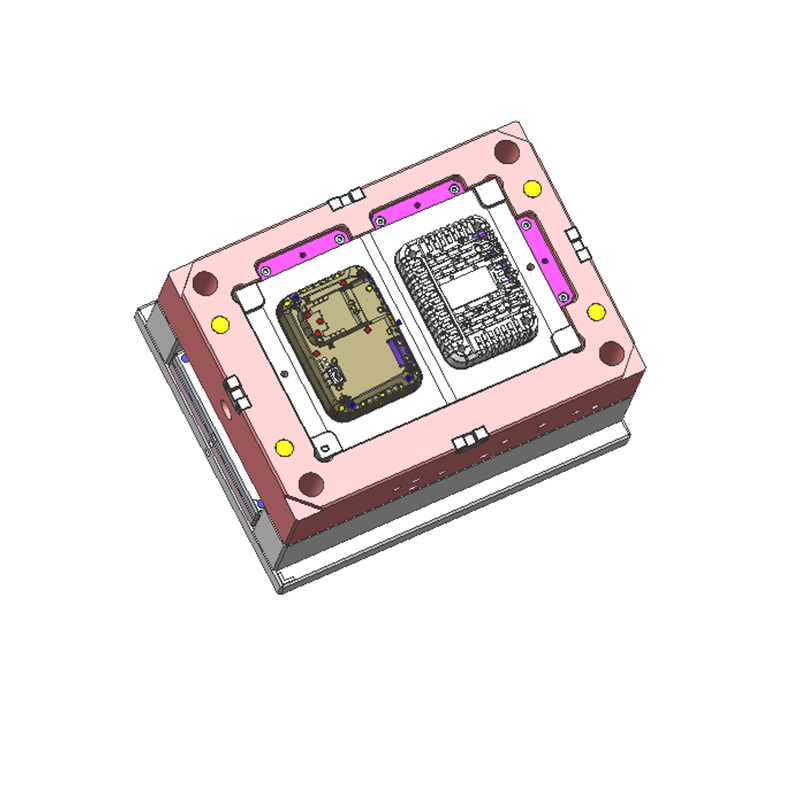

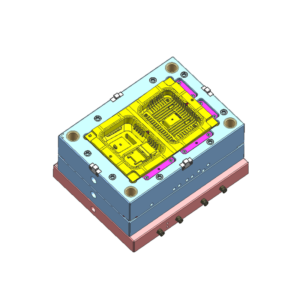

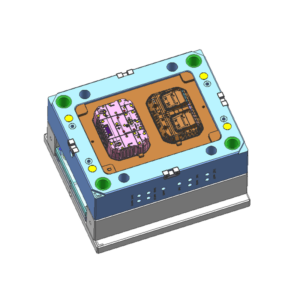

Plastic Injection Mold Suppliers Plastic Precision Battery Case Mold

Crafted by leading Plastic Injection Mold Suppliers, Plastic Precision Battery Case Mold redefines excellence in battery case production. Its innovative design encompasses advanced features, including cooling channels for optimal temperature control, sliding blocks for intricate sections, and a seamless ejection mechanism. Meticulously constructed from high-quality tool steel, our mold ensures durability and precision with every cycle. Elevate your manufacturing process with a mold that not only meets but exceeds industry standards. Trust in our expertise for a battery case mold that sets new benchmarks in quality and performance.

The Art of Mold Construction:

- Design and Construction:

The production journey commences with meticulous mold design and construction. Optimization is key, ensuring components can be molded seamlessly and aligning with the subsequent construction of the mold.

- Testing and Modification:

Rigorous testing and potential modifications precede the handover to the mold production department, ensuring the highest quality and functionality.

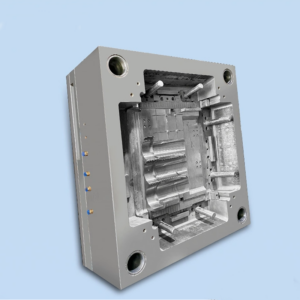

- Material Choices:

Traditional yet resilient, steel remains the primary material for mold construction. High-quality tool steel is employed for cavities, core inserts, ejector pins, and other critical components.

- Friction Considerations:

Different steel grades are strategically chosen based on frictional wear and tear. Hard tool steel is reserved for components enduring stress, while milder steel is employed for parts where friction is less critical, optimizing overall costs.

In essence, our Plastic Precision Battery Case Mold production delves into a realm where precision meets efficiency. From intricate mold design to the selection of materials, our commitment to excellence ensures the seamless production of battery case molds tailored to meet the highest industry standards.