Overview

The Medical Liquid Silicone Rubber Duckbill Check Valve is a specialized non-return valve designed to prevent backflow. Its one-way mechanism opens to allow the flow of fluids such as liquid, water, air, and gas when the opening or cracking pressure is increased. These valves are essential in various applications, particularly in medical devices, due to their reliability and precision in controlling flow.

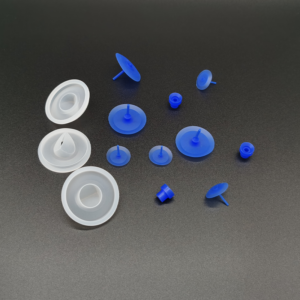

Types of Duckbill Check Valves

Duckbill Check Valve:

This valve features a duckbill-shaped design, functioning as a one-way check valve that prevents backflow. It opens in response to an increase in pressure, allowing the fluid to pass through while maintaining a seal to prevent reverse flow. These valves are commonly used in medical devices, drainage systems, and other applications requiring precise flow control.

One-Way Umbrella Valve:

The umbrella valve is an elastomeric valve gasket with a diaphragm-shaped sealing disk or an umbrella-like structure. It is designed to open and close with minimal air pressure, with its performance influenced by factors such as material modulus, effective flow area, preload on the sealing edge, and the thickness of the umbrella skirt section. These valves can be customized in shape, size, and material to meet specific requirements.

Applications of Duckbill Check Valves

Medical Check Valves:

These valves are used in various medical devices, including ventilators, respiratory equipment, manual resuscitators, CPR masks, anesthesia apparatus, and surgical equipment. They ensure one-way flow in breathing systems, enhancing safety and efficiency in medical procedures.

Breast Pump Valves:

Duckbill check valves are commonly used in breast pumps, such as those by Ameda, Medela, and Spectra. They function as seals, controlling air and liquid flow, and serving as nipple nozzles. These valves are produced using liquid silicone rubber injection molding (LIM), ensuring high precision and reliability.

Drainage System Valves:

In waste water systems, sewage pools, and drainage systems, duckbill check valves are used to control the flow of liquids. They prevent backflow and maintain efficient drainage, making them crucial components in managing waste water and preventing contamination.

Why Choose Our Duckbill Check Valves?

- Extensive Experience:With decades of experience in precision silicone rubber molding production, we offer expertise and high-quality products tailored to meet specific requirements.

- Customization:We provide precise designs and sizes for silicone rubber valves, supporting your devices according to your 3D/2D drawings, samples, and flow parameters.

- State-of-the-Art Facilities:Our dust-free silicone rubber compression molding plants and dismantling plants ensure a clean production environment, meeting the highest standards of quality and hygiene.

- Clean Room Production:Most silicone medical parts are produced and finished in clean rooms, with dust-free plants achieving up to a 100,000-stage cleanliness level, ensuring product safety and reliability.