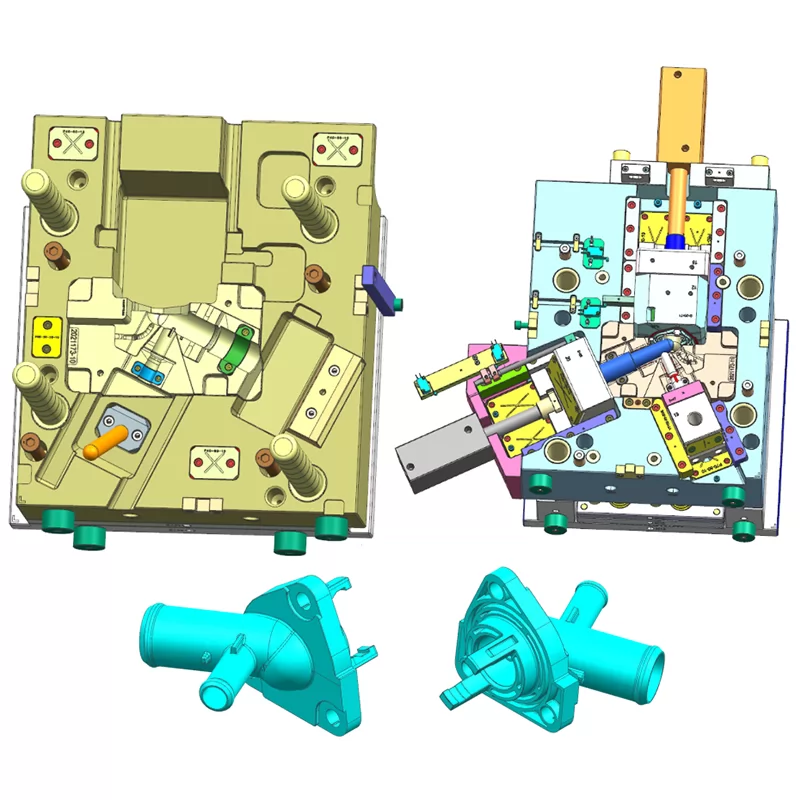

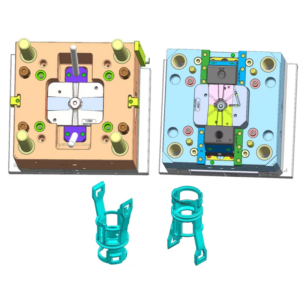

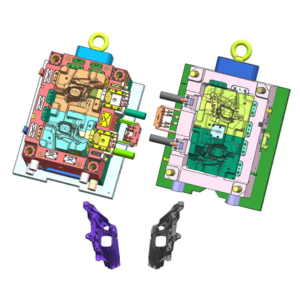

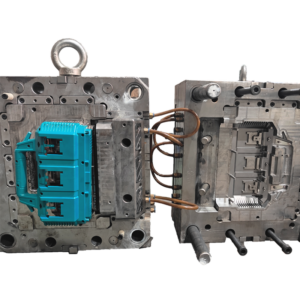

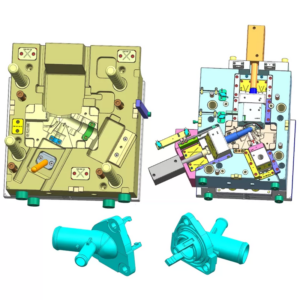

Custom New Energy Vehicle Plastic Housing Injection Mould

We offer custom new energy vehicle plastic housing injection molds and comprehensive services to clients in the new energy vehicle industry. Our service including:

Mold Design and Engineering Support

Material Selection and Recommendations

Mold Manufacturing

Prototype Development

Mold Trial and Adjustment

Rapid Delivery

Quality Assurance

Sustainability Practices

Types of Tooling

1.Prototype Tooling

Prototype tooling, also known as soft tooling or rapid tooling, is when tools are designed, produced, and tested for fit, form, and function in preparation for the production process. During the prototyping process, manufacturers can adjust the design several times to achieve optimal performance and finish. Some materials that are often used in prototyping are silicone rubber, aluminum alloy, and soft steel due to their lower cost; they are typically faster and easier to shape. The benefits of prototype tooling include:

- Creates prototypes fast, often taking just hours or days rather than several weeks.

- Smaller Investment, allowing test runs to check for design flaws, tolerances, and more.

- Accurate parts can be produced

2.Production Tooling

Prototype tooling, also called soft tooling or rapid tooling, allows manufacturers to design, produce, and test tools to assess fit, form, and function before full-scale production. Materials like silicone rubber, aluminum alloy, and soft steel are commonly used for their cost-effectiveness and ease of shaping. The benefits include rapid production of prototypes in hours or days, lower investment costs, and the ability to produce accurate parts for testing and validation.

Mould Making Process

- Product3D checking and DFM

- Tooling design and get approval

- Mold material purchase

- Bold building of CNC and EDM process,

- Auxiliary machining such as wire EDM, drilling and grinding

- Polishing

- Mold assembly

- Quality Control

- T0 and P0 sample for customer approval

- Packing and delivery

Tight Tolerances

Using wire EDM, 5-axis CNC and other high-precision equipment to achieve tolerances as 0.01mm.

Main Tooling Manufacturing Machines

| Machinery | Quantity |

| High speed of 42000 and precision CNC | 2 |

| Other 7 CNC Machines | 7 |

| Makino Sinker EDM | 4 |

| Sodic Wire EDM | 5 |

| High Precision Grinder | 5 |

Materials

- P20 (P20HH)

- S136 (S136H)

- NAK80

- H13

- 718 (718H)

- 2738 (P20+Ni)

- 2316

- MoldMAX

- Aluminum

Why Choose Us for Tooling Manufacturing?

1.Advanced Equipment and Technology

We possess advanced manufacturing equipment and technology, including high-precision CNC machines, CAD/CAM software, and 3D printing technology. These advanced toolings enable us to achieve precise manufacturing of tooling and accomplish intricate details and complex shapes with utmost accuracy.

2.Customized Design and Engineering Support

We work closely with our customers, gaining in-depth understanding of their needs and product requirements. Our experienced team of engineers provides professional design advice and engineering support, ensuring that the tooling design meets customer expectations and specific product requirements.

3.High-quality Materials and Manufacturing Standards

We strictly select high-quality materials for our tooling, such as premium-grade steel and wear-resistant alloys. Additionally, we adhere to strict quality control standards and processes to ensure the manufacturing quality and consistency of each tooling. This contributes to improved durability, stability, and lifespan of the tooling.

4.Technological Innovation and Continuous Improvement

As an innovation-driven and continuously improving factory, we constantly pursue technological innovation, exploring new manufacturing methods and materials. By incorporating advanced processes and technologies, we enhance the precision, complexity, and production efficiency of our tooling to meet the ever-evolving market demands.