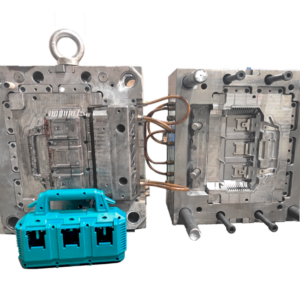

The PTC box is made by PA66+GF which contains 4 middle screw nuts and 6 tiny screw nuts. The box is used for heating the battery of NEVs.

When the NEVs are used in winter,the low temperature could lead the auto motor to stop working,the PTC box would keep the battery working during the car was driving.

Specifications:

| Name | New Energy Vehicles Battery Heater Box |

| Material | PA66+GF |

| Dimension | Customized |

| application | car battery |

| Working Temperature | -20~200℃ |

| Surface Treatment | sandy finish |

| Housing Color | Black/Blue |

| Standard | LKM |

| Weight | 510g |

| Mould Precision | +/-0.05mm |

Applications

PTC Injection Moulding Automotive Parts have a wide range of specific applications in the automotive industry, covering critical areas such as battery management, circuit protection, temperature control, stability control, lighting systems, and engine management, all contributing to improved vehicle performance, safety, and reliability.