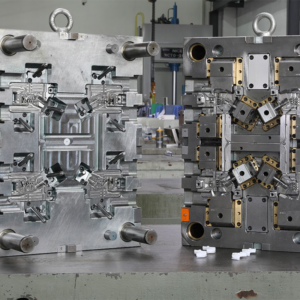

Custom Tool & Die Design and Making for Sheet Metal Stamping

YJC provides precision, high-quality, reliable and cost-effective single precision metal stamping tools, steel metal stamping progressive tools and metal fabrication/ precision stamping parts for the automotive, home appliance and motor rotor stator for more than 20 years.

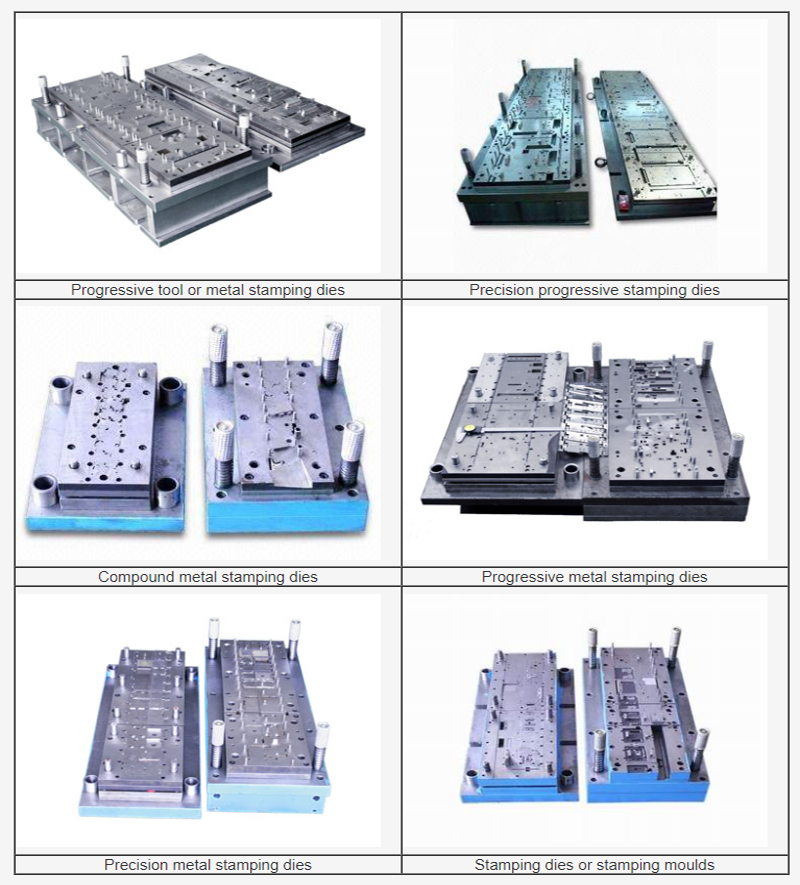

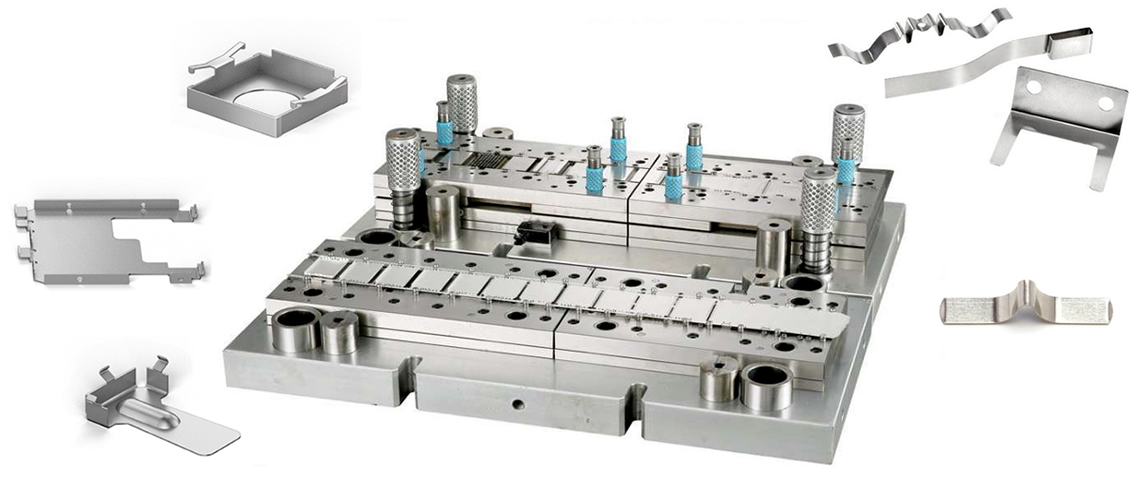

We design and build different kinds of metal stamping dies or stamping tools for you custom stamping parts or stamped parts. Such as Line dies, Blanking dies, bending dies, forming dies, Drawing dies, coining dies,compound dies, progressive dies or progressive tool. In some countries, stamping dies may be also called stamping molds or stamping moulds. No matter how it called, you can get what you need.

