The plastic parts assembly for new energy vehicle batteries that we manufacture is highly complex and designed to support the stability and performance of electric vehicle battery systems. The key features of these components are as follows:

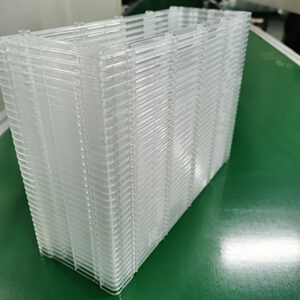

- High-Strength Materials: We use high-performance engineering plastics, such as polymer composites, to ensure that the components possess sufficient strength to withstand the weight and vibrations of the battery modules.

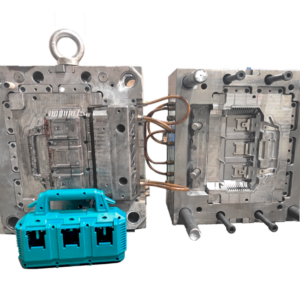

- Precision Manufacturing: These components are manufactured using high-precision injection molding processes to ensure that each component is precise in dimensions and shape to meet the requirements of the battery modules.

- Sealing Performance: The design of battery plastic parts takes into account sealing performance to ensure that the battery system is protected from external elements, ensuring its long-term stability.

- High-Temperature Stability: These components must be able to operate in high-temperature environments, so they utilize high-temperature-resistant materials to ensure they do not fail during battery operation.

- Flame Retardant Properties: Battery plastic parts have flame-retardant properties to reduce the risk of fires and ensure the safety of the battery system.

- Customized Design: Based on the specific design requirements of different battery modules, we offer customized design and manufacturing to meet the specifications of various new energy vehicle battery systems.

These battery plastic parts assemblies play a critical role in new energy vehicle battery systems, ensuring their performance, stability, and safety, thereby advancing the development of clean energy transportation.

Our exceptional technical expertise and capabilities in producing the New Energy Vehicle Battery Plastic Parts Assembly are evident in the following areas:

- Highly Engineered Design: We boast a highly specialized engineering design team with profound knowledge of battery systems, capable of providing custom designs for battery plastic components to meet the intricacies and performance requirements of new energy vehicle battery systems.

- Material Expertise: We have specialized knowledge in material selection, understanding the characteristics of various high-performance engineering plastics and composite materials to ensure material choices align with high-temperature, high-strength, and flame-retardant requirements.

- Advanced Injection Molding Technology: We employ high-precision injection molding technology to ensure each component’s dimensions and shapes are precise, meeting the demands of battery systems. We also utilize two-shot molding technology to integrate multiple materials or colors, enhancing component functionality.

- Precision Manufacturing: Our manufacturing processes are finely tuned to ensure each component exhibits high precision and consistency, accommodating various specifications and requirements of different battery modules.

- Quality Control: We implement stringent quality control, including dimension measurements, visual inspections, and performance testing, to ensure each component complies with high-quality standards.

- Continuous Improvement: We continually enhance our manufacturing processes, adopting the latest technologies and best practices to adapt to market and customer demand changes, ensuring consistent performance improvements in our products.

This professional expertise in technology and capabilities enables us to provide high-quality, high-performance plastic component assemblies for new energy vehicle battery systems, meeting the stringent requirements of battery systems and advancing the development of clean energy vehicles.