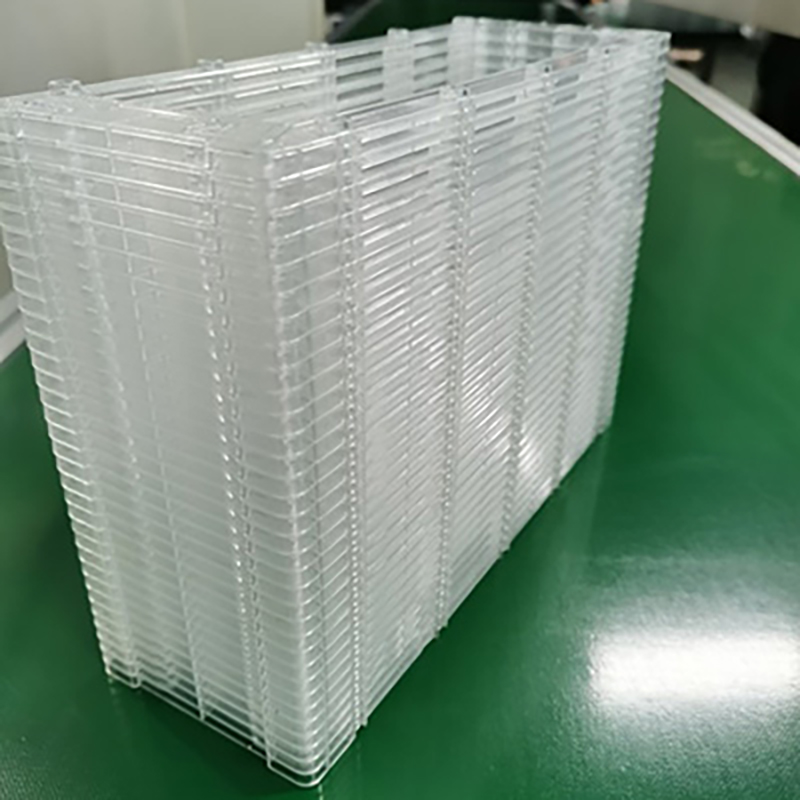

Precise Clear Plastic Injection Molding Service for New Energy Components

Precise Clear Plastic Injection Molding Solution for New Energy Components is a comprehensive and integrated approach to meet the specific needs of clients in the new energy sector. This solution encompasses the entire product development and manufacturing process, ensuring efficiency, quality, and cost-effectiveness from concept to production. Here’s a detailed expansion of our service:

- Conceptualization and Design

- Material Selection

- Prototype Development

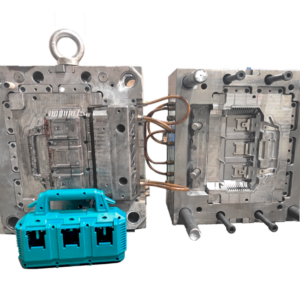

- Precision Tooling

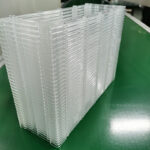

- Injection Molding

- Surface Treatments

- Quality Assurance

- Assembly and Packaging

- Sustainability Practices

- Cost Control

- Timely Delivery

| Product pre-analysis | 1.Part Injection molding Feasibility Analysis(DFM) 2.Run mold flow analysis |

| Mold design | A. Specific 2D assembly drawing B. 3D assembly drawing C. Drawing of parts and loose items D. Mold BOM sheet and purchase order |

| Mold making | A. Release of drawings B. CNC mold core C. Mold and accessory processing D. Mold assembly |

| Mold Trial | A. Material and machine preparation B. Making samples with machines C. Mold testing report |

| QI | A. Product dimensions and assembly test B. Product improvement report C. Functional test and improvement report |

The material selection for Precise Clear Plastic Injection Molding for new energy components typically involves the choice of the following common materials to meet their specific requirements:

- Polycarbonate (PC)

- Polymethyl Methacrylate (PMMA)

- Polystyrene (PS)

- Styrene-Acrylonitrile (SAN)

- Polyether Ether Ketone (PEEK)

- Other Engineering Plastics

Material selection is typically based on the specific requirements of new energy components, including transparency, chemical resistance, temperature stability, and mechanical performance. Manufacturers often decide on the most suitable material based on these requirements to ensure that new energy components perform well in various environments and applications.

Precise Clear Plastic Injection Molding Parts has a variety of specific applications in the field of new energy components, including but not limited to the following areas:

- Solar Components: Transparent covers for solar panels, which protect the cells and allow sunlight to pass through for power generation.

