Tool & Mould Building

Our decades of tooling design expertise extend across various specialized areas, including plastic injection molding, LSR injection molding, plastic and LSR over-molding, silicone compression molding, and silicone and plastic extrusion. We take pride in exceeding the most stringent customer specifications and adhere to ISO 9001 and IATF 16949 quality management standards, ensuring that our results not only meet but surpass customer expectations.

Why Choose Us for Your Tooling Manufacturing

Through advanced equipment and technology, customized design and engineering support, high-quality materials and manufacturing standards, manufacturing efficiency and production cycle optimization, cost-effectiveness and long-term return on investment, as well as technological innovation and continuous improvement, we enhance the precision, complexity, and production efficiency of our tooling to meet the ever-evolving market demands.

Advanced Equipment and Technology

We possess advanced manufacturing equipment and technology, including high-precision CNC machines, CAD/CAM software, and 3D printing technology. These advanced toolings enable us to achieve precise manufacturing of tooling and accomplish intricate details and complex shapes with utmost accuracy.

Customized Design and Engineering Support

We work closely with our customers, gaining in-depth understanding of their needs and product requirements. Our experienced team of engineers provides professional design advice and engineering support, ensuring that the tooling design meets customer expectations and specific product requirements.

High-quality Materials and Manufacturing Standards

We strictly select high-quality materials for our tooling, such as premium-grade steel and wear-resistant alloys. Additionally, we adhere to strict quality control standards and processes to ensure the manufacturing quality and consistency of each tooling. This contributes to improved durability, stability, and lifespan of the tooling.

Technological Innovation and Continuous Improvement

As an innovation-driven and continuously improving factory, we constantly pursue technological innovation, exploring new manufacturing methods and materials. By incorporating advanced processes and technologies, we enhance the precision, complexity, and production efficiency of our tooling to meet the ever-evolving market demands.

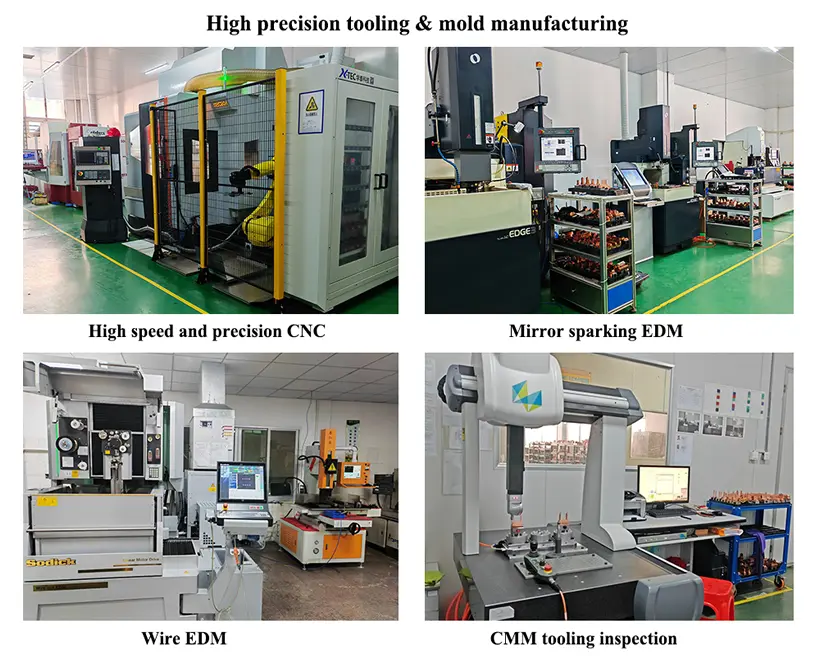

YJC's Main Tooling Manufacturing Machines

| Machinery | Quantity |

| High speed of 42000 and precision CNC | 2 |

| Other 7 CNC Machines | 7 |

| Makino Sinker EDM | 4 |

| Sodic Wire EDM | 5 |

| High Precision Grinder | 5 |

Tooling for Plastic and LSR Injection Molding

Designing tooling for complex plastic and Liquid Silicone Rubber (LSR) parts in injection molding is a highly technical and intricate process that demands precision and expertise. At YJC, we prioritize mold design as the core, providing exceptional solutions for the injection molding of intricate plastic and LSR components.

For plastic parts, we employ a meticulous approach to select the appropriate materials. Through advanced simulation software for flow analysis, we optimize the mold design to ensure reduced defects during the plastic filling process. Simultaneously, we excel in mold cooling techniques, effectively regulating the cooling process to enhance production efficiency while maintaining part quality.

