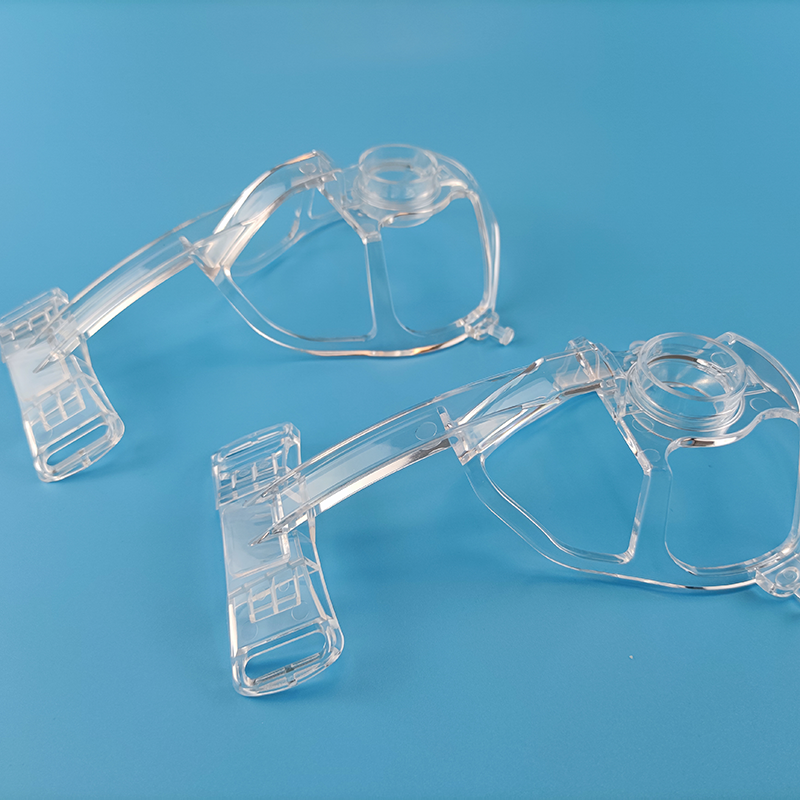

Injection Molding Plastic Medical Devices Parts

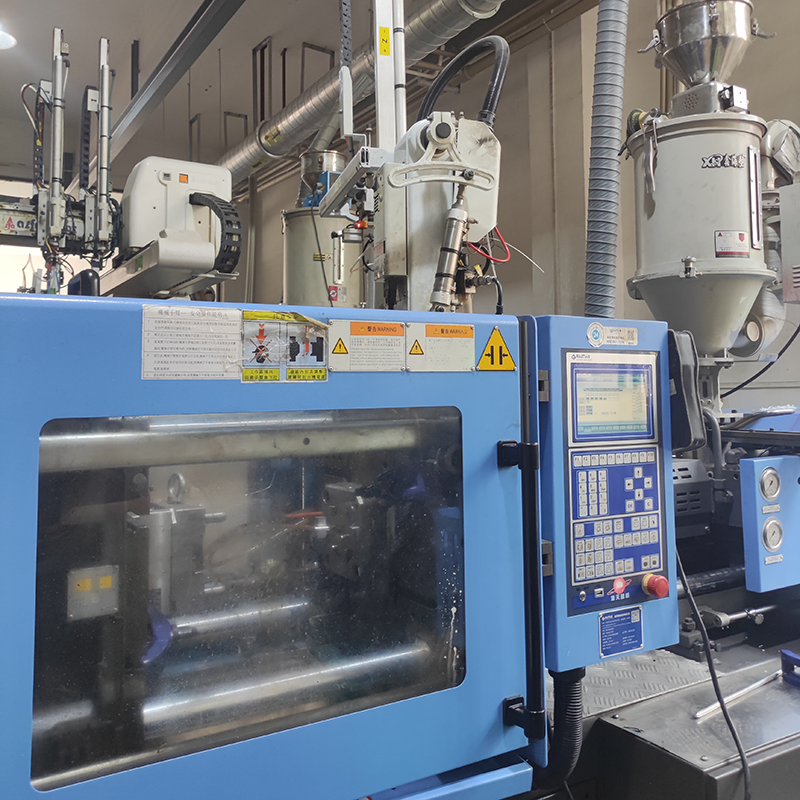

Our factory offers a one-stop injection plastic medical parts, covering design, mold manufacturing, raw material procurement, silicone molding, quality control, packaging, and supply chain management.

Advantages of Plastic Injection Molding for Medical Parts

A Wide Range of Material Choices

The injection molding procedure offers the widest range of options for choosing materials. Although medical injection molding narrows the scope of injection molding materials, there are still many materials that are suitable for manufacturing medical-grade components. We’ll touch on that more in the later parts of this guide.

Cost-Efficiency

The way the medical plastic injection process is set up helps cut unnecessary injection molding costs — massive production deliveries and high-volume manufacturing help to maximize the process. Hence, whenever there is an extraordinary volume of medical injection parts being produced, the injection molding process can reduce the cost per part.

Durability

A known fact about plastics used in injection molding is that it is ruggedly durable. These materials provide dogged strength and resistance to adverse environments and usage. Therefore, the products of this process can comfortably withstand heat, blunt force, and vibration without any incidence of cracks or breakages. Also, when they undergo sterilization in autoclaves, they don’t cave to the heat.

Exceptional Accuracy

In the process of plastic injection for the medical device industry, exceptional accuracy is a must. Due to the tight tolerance margin, every inch, millimeter, or centimeter count can influence the whole molding development. Besides, it is essential to use skilled injection molding facilities to achieve this high-level accuracy.

Resistance to Contaminants

The materials utilized in this production process easily withstand the invasion of contaminates. Also, they don’t need much sterilization to stay germ-free. Because of this factor, the material easily meets the FDA standards and other stipulated requirements.

Plastic Injection Molding Application in the Medical Device Industry

The application of plastic molding injection in the medical device industry is diverse. Medical suppliers go for this process as the products easily attain the stipulated standards of quality and safety. Besides, medical device plastic injection molding comes in handy in areas like:

- Equipment for Dental X-ray

- Orthopedics

- Components and equipment for drug delivery

- Lab supplies like test tubes, beakers, and other containers

- Prep equipment for surgery and surgical implements

- Housings, casings, and enclosures for medical and lab equipment

The Common Plastic Materials Used in Medical Injection Parts

- Polypropylene (PP)

- Polyethylene (PE)

- Polystyrene (PS)

- Polyetheretherketone (PEEK)

Common Types of Injection Molding Techniques Used to Manufacture Medical Device

- Thin wall molding

- Gas-Assisted Injection Molding

- Metal Injection Molding

- Liquid Silicone Injection Molding

Advantages of YJC’s Injection Molding

- Production Grade Tooling: Production-grade steel tooling .

- Broad Material Selection: Choose from dozens of materials including ABS, Ultem, PC/ABS, PEEK, HDPE, PET, TPE, PET, nylon, polyethylene, and more

- Precision: Industry-leading delivery on tight tolerance projects

- Scalability: Mold prototypes or production runs of millions of parts

- Wide Range of Machines: Single, multi-cavity, and family molds; 50 to 1,100+ press tonnage; side actions including hand-loaded cores available