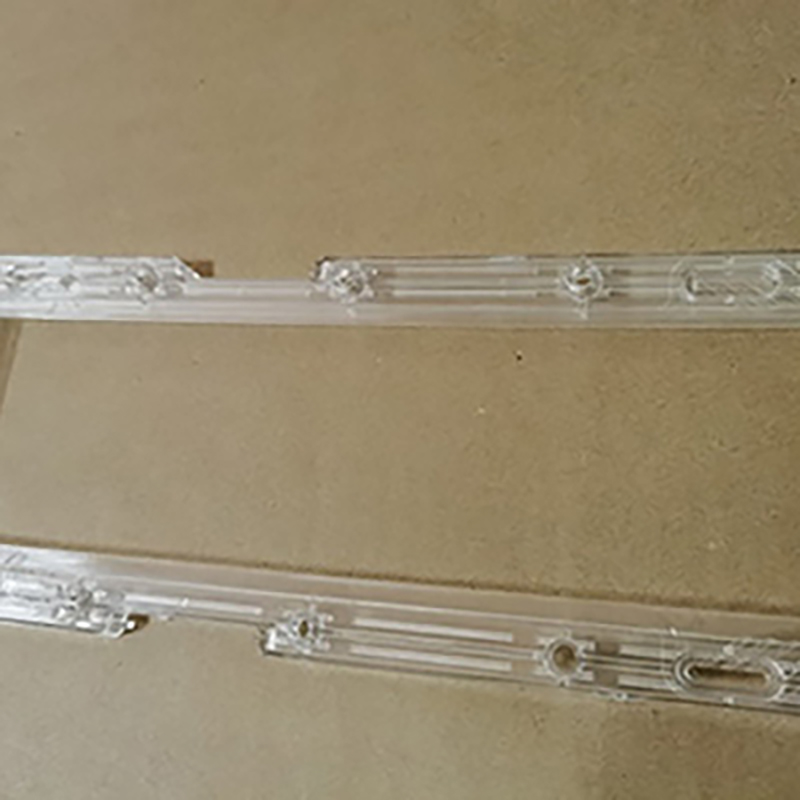

- Optical Elements: This includes lenses, optically clear reflectors, and light guides used for concentrating and distributing light to enhance energy efficiency.

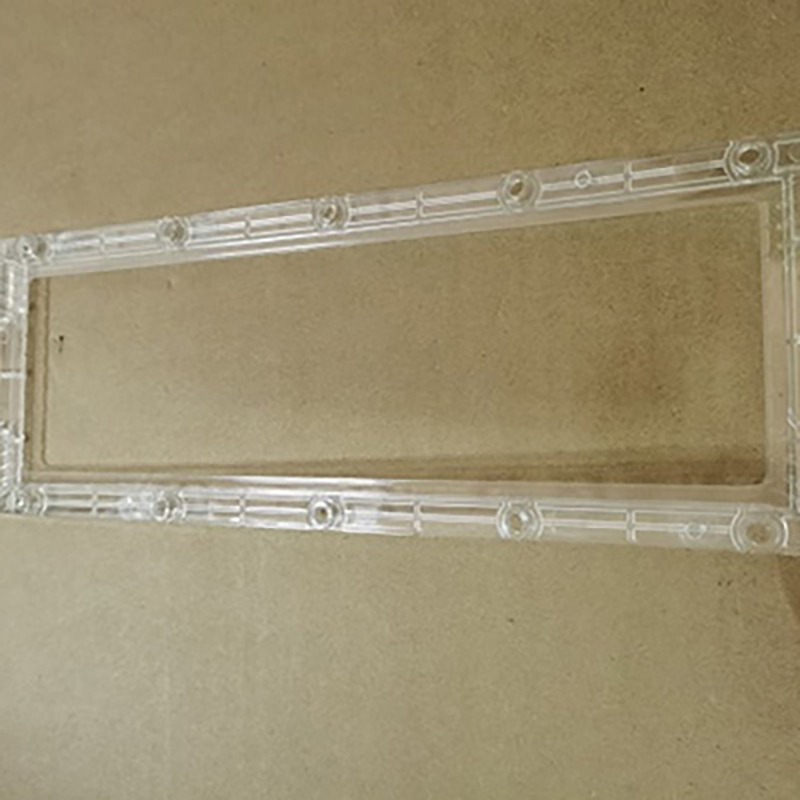

- Battery Housings: Clear casings for use in battery technologies, such as lithium-ion batteries or other energy storage devices, providing protection and visual transparency.

- Lighting Applications: Transparent components for use in fixtures and lighting systems, such as lampshades, lenses, and light guides to achieve even light distribution.

- Electronic Displays: Transparent display panels, touchscreens, and display covers used in applications like the dashboards of new energy vehicles and battery management systems.

- Medical Devices: Transparent components and windows used in medical devices for sensors, detection, and monitoring systems.

- Green Building: In the realm of green building, transparent external walls, shading devices, and daylighting systems are employed.

- Electric Vehicles: Transparent components in electric vehicles, including battery enclosures, charging ports, and windows, to enhance energy efficiency and vehicle performance.

These applications demonstrate the diversity and significance of Precise Clear Plastic Injection Molding in the field of new energy. Transparency and precision are crucial for these components as they need to meet high standards in terms of protection, performance, and aesthetics.