Our one-stop service for Silicone Rubber Conductive Buttons with Carbon Pills encompasses a comprehensive support system, from concept to finished product:

- Customized Design: Our team collaborates with you to design silicone rubber conductive buttons that meet your specific requirements and specifications.

- Material Selection: We provide expert advice to assist you in selecting the most suitable silicone rubber materials and types of carbon particles for your application to ensure performance and reliability.

- Rapid Prototyping: To validate design and functionality, we offer rapid sample production and testing, ensuring the product meets your expectations.

- Custom Manufacturing: Once samples are approved, we initiate mass production to ensure you receive the required quantity of buttons promptly.

- Quality Control: We implement stringent quality control procedures to ensure the performance and reliability of each silicone rubber conductive button.

- Packaging and Delivery: We provide custom packaging options and ensure on-time delivery of products to your facility.

- After-Sales Support: Our customer support team is available to provide technical support, answer your questions, address issues, and ensure your satisfaction.

Whether you require small-scale custom production or large-scale batch manufacturing, our one-stop service covers the entire production process from the initial concept to the final product, ensuring you receive high-quality, reliable Silicone Rubber Conductive Buttons with Carbon Pills that meet your specific needs.

1. Offer 2D/3D Design drawings, Samples or tell us your basic information

2. Surface Demands: Legends Demands, Key & Button Color Demands, SprayColor Coating, Key-Setting

