Overview:

Compression-molded high-temperature resistance silicone oven mitts are premium kitchen and industrial safety accessories crafted from FDA/LFGB-compliant food-grade silicone using advanced compression molding technology. These durable, heat-resistant mitts (withstanding up to 500°F/260°C) are designed for safe handling of hot surfaces in kitchens, laboratories, manufacturing, and automotive settings. Our products meet stringent safety and environmental standards, including RoHS certification. We offer comprehensive OEM services, from custom design to bulk production and packaging, ensuring tailored solutions for your brand. Experience one-stop reliability—contact us to discuss your project needs today.

Characteristics:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Lead Time | 20–35 days |

| MOQ | Small order accepted |

| Size | Custom |

| Sample | Available |

| Function | Pot holder, heat resistant |

| Package | Custom packaging available |

| Logo | Customized logo accepted |

| Colors | Black, gray, red, or customized |

| Advantage | Eco-friendly, natural, healthy |

| Quality Certifications | ISO9001, SGS |

Advantages of Products:

- Superior Heat Resistance

Ensures optimal protection against high temperatures, preventing burns during oven use.

- Durability and Longevity

Made from high-quality silicone, offering long-lasting performance with minimal wear and tear.

- Eco-Friendly and Safe

Manufactured using food-grade, non-toxic silicone, ensuring safety for both users and the environment.

- Customizable Design

Flexible molding options allow for custom sizes, colors, and branding to meet client specifications.

Production Process:

- Material Selection

– High-quality, food-grade silicone rubber is selected for its heat resistance, flexibility, and durability.

– The silicone is often tested for compliance with industry standards for safety and performance.

- Mold Design and Preparation

– Customized molds are designed based on the specific requirements of the oven mitts (e.g., size, shape, and texture).

– Molds are cleaned and prepared for the compression molding process to ensure precision and consistency.

- Compression Molding Process

– The silicone material is pre-measured and placed into the mold cavity.

– The mold is then closed under high pressure and heated, allowing the silicone to cure and take the shape of the mitt.

– This step ensures that the mitts have the necessary thickness, strength, and heat resistance.

- Cooling and Demolding

– After the curing process, the molded silicone is allowed to cool and solidify.

– Once cooled, the mitts are carefully removed from the mold, ensuring no deformation or damage to the product.

- Post-Processing and Quality Control

– The oven mitts undergo post-processing, including trimming excess silicone material (flash) and refining edges to ensure a smooth, clean finish.

– Quality control checks are performed to ensure the mitts meet safety standards, including heat resistance, durability, and functional design.

- Customization and Final Inspection

– Any custom branding, logos, or additional features (e.g., textured surfaces for better grip) are added at this stage.

– The final product undergoes thorough inspection to ensure it meets both aesthetic and functional requirements.

- Packaging

– Once approved, the oven mitts are carefully packaged for shipping, ensuring that each mitt remains in perfect condition during transit.

– Custom packaging options are available based on customer requirements.

This process ensures that OEM compression-molded silicone oven mitts are of the highest quality, offering optimal heat resistance and reliability for kitchen use.

Why Choose Us?

- Certified Quality and Industry Standards

Our factory is ISO 14001, ISO 9001, ISO 13485, and IATF 16949 certified, ensuring the highest standards in producing silicone kitchenware.

- Comprehensive Customization Solutions

With six self-built factories and multiple production lines, we provide flexible, efficient manufacturing for silicone kitchenware, tailored to your specific needs.

- Rigorous Quality Control

Our professional testing laboratory and quality control department ensure that all silicone kitchenware undergoes strict testing before shipment for superior quality.

- Expert Engineering and Customer Service

Our experienced design and sales teams offer innovative solutions and responsive service, guiding you through the entire process from design to delivery.

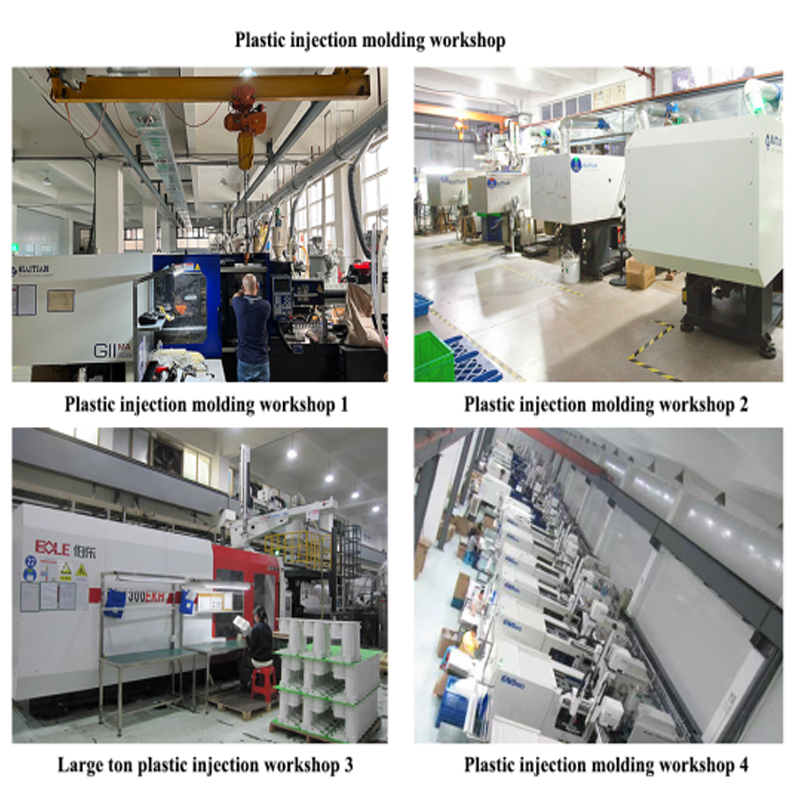

Factory Show:

Our cutting-edge facility features advanced mold-making technologies such as CNC machining, Mirror EDM, EDM, and Slow-Speed Wire Cut (WC) for precise, efficient production. We operate with 15 rubber compression machines and 2 Liquid Silicone Rubber (LSR) injection molding machines, specializing in overmolding techniques.

To ensure top-tier quality, we use 3D projectors, sealing testers, elasticity measurement instruments, and durometers, supported by a dedicated Quality Control (QC) team that conducts thorough inspections throughout production.

Additionally, our facility is equipped with AutoDryer Lines, automatic screen printing machines, 3D measuring systems, high-speed doming machines, and extra CNC equipment, ensuring consistency, precision, and exceptional quality in every product.