CNC Machining Service

Explore our online CNC machining service for custom parts

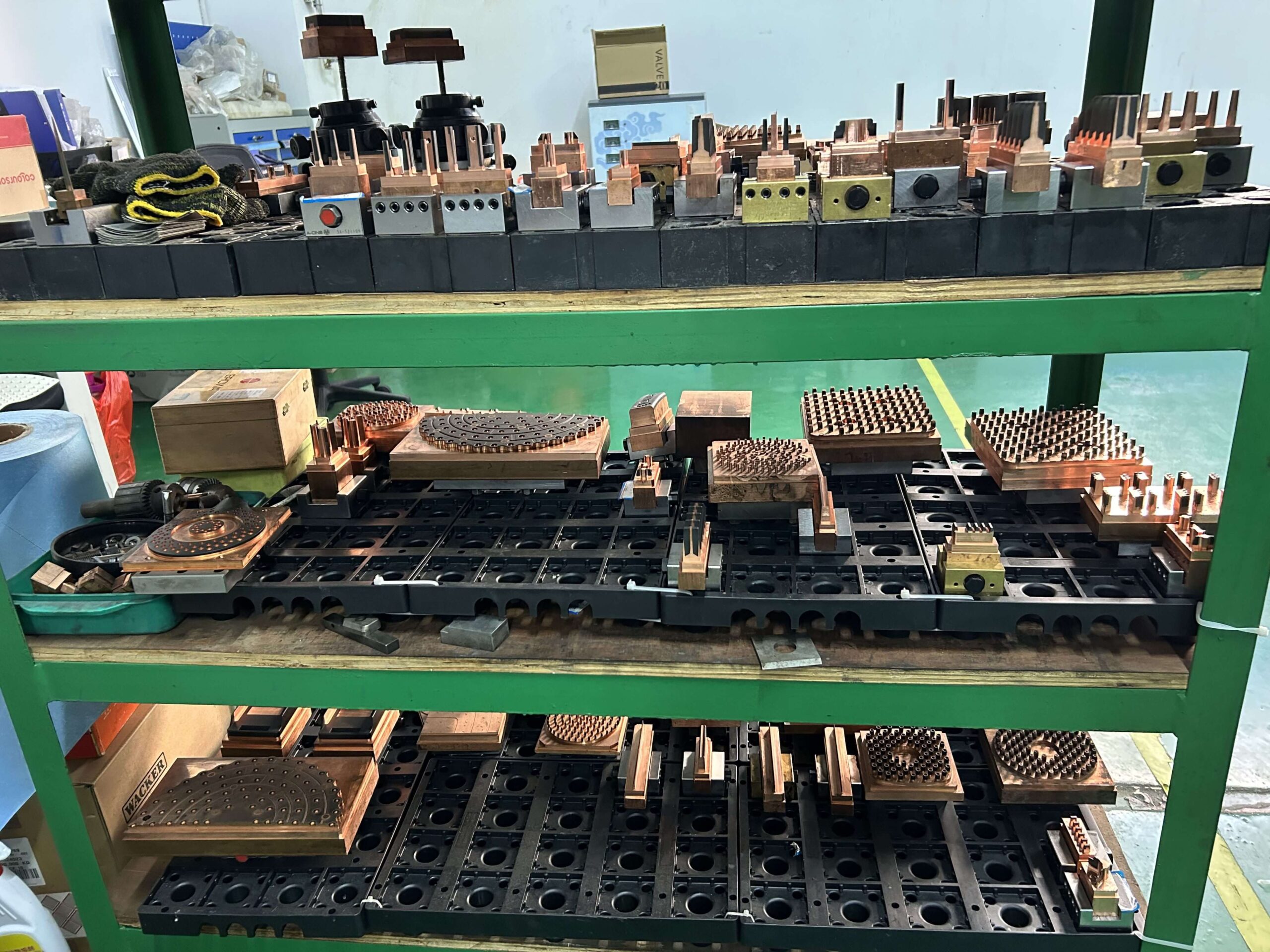

Our factory excels in CNC machining with its manufacturing expertise and advanced

technology, delivering precise and high-quality custom parts.

