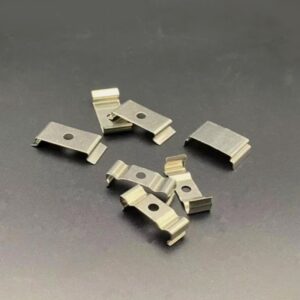

Precision OEM/ODM Metal Sheet Automobile Manufactured By Stainless Steel

Overview:

Our precision sheet metal automobile components are expertly crafted from high-quality stainless steel using advanced metal stamping techniques. This process ensures exceptional accuracy and consistency in every piece. Stainless steel’s inherent strength and resistance to corrosion make it an ideal material for automotive applications, guaranteeing longevity and reliability. Our metal stamping process allows for the creation of intricate shapes and designs, meeting the demanding specifications of the automotive industry while maintaining cost efficiency and high production standards.

Features:

| Product Feature | Description |

| Quotation | Based on your drawing (size, material, thickness, processing content, and required technology, etc.) in formats such as PRO/E, AutoCAD, SolidWorks, UG, CAD/CAM/CAE, PDF. |

| Materials Available | Stainless steel, aluminum, alloy, iron, brass, galvanized, copper, etc. |

| Surface Treatment | Anodizing, blackening, electroplating, painting, powder coating, passivation, carburizing, etc. |

| Finish | Polished, mirror polished, brushed, sandblasted, heat-treated, etc. |

| Tolerance | +/- 0.002 mm or +/- 0.00008 inch |

| Surface Roughness | Ra 0.4 (milled or turned without polishing or grinding) |

| Color | Anodized (black, silver, blue, gold, red, green, pink, etc.), painting (all colors) |

| Logo Method | Laser engraving, CNC engraving, screen-printing, etc. |

| Application | Automotive, motorcycle, bicycle, aviation, electronics, medical, home appliance, machinery, etc. |

| Acceptance Standard | 100% based on production drawings or samples |

Surface Treatment:

- Electroplating:

– Applies a thin metallic coating to precision sheet metal components, enhancing corrosion resistance and delivering a polished appearance.

- Powder Coating:

– Provides a durable and vibrant finish to sheet metal parts, combining aesthetic appeal with effective protection against environmental factors.

- Anodizing:

– Develops a robust oxide layer on the surface of the sheet metal, offering superior corrosion resistance and a sleek, decorative finish.

- Brushed Finish:

– Produces a textured surface through brushing, imparting a refined and modern look to automotive sheet metal components.

- Polishing:

– Enhances the visual appeal of the sheet metal by smoothing and shining the surface, resulting in a high-gloss, reflective finish.

- Passivation:

– Improves corrosion resistance by removing surface impurities, thereby extending the longevity and performance of precision sheet metal parts.

OEM/ODM Services for Stainless Steel Sheet Metal Automotive Parts:

- Custom Design and Engineering:

– Develop bespoke designs tailored to automotive requirements.

- Material Selection:

– Select appropriate stainless steel grades based on performance needs.

- Prototype Development:

– Create prototypes to validate design concepts before full-scale production.

- Precision Metal Stamping:

– Use advanced stamping techniques for high-accuracy parts.

- Surface Finishing:

– Offer treatments like electroplating, powder coating, anodizing, and polishing.

- Quality Assurance:

– Implement rigorous quality control and testing to meet specifications.

- Custom Packaging:

– Provide tailored packaging for safe and secure transportation.

- Logistics Management:

– Manage supply chain and offer flexible shipping options.

- After-Sales Support:

– Provide dedicated support to address post-production issues.