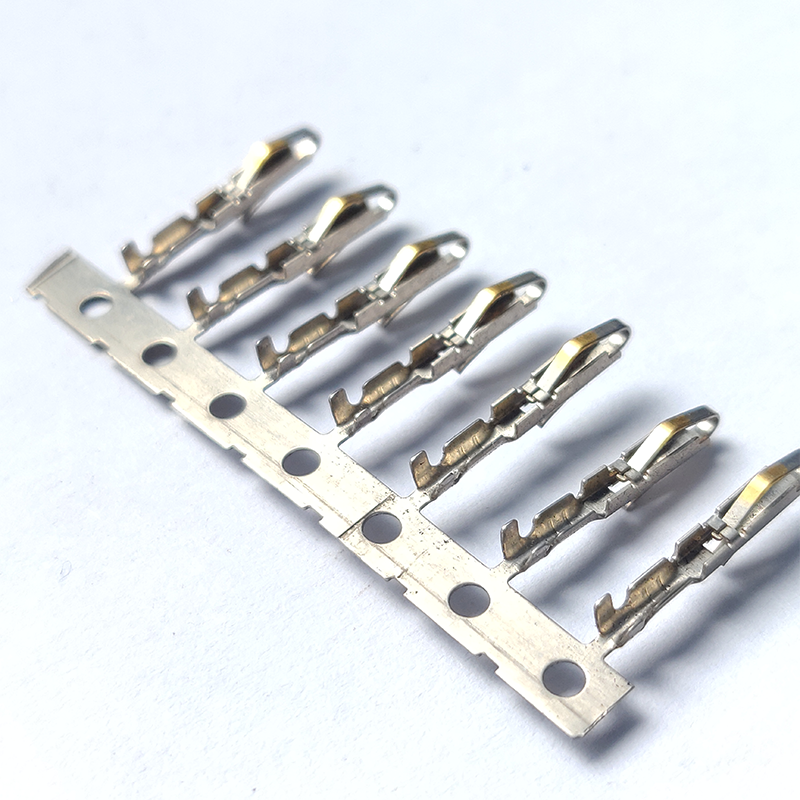

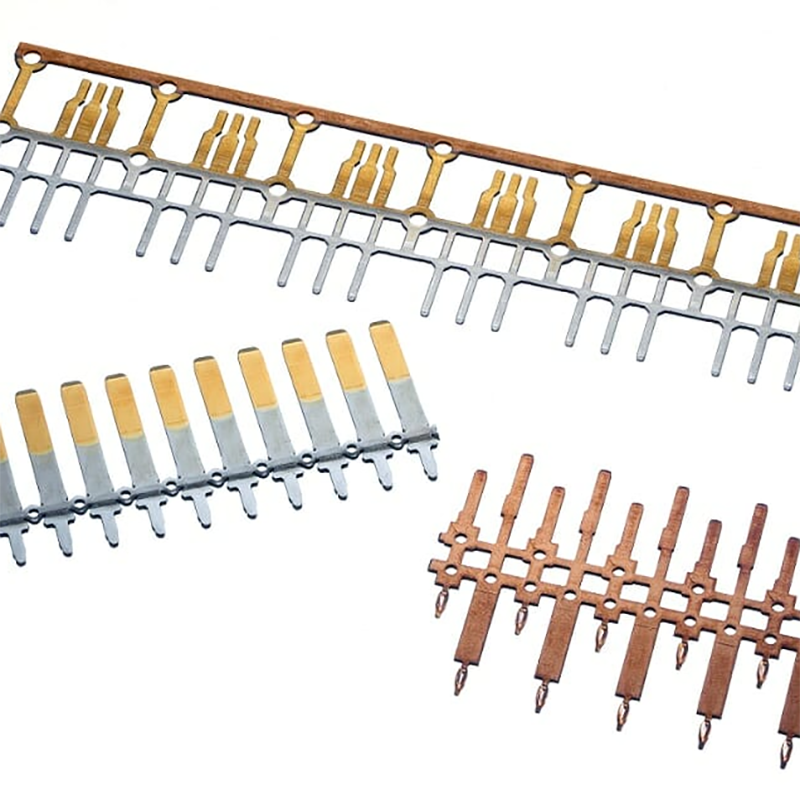

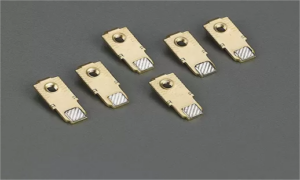

Metal Stamping Contacts Sheet Staming Strip Custom Contacts

The advantages of our company in producing Metal Stamping Contacts include a highly precise manufacturing process, large-scale production capability, cost-effectiveness, high customization, stringent quality control, prompt delivery, and environmentally sustainable production methods. These factors make YJC’s Metal Stamping Contacts a reliable electrical connecting component widely used in various applications.

Advantages of Metal Stamping Contacts:

- Cost-effective.

- Highly precise.

- Durable and reliable.

- Excellent electrical conductivity.

- Customizable.

- Easily automated for production.

- Environmentally friendly due to recyclability.

Material

We routinely stamp parts made from the following materials:

- Gold alloys

- Platinum alloys

- Palladium alloys

- Silver alloys

- Bi-metallic materials

- Niobium, Titanium

- Copper alloys

- Inconel

- Monel

- Stainless steels

Our Metal Stamping Contacts find applications in a variety of industries and situations due to their versatility, durability, and precision. Some common applications include:

- Electronics:mobile phones, computers, and consumer electronics to establish reliable electrical connections within circuits and connectors.

- Automotive: airbags, ignition systems, sensors, and lighting, ensuring dependable electrical connections in vehicles.

- Appliances: refrigerators, washing machines, and ovens, ensuring proper electrical connections for the functioning of these devices.

- Aerospace: communication equipment, and control systems.

- Medical Devices: pacemakers, infusion pumps, and diagnostic equipment.

- Telecommunications: routers, switches, and communication systems, to maintain consistent and high-quality connections.

- Power Distribution: in power distribution systems, they assist in the efficient flow of electricity, reducing energy loss and minimizing heat generation.

- Renewable Energy: solar panels and wind turbines to connect various components and ensure reliable energy production.

- Industrial Machinery: CNC machines, robotics, and manufacturing equipment, where consistent electrical connections are essential for operations.

- Transportation: trains and trams, ensuring safe and efficient electrical connections for signaling and control systems.

- Military and Defense: communication devices, radar systems, and military vehicles.

- Marine: They find use in marine equipment and vessels, ensuring reliable electrical connections for navigation, communication, and control systems.

- Energy Storage: batteries and capacitors, they help maintain efficient electrical connections, enabling energy storage and release.

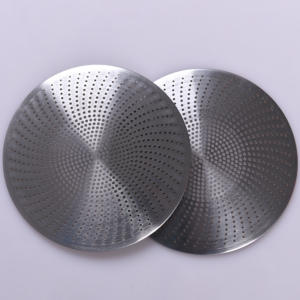

Our Factory