With our state-of-the-art CNC machining capabilities, our factory is equipped to handle complex designs and deliver high-precision custom parts with exceptional accuracy. Our experienced team utilizes advanced software and cutting-edge machinery to bring your unique concepts to life, offering unlimited possibilities for customization. Whether it's intricate geometries, tight tolerances, or specific material requirements, we have the expertise to meet your exact specifications and provide personalized solutions for your manufacturing needs.

Why choose Us for Custom Online CNC Machining Services?

Obtain instant quotes for personalized metal and plastic machined parts using our state-of-the-art Online CNC Machining Service. Experience rapid prototyping and fast production, ensuring your prototypes and production parts are ready within days. Rest assured of the highest quality as we are ISO 9001:2015 and ISO 16949 certified, demonstrating our commitment to meeting rigorous industry standards. Partner with us to streamline your projects and benefit from top-notch customer service. Get in touch now to kickstart your machining needs with efficiency and precision.

● Manufacturing& Delivery Capability

Equipped with advanced equipment and skilled operators, our factory has high production capacity, enabling efficient and scalable CNC machining for small to large batch sizes. We ensure on-time delivery of CNC machining projects, ensuring prompt delivery and customer satisfaction.

● Design Flexibility&Material Expertise

Our CNC machining capabilities offer design flexibility, allowing us to produce complex geometries, intricate features, and custom parts, providing innovative solutions for various applications. We excel in handling a wide range of materials, including metals, plastics, and composites, leveraging our expertise to select the most suitable materials for each project, ensuring outstanding performance and quality.

● Quality Assurance

Following strict quality assurance protocols, our factory conducts comprehensive inspections and tests at each stage of the CNC machining process, guaranteeing the highest quality and reliability of the finished products. With state-of-the-art CNC machines and meticulous quality control measures, we ensure precise and consistent results, meeting the highest industry standards and exceeding customer expectations.

● Technical Expertise

Our team of experienced engineers and technicians possesses extensive knowledge and expertise in CNC machining, providing valuable insights, technical support, and guidance to optimize designs and improve manufacturability. Through optimized processes, material utilization, and automation, our factory offers cost-effective CNC machining solutions, helping customers achieve their production goals within budget.

CNC Machining Process

CNC Milling

CNC milling is a computer-controlled machining process that uses rotating cutting tools to remove material from a work-piece, resulting in the creation of custom-designed components with high precision.

CNC Turning

CNC turning is a versatile and reliable machining process for creating cylindrical components with exceptional precision, surface quality, and efficient production capabilities, suitable for a wide range of industries and applications.

CNC Machining Materials

Metals

Aluminum

Brass

Copper

Stainless Steel

Steel Alloy

Steel Mild Low Carbon

Titanium

Plastics

ABS

Acetal

CPVC

HDPE

LDPE

Nylon

PEEK

PEI

PET

PMMA

Polycarbonate

Polypropylene

POM (Delrin)

PPSU

PS

PSU

PTFE

PVC

CNC Machining Capabilities

At yjcpolymer, we provide a comprehensive range of manufacturing capabilities through our in-house factories and extensive manufacturing partners . Whether you require rapid turnaround times and speed, or advanced capabilities and flexibility, our combined resources have you covered to meet your unique production needs.

CNC Machining Advantages

The subtractive process of CNC machining offers numerous advantages for both prototyping and production parts.

Precision and Accuracy

Versatility in Design and Production

Efficient and Rapid Manufacturing

Customization to Meet Unique Specifications

Consistent Quality and Reliability

CNC Machining Applications

CNC machining is extensively utilized in industries such as aerospace, medical, and automotive for its capability to efficiently produce accurate parts using production-grade materials. Typical CNC parts include:

Housings and Enclosures

Brackets

Manufacturing Fixtures

Gears and Bearings

Internal Mechanical Components

Medical Instruments