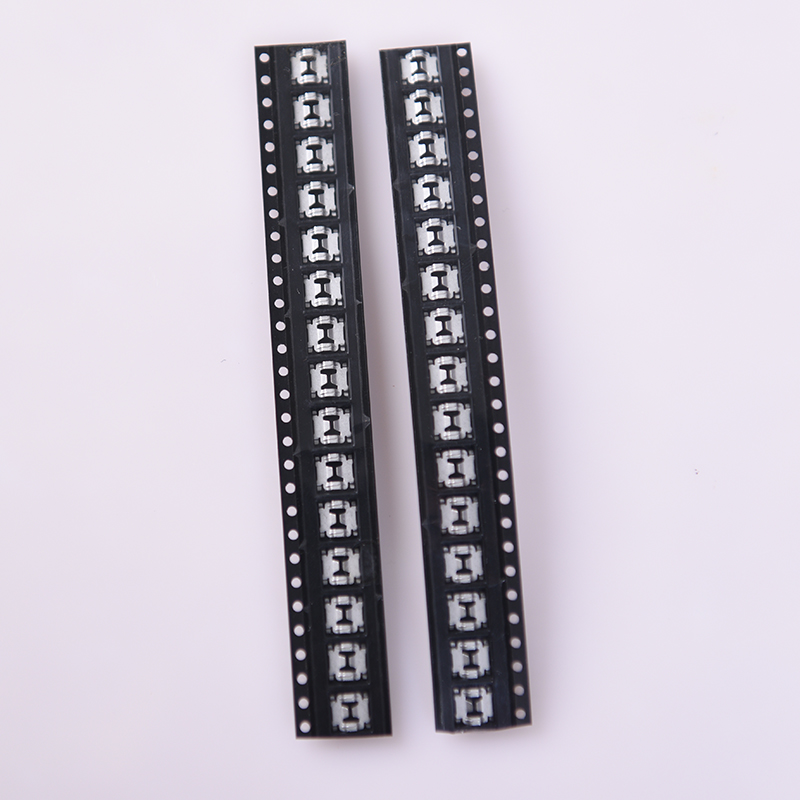

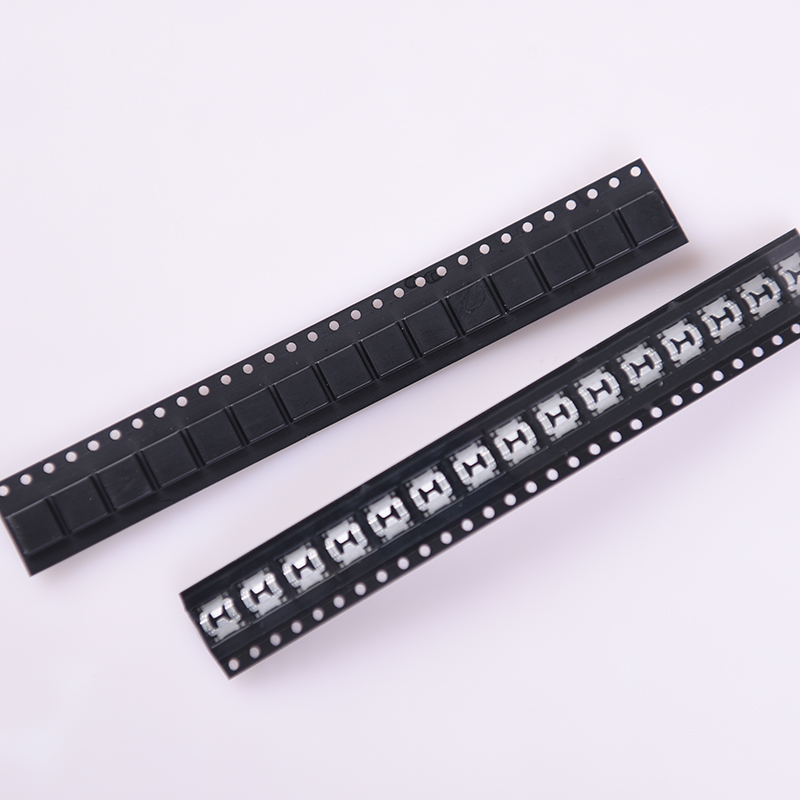

Metal Stamping Electronic Shrapnel Parts for PCB Board LED Circuit Board Shrapnel Hardware

We produce all kinds of hardware fittings, like CLIP, METAL CLIP, CLASP, BUCKLE, SHRAPNEL, BATTERY SHRAPNEL and so on. We also provide professional CUSTOMIZED SERVICE for the STAMPING PARTS, from money clips, belt clips to fasteners in various materials and surface treatments. We have more than 20-year experience in professional hardware stamping parts manufacturing.

YJC Is A Dedicated Manufacturer Specializing in Precision Metal Stamping Die Production.

Our core expertise lies in the design and fabrication of punching dies, with a focus on:

- Punching Die Design and Manufacturing for Household Appliances

- Punching Die Fabrication for LED Light Shields

- Precision Punching Dies for the Electronics Industry

In addition to our proficiency in these areas, we provide comprehensive solutions to our customers, backed by our sales, R&D, mold and parts departments. By seamlessly integrating precision die stamping, hardware components, and assembly processes, we consistently deliver turnkey solutions tailored to our clients’ needs.

Our company is equipped with state-of-the-art facilities capable of handling large-scale mold machining and extensive parts forming, further bolstering our commitment to precision and quality.

Why Choose YJC?

1. Premium Material

2. Hight precision. The precision can reach 1-4μm,Ra 2μm.

3. Rational design. Accurate layout is good for produce and saving the product’s raw material.

4. Rational construction , easy accessibility. Good for maintenance and repair

5. Reasonable arrangement of technology

6. Right Heat treatment

7. Best suitable parts clearance

8. Standard component choose famous brand.

9. Strict QC quantity control .

10. Timely delivery and best service

Our Factory