3. Protective Coating: PU Coating, Epoxy Coating, Matte Smooth, Plastic & Metal Keycap (Key Cover)

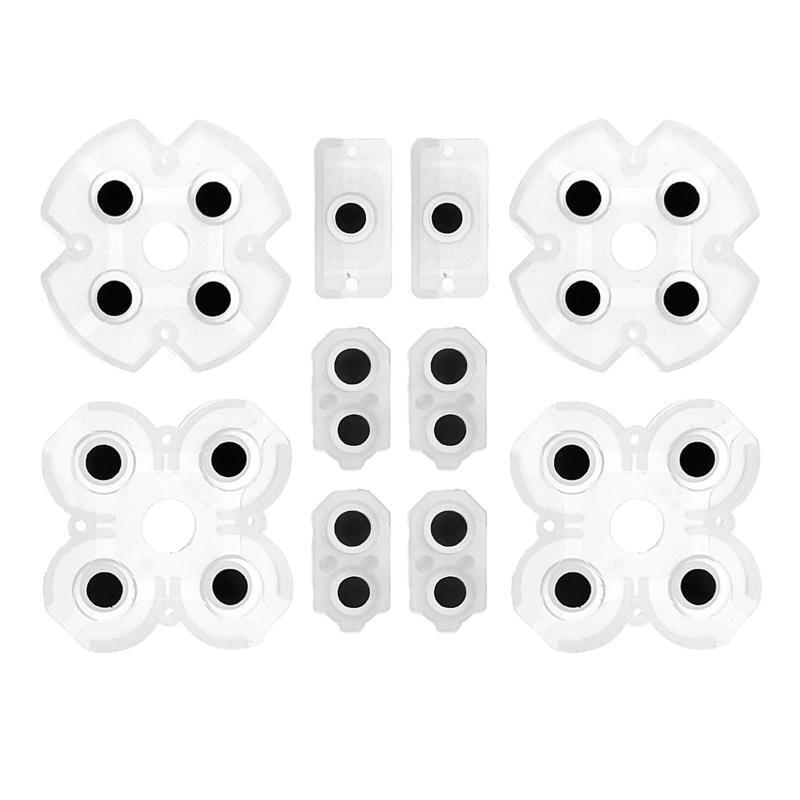

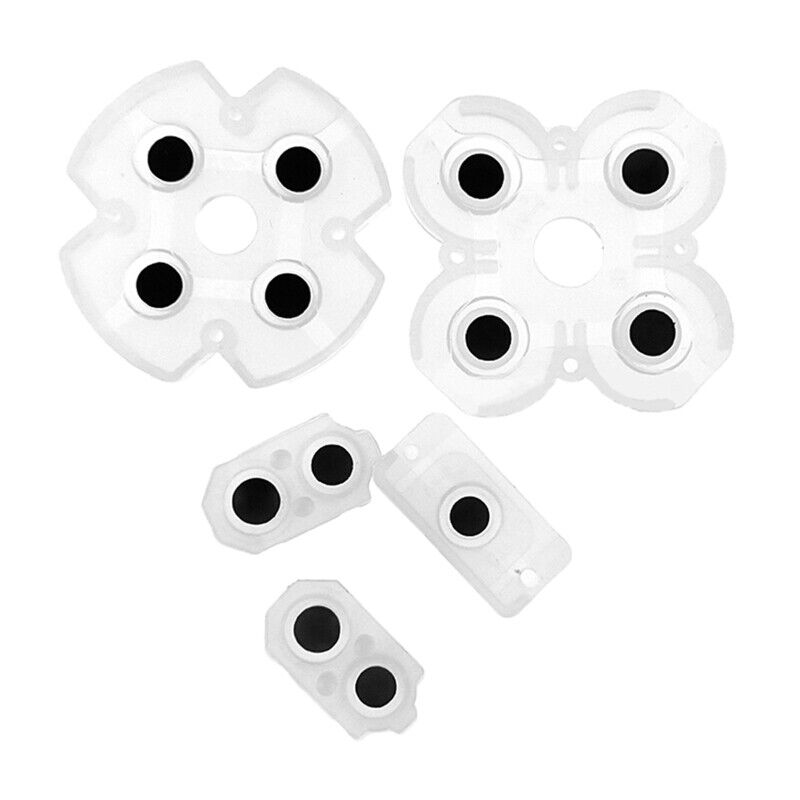

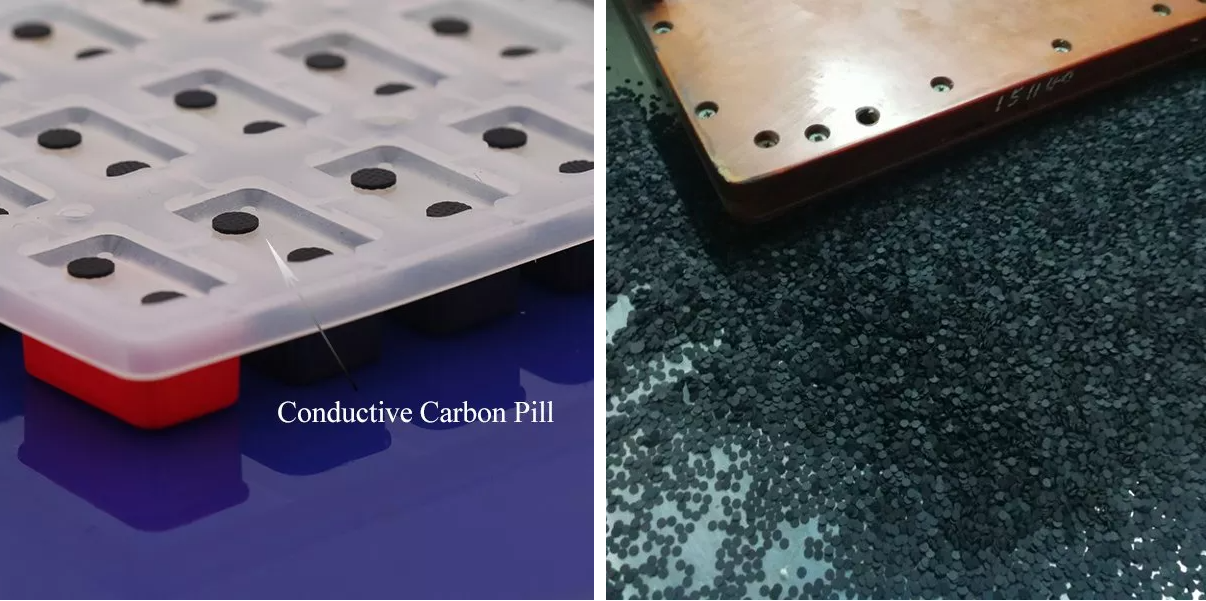

4. Electrically Contact Ways: Black Carbon Pills, Electrically Conductive Ink Prining, Metal Dome, Or only need Silicone Rubber Keypad Cover.

4. Contact Resistance: 10-250 Ohm

5. Actuation Force: 40g-300g

6. Quantity Demands: FOQ & EAU

| Conductive way | Life Time | Resistance | Diameter | Thickness | Advantage | Disavantage |

| Carbon Pills | Above 10 Millions | 10-100 Ohms | 1.5-8 mm | 0.2-0.6 mm | Lower Resistance Stable Life Time |

Shape Limited |

| Conductive Ink Printing | Above 10 Millions | 50-350 Ohms | Available | 10-20 Microns | Any Shape is Available | Resistance Limited |

| Metal Domes | Above 10 Millions | 1-100 Ohms | Available | 0.05mm-0.1mm | Lower Resistance | Bad Tactile Feel Without Dust Free Functions |

| Metal Pills | Above 10 Millions | 1-100 Ohms | Available | 0.05mm-2mm | Lower Resistance | Low Production Efficiency High Unit Price |

Our Advantage:

1. Precision Own Mold-Making Technology since 1998 year

2. Competitive Price

a. Own Mold-Making

b. Own Silicone Rubber Compression Plant

c. Own Plastic Injection Plant

d. Own Liquid Silicone Injection Plant (Dust-free)

e. Own Assembly Plant (Dust-free)

3. Quality Assurance: Production and Test according ISO9001:2008 standards

4. One Stop Service:

a. Experienced Technical Persons, Salesman & Workers

b. Deal with Keypad Mold Design, Mold-Making, Silicone Rubber Keypad, Screen Printing, Color Coating, PU Coating, Matte Smooth, Laser Etched, Epoxy Coating

c. Design&Sizes Test, Actuation Force Test, Backlighting Test etc.

5. Rapid Reaction Customer Service.