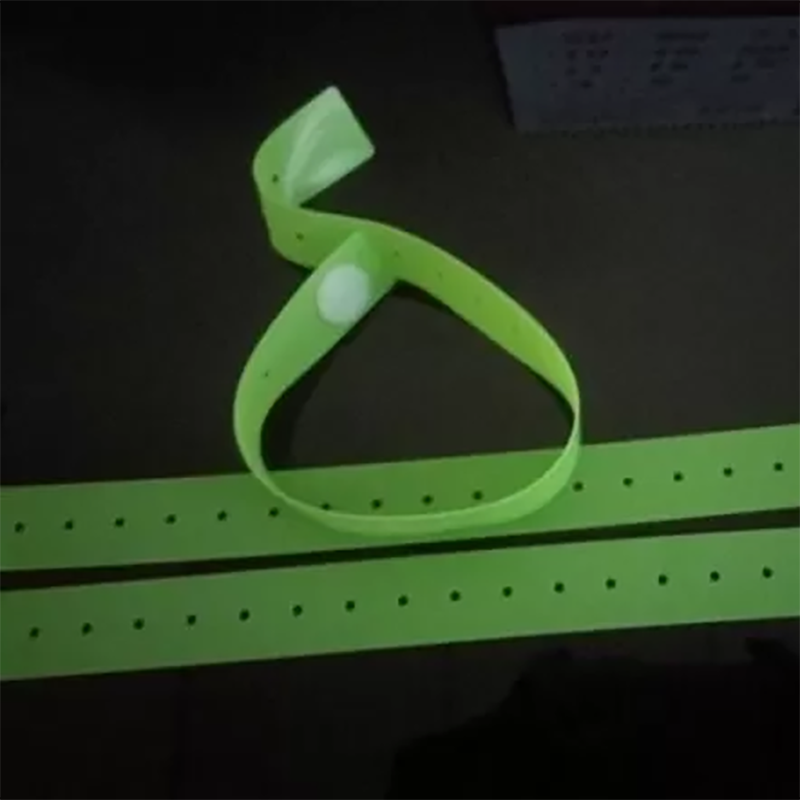

Medical Grade Disposable Elastic Silicone Tourniquet

Disposable Tourniquet is a bandage, used to control venous and arterial circulation to an extremity for a period of time

The tourniquet is usually applied when the patient is in a life-threatening state as a result of continuous bleeding.

New hemostatic technologies are being developed. Various hemostatic agents, sealants and adhesives have been developed, but better methods of stopping bleeding are still being developed.In an emergency, surgical or battlefield situation, a tourniquet is still an essential, quick and effective way to reduce uncontrolled bleeding.

Our advantages:

1. Possess precision mold manufacturing technology (since 1998)

2. Complete production and manufacturing equipment and testing equipment.

3. Professional QC team controls product quality to ensure the quality of ex-factory products.

4. Flexible customization according to customer requirements.

5. Five senior engineers: provide technical/production/design/art support, etc.

6. The factory has obtained ISO9001 international quality management system certification and production process specifications.

7. Purification of the production environment can ensure that silicone products meet food and medical grade standards.

8. The sales and service team is responsible for rapid quotation and sample delivery to meet customers’ rapid response requirements.

6. Five factories: mold manufacturing, silicone rubber compression, injection molding, LSR injection molding and assembly plants.

7. Mold manufacturing equipment: CNC, mirror edM, EDM, low speed wire cutting and other auxiliary equipment.

8. Testing equipment :3D projector, sealability tester, elasticity tester, hardness tester, etc.

10. Dust-free environment :LSR injection molding machine, 3 rubber compressors, 100,000 rated dust-free factory assembly lines.

11. Quick response organization: support customers in a short time

Quickly Quotation Demands:

1. 2D/3D designs Drawings, Samples, or other basic information

2. Materials Demands:

3. Surface Demands.

4. Sizes Tolerance Demands: +/-0.005mm – +/-0.3mm