Material:NBR,EPDM,SILICONE,FKM,SBR,NR,etc.

OEM / ODM:Available

Hardness:20-90 Shore A

Size:As per drawing dimensions

Tolerance: +/-0.02 mm

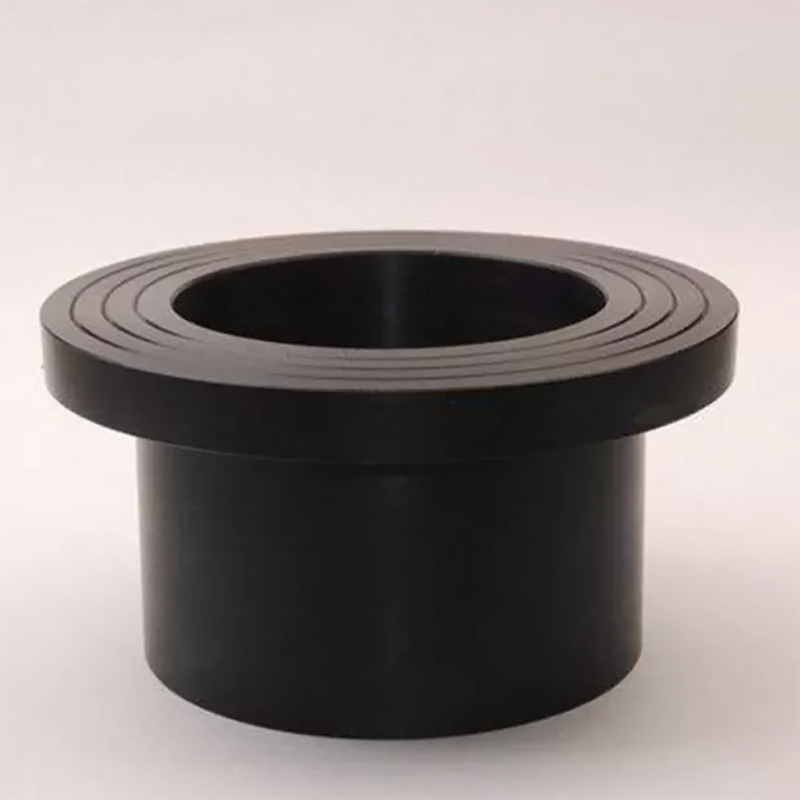

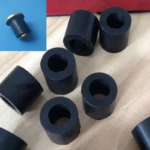

Silicone Sleeve Bushings are excellent protective products due to their materials’ vibration resistance and the patterned surface of the sleeves, which is designed for use in plain bearings, pipes, tubes, and flanged bearings. These bushings protect components from excessive friction and shock, thereby preventing the need for complete part replacements and extending the machine’s lifespan.

Silicone Sleeve Bushings serve as effective shockproof and breakage-proof elastomeric rubber sheaths, functioning as rubber dampers or bumpers.

These bushings can be manufactured from 100% eco-friendly silicone, making them non-toxic, abrasion-resistant, and capable of withstanding high temperatures. They are primarily used in medical devices, suspension systems, and industrial machinery, among other applications.

One-stop service:

1. We have a complete production line, including mold making, silicone rubber compression, LSR injection and assembly.

2. With advanced equipment and complete testing equipment, the factory has obtained ISO9001 international quality system certification.

3. Accurately control the sleeve and the size deviation of bushing to ensure that the tolerance of finished products is controlled within the scope required by the drawing.

4. If the parting line or flash is found to be too large during the processing, the molding process will be adjusted and improved in time to ensure that the design standards are met.

5. Overseas sales team will provide you with a full range of services, including customs clearance, shipping and delivery