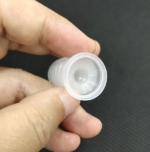

Details:

Material:Silicone/rubber

Technology:Vulcanized Compression Molding

Hardness:20~50 ShoreA

Service:OEM/ODM

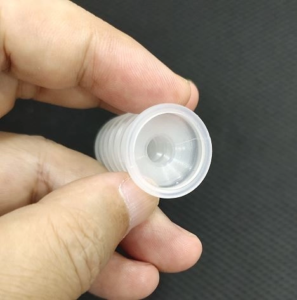

The OEM Moulding Silicone Telescopic Bellows in the bathroom have various specific applications:

- Shower Systems: These telescopic bellows can be used between the showerhead and the shower hose to ensure smooth water flow while protecting the internal pipes from moisture and humidity. They can also reduce wear and tear on the shower hose, extending its lifespan.

- Faucets: At the connections of faucets, telescopic bellows can provide sealing to prevent water leakage and ensure proper water flow. This is essential for maintaining the performance of faucets.

- Sink Drain Systems: These bellows can also be used for the flexible connections in sink drain systems to ensure proper drainage while preventing water from seeping into the drain pipes.

- Bathtubs: In the drainage system of bathtubs, telescopic bellows can be used to seal and protect the drain pipes, preventing water leaks and the intrusion of moisture into the bathroom structure.

- Other Applications: In addition to the above-mentioned uses, these telescopic bellows can also be used in other bathroom equipment, such as toilet sinks, bathroom basins, washing machine drainage systems, and more. They ensure that these devices have the necessary flexibility and sealing during use.

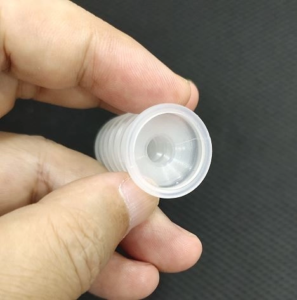

Rubber bellows require a material with a high density that effectively prevents media leakage.

The chosen rubber bellows material should possess suitable mechanical strength and hardness.

It is essential for the rubber bellows material to exhibit excellent compressibility and resilience while maintaining minimal permanent deformation.

The rubber bellows material must withstand high temperatures without softening, resist decomposition, remain pliable at low temperatures, and avoid becoming brittle.

The material for rubber bellows should demonstrate exceptional corrosion resistance, allowing for prolonged operation in the presence of acids, alkalis, oils, and other aggressive media, while maintaining minimal changes in volume and hardness. Additionally, it should not adhere to metal surfaces.

Rubber bellows material should exhibit a low friction coefficient and exceptional wear resistance.

It should possess the flexibility required for proper sealing surface engagement.

Rubber bellows must demonstrate excellent aging resistance and durability.