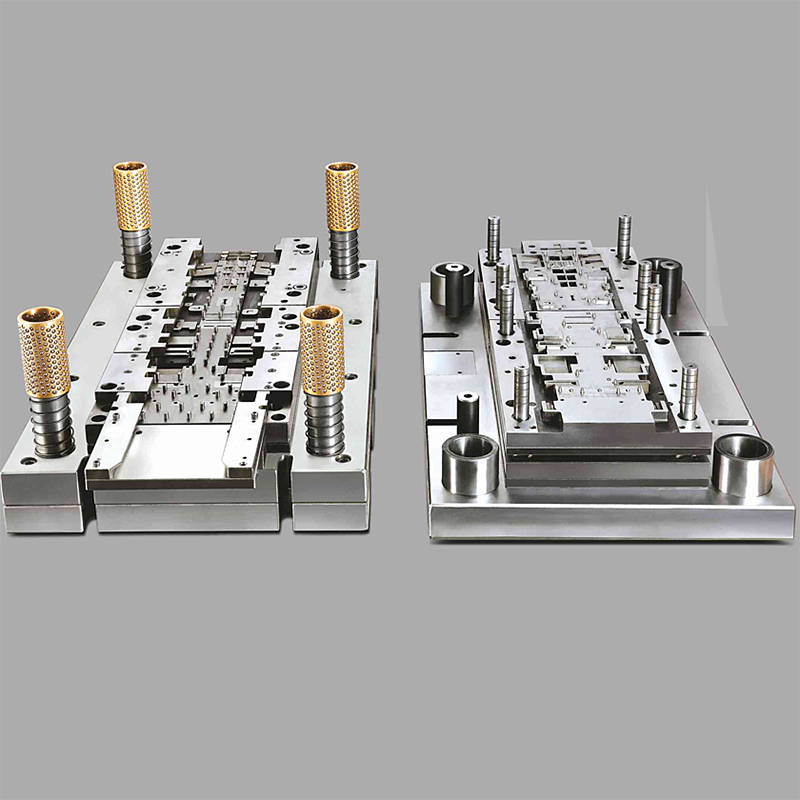

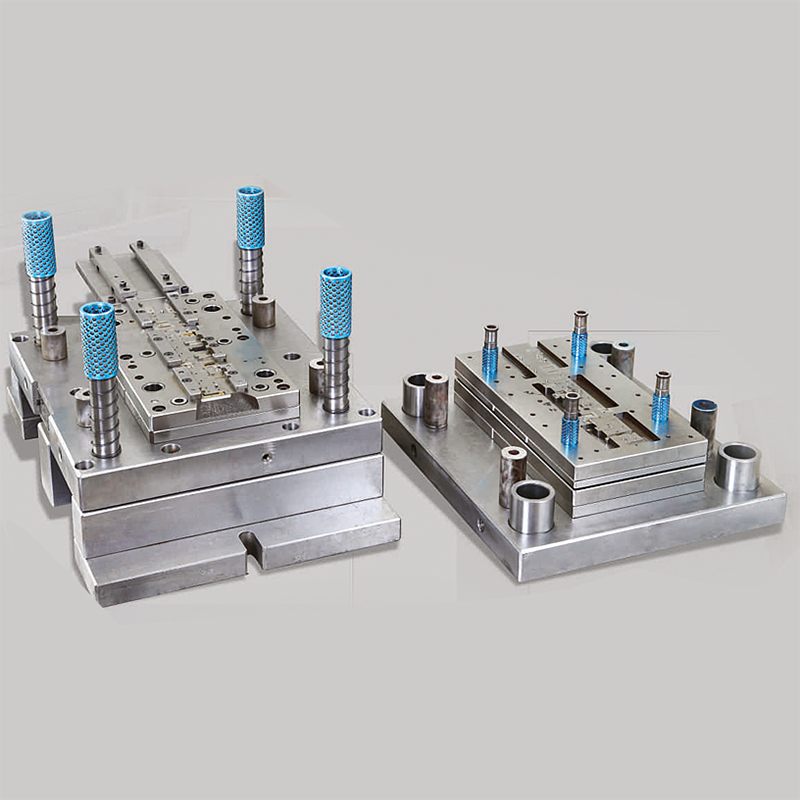

Precision Metal Stamping Tools Stamping Die in Manufacturing

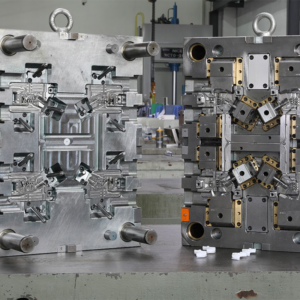

From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping. Our dedicated team of skilled engineers offers a full injection mould tool design service with considerable experience including single cavity, multi-cavity, hot runner, over-mould, and 2k tooling.

