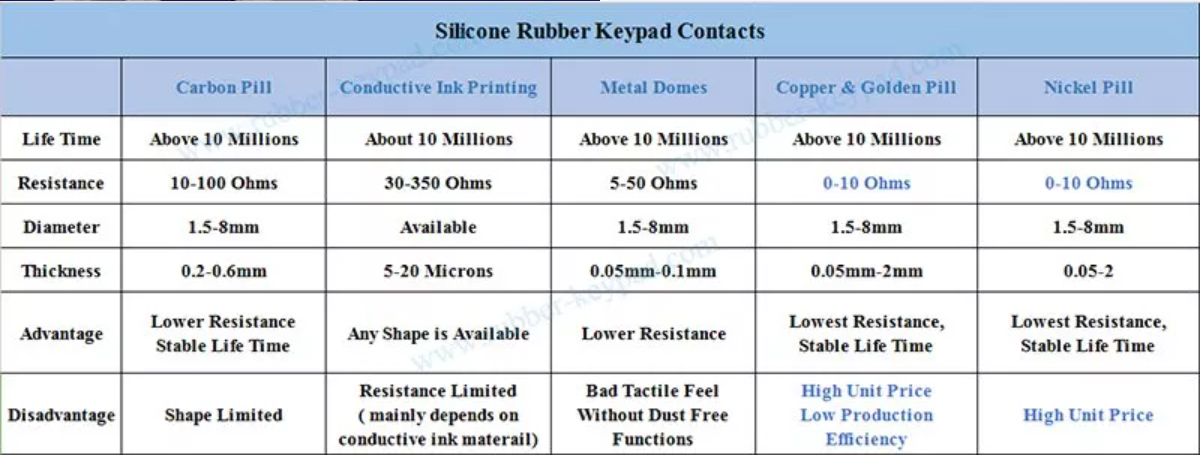

Silicone rubber buttons with nickel pills are a type of tactile interface commonly used in various electronic devices and control panels. These buttons are designed to provide a tactile and responsive feel when pressed, and the inclusion of nickel pills enhances their durability and conductivity.

The advantages of Silicone Rubber Buttons with Nickel Pills include:

- Tactile Feedback: These buttons are designed to provide distinct tactile feedback, allowing users to perceive whether the button has been pressed. This is crucial for usability and user experience in interface design.

- Durability: Silicone rubber material is known for its excellent wear resistance and durability. With the assistance of nickel pills, these buttons can endure thousands of presses and repeated use without damage or loss of function.

- Conductivity: Nickel pills possess good conductivity, ensuring effective electrical connections when the buttons are pressed. This makes them valuable in applications where signal transmission or function activation in electronic devices is required.

- Environmental Adaptability: Silicone rubber exhibits outstanding weather resistance and remains stable across a range of temperatures and environmental conditions. It is less affected by factors such as UV radiation, moisture, or chemicals, making it suitable for both indoor and outdoor applications.

- Dust and Waterproofing: Silicone rubber buttons can be designed to have dust and waterproof properties, making them suitable for harsh environments, such as industrial control panels or outdoor equipment.

- Customizability: These buttons can be manufactured in various shapes and sizes to meet the specific requirements of different applications. They can be customized to match design specifications, including color and labeling.

Silicone Rubber Buttons with Nickel Pills find wide-ranging applications:

- Electronics: These buttons are commonly used in various electronic devices such as remote controls, TV remotes, audio equipment remotes, and computer keyboards. They provide tactile feedback and durability, serving as a critical component of user interfaces.

- Industrial Control Panels: Silicone rubber buttons with nickel pills can be employed in control panels for industrial automation equipment. Their durability, resistance to contamination, and waterproofing make them suitable for factory environments where control devices endure harsh conditions.

- Automotive Controls: These buttons are frequently used in car interior control panels, including audio systems, air conditioning, and power window controls. They must be durable, reliable, and capable of functioning under different weather conditions.

- Medical Devices: Silicone rubber buttons can be found in medical devices, such as control panels for medical instruments and patient monitoring equipment. Their tactile feedback and hygiene performance are crucial in the medical industry.

- Consumer Electronics: Silicone rubber buttons with nickel pills are also widely utilized in consumer electronics such as mobile phones, tablets, and handheld gaming devices. They provide a user-friendly means of interaction on these devices.

- Outdoor Equipment: Due to their waterproofing and weather resistance, these buttons are suitable for outdoor equipment, including remote cameras, outdoor displays, and outdoor lighting fixtures.

- Military and Aviation Applications: In military and aviation sectors, silicone rubber buttons with nickel pills are used in control panels and equipment as they offer reliability and durability under extreme conditions.

- Power Equipment: They are also used in control panels for power equipment, such as generators and substation control systems, as they can function in high-temperature and electromagnetic interference environments.

Why Choose Us?

- Advanced Materials and Technology: Our factory boasts advanced silicone rubber synthesis technology, enabling us to customize the silicone rubber formulation for buttons to meet various requirements. We also employ high-precision mold manufacturing techniques to ensure that each button’s shape and size precisely conforms to specifications.

- Customer Customization: We focus on manufacturing silicone rubber buttons according to customers’ specific needs. Whether it’s different shapes, colors, patterns, or special logos, we can offer highly personalized solutions.

- Stringent Quality Control: In our factory, we implement stringent quality control procedures. Every button undergoes rigorous testing to ensure electrical conductivity and durability. Our quality standards adhere to international norms to ensure consistent high-quality products.

- Cost-Effective Manufacturing: Thanks to our efficient production processes and scale advantages, we can provide cost-effective manufacturing. This allows us to offer competitive prices to customers without compromising product quality.

Applications of Nickle Pills Silicone Rubber Buttons

- Consumer Electronics

- Computer Keyboards

- Industrial Control Panels

- Medical Devices

- Automotive Controls

- Aerospace and DefenseAppliances

- Remote Controls

- Gaming Devices

- Telecommunication Equipment

- Outdoors and Harsh Environments

- Consumer Appliances