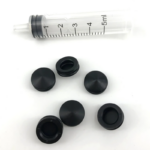

Pharma prefilled syringe plungers, also known as syringe pistons, are critical components in prefilled syringes designed for pharmaceutical applications.

Product Specifications

Silicone Plunger & Lip Seal is used in reciprocating seal devices, which has a longer life span than Silicone Rubber O ring.

Silicone Plunger & Lip Seal Working speed ranges vary in different materials

| Working pressure | < 25 MPa |

| Working temperature | -40~+120℃ |

| Medium | hydraulic oil, water, air |

| NBR | 0.01~0.6 m/s |

| FKM | 0.05~0.3 m/s |

| PU rubber | 0.01~1 m/s |

| Lip ring made of PU rubber is better in sealing, life span and working pressure limit without retain ring. |

Silicone Plunger is made from high grade silicone, liquid silicone rubber ( LSR ) because it is better in sealing, life span and working pressure limit without retain ring compared with other rubber plungers seal, which are mainly made of NBR or PU rubber.

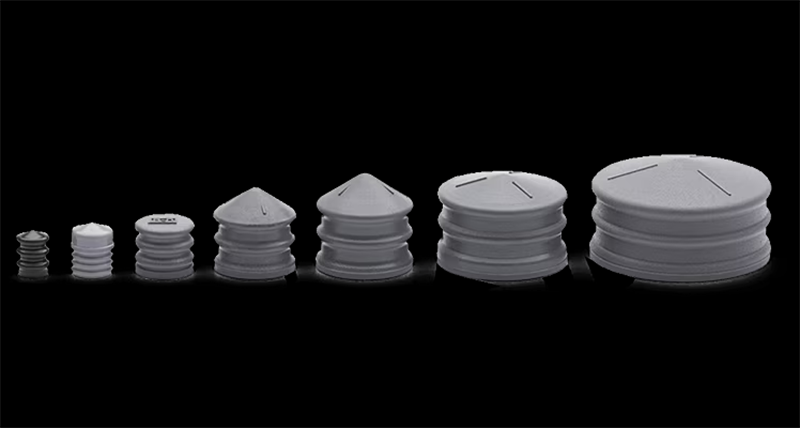

Silicone Plunger & Lip Seal is mainly made by silicone rubber compression mold tooling or LSR injection molding ( LIM ) with middle mold plates.

Silicone Plunger Seal ‘s margin & edge should not have silicone rubber flashing ( burrs ) because it will rotate when device is working. For sealing function, silicone plunger seal ‘s design and sizes telorance have higher demands, especially for seal edge.

Middle mold plates are chamfer processed by cutting tool, which will wear out with processing. In aim for deserved silicone plunger seal ‘s designs and sizes, the cutting tool needs to be changed frequently after a short-time processing.

Silicone Plunger & Lip Seal properties:

- Excellent sealing

- Less friction and smooth movement

- Good pressure resistance and wide applicable pressure range

- Simple structure and low cost

- Easy installation