Our Main Products:

Steel metal stamping tools, sheet metal stage stamping tools, steel metal stamping progressive tools, steel metal stamping tools for home appliance, steel metal stamping tools for auto parts, steel metal stamping tools for hardware, steel metal motor core die etc.

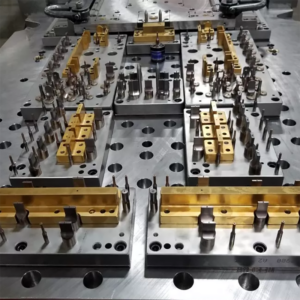

Different Types of Stamping Dies

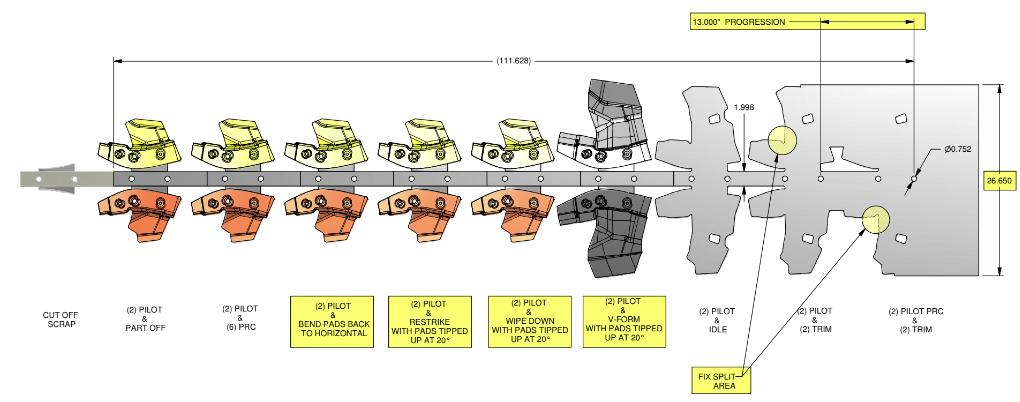

There Is A Diverse Range Of Die Types Used For Metal Stamping, Each Of Which Perform Different Operations, Such as Cutting, Trimming, Notching, Blanking, Piercing, Lancing, and Shearing. Types Of Stamping Dies Include:

