Overview:

Silicone metal overmolding cooking utensil sets are premium kitchen tools crafted using advanced overmolding technology, combining durable stainless steel cores with high-quality, food-grade silicone. This process ensures a seamless bond between materials, providing ergonomic, heat-resistant, and non-slip handles for superior functionality and comfort. At our factory, we specialize in OEM and custom manufacturing, offering tailored designs to meet your unique requirements. With our expertise in silicone overmolding, we deliver exceptional quality and reliable performance for every product. Contact us today to create your custom utensil set!

Characteristics:

| Category | Details |

| Brand | OEM |

| Size | According to requests |

| Color | Black, Red, Blue, Yellow, Green, White, Purple, Pink, Custom |

| Design | Yes |

| Material | Eco-friendly food-grade silicone |

| Usage | Cooking |

| MOQ | Small order can be accepted |

| Testing | FDA/EU/LFGB/CIQ |

| Feature | Food-grade, Heat-resisting |

| Shape | According to function |

| Packing | Custom |

| Weight | Customized |

| OEM | Yes |

Benefits of Our Utensil Sets:

- High-temperature resistance ensures safe use in cooking and baking.

- Made from food-grade silicone, fully compliant for direct contact with food.

- Soft edges prevent scratches or damage to cookware surfaces.

- Multiple tools conveniently included in one versatile set.

Manufacturing Process:

- Material Preparation: High-quality stainless steel cores and food-grade silicone materials are carefully selected and pre-treated to ensure cleanliness and adhesion.

- Metal Core Fabrication: The metal components are precisely machined or molded into the desired shapes, ensuring durability and ergonomic design.

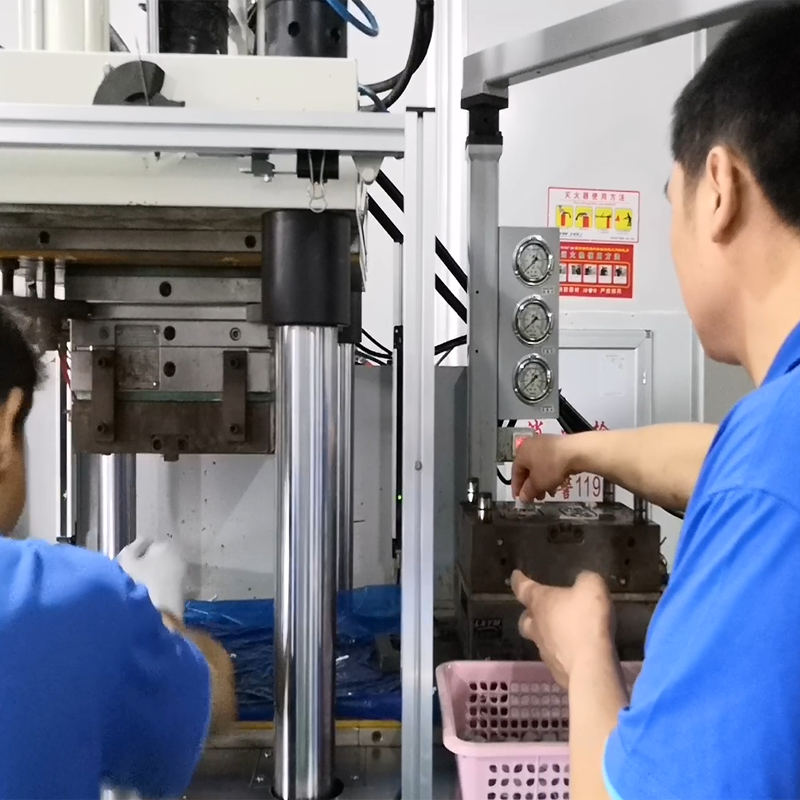

- Overmolding Process: The metal cores are placed into the mold, and liquid silicone is injected over them using advanced overmolding technology. This process ensures a seamless bond between the silicone and metal.

- Curing and Cooling: The molded utensils are cured at controlled temperatures to solidify the silicone and ensure optimal performance characteristics.

- Trimming and Finishing: Excess silicone is carefully trimmed, and the utensils undergo detailed finishing processes to ensure smooth edges and a polished appearance.

- Quality Inspection: Each utensil set is thoroughly inspected to meet stringent quality standards, including FDA, EU, and LFGB compliance.

- Custom Packaging: The completed utensil sets are packaged according to customer specifications, ready for shipment.

Our Factory:

We operate a fully equipped facility with state-of-the-art plants and machinery to ensure superior production quality. Our mold-making capabilities include advanced CNC, Mirror EDM, EDM, and Slow-speed Wire Cut WC, along with a range of auxiliary equipment.

Our production lines feature 15 rubber compression machines and 2 LSR injection molding machines. To ensure quality, we use precision tools such as 3D projectors, sealing testers, elasticity measurement devices, and durometers, supported by a skilled QC team.

In addition, our mechanical equipment includes AutoDryer lines, automatic screen printing machines, 3D measuring instruments, high-speed doming machines, die-cutting machines, and CNC machines.

This blend of cutting-edge automation, expert equipment, and strict quality control guarantees that we deliver products of the highest caliber.