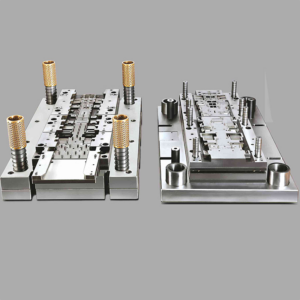

Our precision stage steel metal stamping tools and metal stamping progressive tools make your productivity, quality, design and economy as our important consideration. We can design and manufacture the simple or complex stamping dies or moulds fitting your exact applications.

Mian Features:

- Mould Material: cr12, cr12mov, Dc 53, SKH-9, 45#

- Stamping Material: stainless steel, aluminum alloy, brass, zinc, carbon steel, copper etc.

- Tolerance: ±0.03mm

- Software: 2/3 D, Auto CAD, CAE, PRO-E, Solidworks, UG, Catia, MOLDFLOW, ANYCASTING

- Surface: TD coating, heater treatment, polish etc

- Package: wooden case

- Certification: ISO9001, SGS

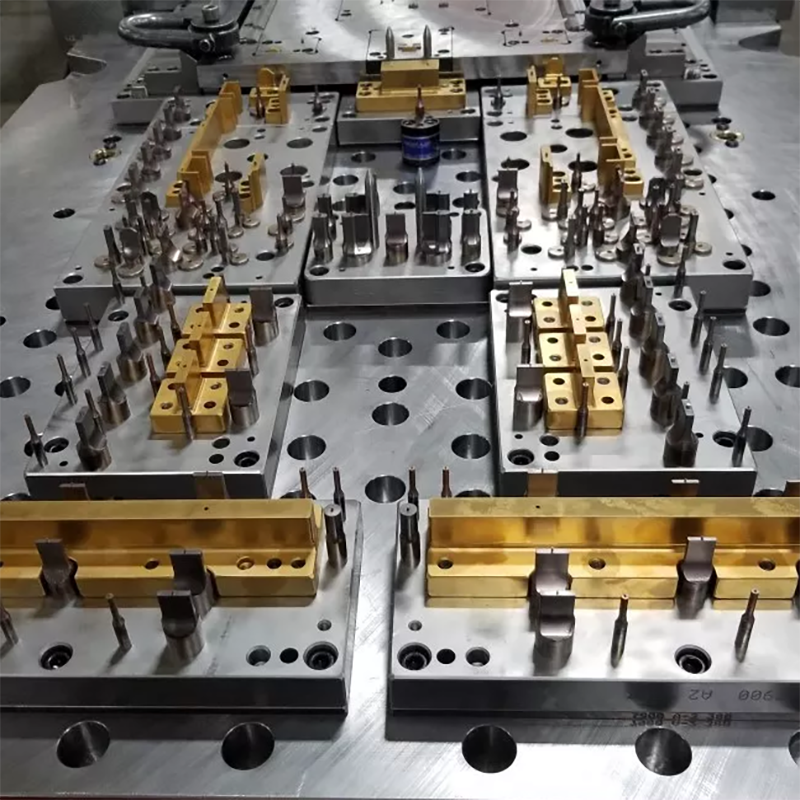

We have CNC machine center, CNC wire cutting machine, quality testing equipment, etc. Mainly focus on metal stamping mold and its automation equipment, started from mold design, processing and assembly, debugging, manufacture to the stamping automation equipment’s full process. Also we have deeply technical reserves which can effectively solve the industry difficulties and provide the One-stop Service for customer.

Mould Design Capacity

- Sheet metal finite element analysis capability;3D and 2D design capability;

- 5 mould design engineers;

- 20 years mould design experience;

- 15~30 days fast mould delivery;

- Mold manufacturing capacity: 50set/Mouth;

Stamping Capacity

- 63T~800TPunching machine;

- Product minimum size to 0.1 mm,maximum size to 5mm processing capacity;

- Power Press Type: High Speed /Normal Stamping Power

- Material: Steel, Stainless steel, SGCC, Steel Plate Cold Commercial,Q325 etc;

- Stamping capacity: 200,000 shot/Month;

Quality Control Capacity

- 8 person Full-time quality control personnel;

- Mitoyo three coordinate measuringinstrument, Keyence height 3D profilometer,other high-precision measuring equipment;

- IS9002 quality management system certification;

- With PDCA and 5W1H good work habits;

- Inspection report and SGS report areprovided for each product

Main Tooling Manufacturing Machines

| Machinery | Quantity |

| High speed of 42000 and precision CNC | 2 |

| Other 7 CNC Machines | 7 |

| Makino Sinker EDM | 4 |

| Sodic Wire EDM | 5 |

| High Precision Grinder | 5 |

Technology

Laser Cutting,MetalStamping,Sheet Metal Forming, Turning,Wire EDM,Welding Drawing Die;

Surface Treatment

Plating,Nitriding,TD,PVD

Complementary Services

- Design and Engineering

- 3D Printing

- Large-Scale 3D Metal Printing

- CNC Machiningy

- Fabrication and Welding

- Assembly and Finishing

- Inspection and Testing