- Blanking dies

- Compound dies

- Forming dies

- Coining dies

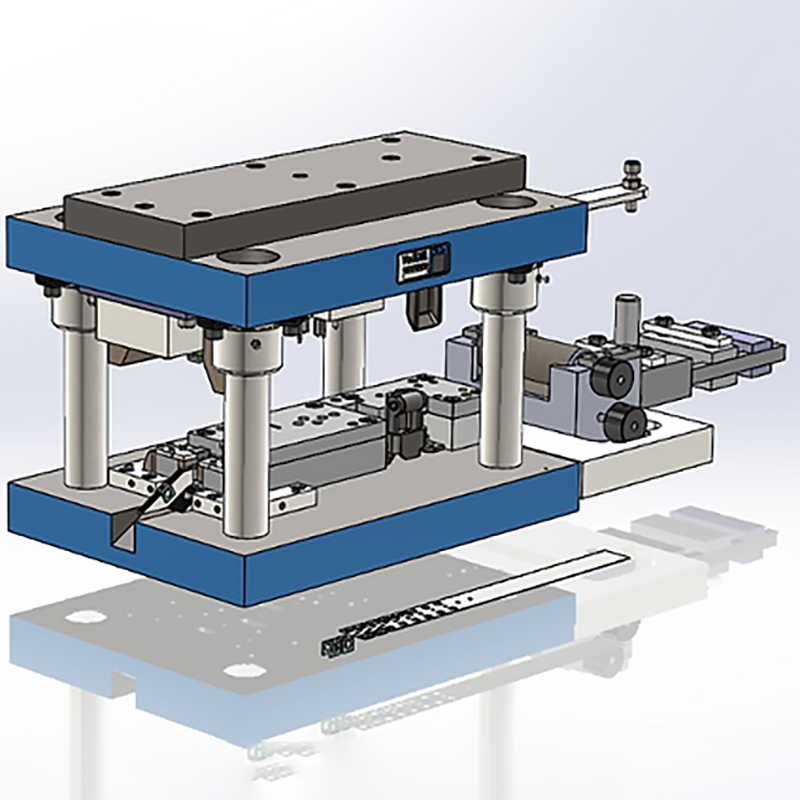

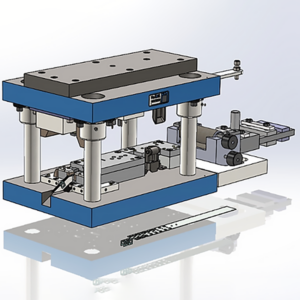

- Progressive dies

Progressive dies offer many benefits when compared to other die types as they allow for high production volumes. The progressive die stamping process is capable of performing multiple cutting and forming operations at once and can quickly produce accurate and consistent parts.

YJC Offers Many Unique Features to Remain Competitive Within the Industry Incluing:

YJC Offers Many Unique Features to Remain Competitive Within the Industry Incluing:

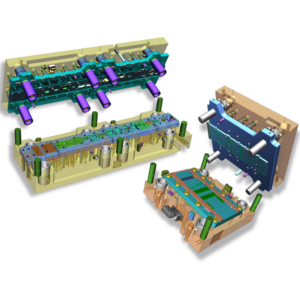

- Full die design and development for unrivaled personalized production

- Sharpening and maintaining tools to ensure consistency and design accuracy

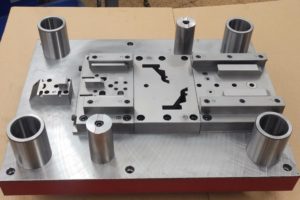

- EDM and CNC machining for the tightest tolerances on the market

- Reverse engineering and diagnostics to ensure quick fixes when production errors arise, no unexpected delays, and smoother production

- Solidworks and LogoPress software

- Competitive pricing

- Rapid production and delivery

- Professional, streamlined experience from start to finish for every customer

- Secondary operations, laser cutting, bending, forming, welding, and more

Uses of Metal Stamping Dies

Metal stamping is commonly used for a variety of applications. It is a versatile process capable of producing large volumes. Custom metal stamping dies are diverse and can be configured to create parts for multiple applications, including:

- Home Appliances

- Fasteners (washers, brackets, metal clips)

- Lighting

- Telecommunications

- Medical Equipment

- Electronics

- High-security Locks

- Agricultural

- Furniture production

- Ventilation (duct accessories, rain caps, duct hangers, gates, valves, etc.)

We Provide:

- Over 20 years of combined tool & die experience

- Precision custom tool & die design services – tolerances of less than 0.001 of an inch

- Tool & die manufacturing for our equipment or yours

- Tool & die repair services

- Stamping, single hit, progressive, transfer, coining, forming, draw, blanking, secondary, hand transfer, swaging dies and In-die electronic sensors

- ISO 9001-2015 certified

Why Choose YJC?

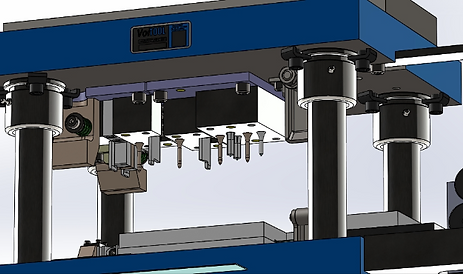

1.Micron-Level Tooling

Lingshantech cooperates with many-sided tooling manufactory technology, can achieve micron-level in tool manufacturing, and it perfectly achieved required precision for LSR tool. By using AR BURG、2KM etc. manufacturing equipment, we can make ultra-precision LSR products with weight minimum to 0.01g,thickness minimum to 0.05mm.

2.Advanced Equipment

Lingshantech has 60 ton – 160 ton LSR injection molding machines 10 sets,3000 square feet injection molding room including 250 square feet M8 class clean room.We can produce parts from 0.01pound to 13 pounds.

3.In House Mold Making Shop

Lingshantech has In-house tooling – fully equipped 6000 square feet tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.

Tooling Making Equipment

| Machinery | Quantity |

| High speed of 42000 and precision CNC | 2 |

| Other 7 CNC Machines | 7 |

| Makino Sinker EDM | 4 |

| Sodic Wire EDM | 5 |

| High Precision Grinder | 5 |