In the realm of Liquid Silicone Rubber injection, we confront unique challenges. Our mold design controls the curing process to ensure precise part dimensions and performance. We carefully select materials compatible with LSR to prevent adverse reactions and ensure mold integrity and part quality.

Our commitment to continuous improvement keeps us at the forefront of injection molding technology, delivering innovative solutions that optimize production efficiency and elevate product quality.

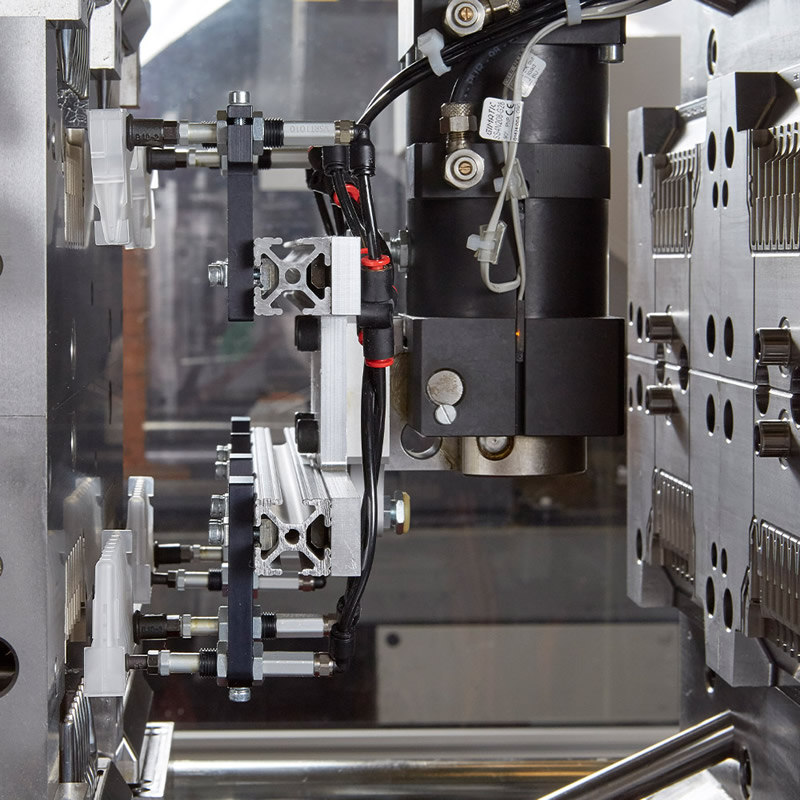

In-House Design and Tool Adjustments

Injection molders often rely on external tooling builders to custom-build the initial tooling. However, it's common for molds to require adjustments after qualification to ensure they meet all design specifications. Typically, injection molders send the mold out for final adjustments, which can take a significant amount of time, often a month or more.

At YJC, we take a different approach. We handle most of these adjustments in-house, allowing us to "fine tune" the tools after initial sampling. This enables us to improve the tool core/cavity geometry and achieve precise dimensions without lengthy delays.

High Precision Grinder

High Speed of 42000 and Precision CNC

High Speed of 42000 and Precision CNC

Makino Sinker EDM

Makino Sinker EDM

CNC Machines

Sodic Wire EDM

High Precision Grinder

Tooling for Over-molding

Precision Mold Design:

Our experienced engineering team utilizes advanced CAD/CAM software for precise mold design, tailored specifically for over-molding applications. By optimizing runner systems and cooling channels, we ensure uniform material flow and efficient cooling, resulting in superior over-molded part quality.

High-Quality Mold Materials:

Over-molding places unique demands on molds, and to meet these challenges, we carefully select high-quality mold materials like hardened steel or specialized alloys. These materials offer exceptional wear resistance, extending mold lifespan and enhancing production efficiency.

Advanced Manufacturing Technology:

Equipped with state-of-the-art CNC machines and EDM equipment, we achieve the highest level of precision and complexity in over-molding molds. This accuracy translates into over-molded parts with strict tolerances and consistent dimensions, meeting the exacting requirements of the process.

Customization and Flexibility: Over-molding projects can vary significantly, and our mold solutions are customized to cater to specific design and material needs. Our team collaborates closely with yours, ensuring seamless integration and optimal results.

By harnessing these advantages, our over-molding molds deliver outstanding performance, providing high-quality over-molded parts for your unique applications.

Tooling Manufacturing Application's Showcase

Sorry, we couldn't find any posts. Please try a different search.

"*" indicates required fields

Contact Us for Molds & Tooling Manufacturing

Our services includes injection mold, silicone rubber mold, LSR injection mold, and extrusion mold. Our mold service includes mold design and manufacturing. We will also provide parts design checking, mold and molding product cost quotation and full technical engineering support.