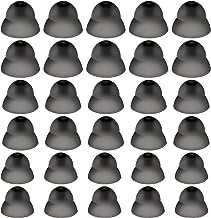

One-stop Solution Manufacturer for Hearing Aids Parts

We are a perfect provider for LSR overmolding hearing aids parts by using the over-molding process for our customers.Our advanced production capabilities, outstanding quality and two decades of experience with liquid silicone rubber (LSR) components make us an ideal partner for your project.

Working with YJC, an experienced expert in LSR/Silicone/Plastic and manufacturing technologies, ensures you’ll not only get exceptional care and reliability, you’ll also get the best solution to meet your specific production needs.

Why Is LSR a Good Material for Hearing Aids Components?

1.Biocompatibility&Hypoallergenic

Any item that requires close contact with the body for an extended period of time, such as hearing products, needs to be biocompatible and hypoallergenic. LSR is a common material used to make these types of products because it has these properties.

2.Comfort

LSR has a soft, smooth texture that makes it pleasant to the touch. Due to its softness and flexibility, it will conform to the shape of the ear, providing a comfortable experience for the user. It will not cause skin reactions or irritation and is comfortable enough even for prolonged use.

3.Chemical Stability

Products for use in the ear should be clean and safe. An important factor in LSR’s good biocompatibility is its chemical stability. Silicone rubber is a chemically inert product, so it is not adversely affected by sweat and other environmental or cleaning substances during use.

4.Design Flexibility

LSR is very versatile and can render complex shapes, including those with complex designs, thin walls, undercuts, and is also suitable for small parts.

5.High Precision

LSR material can be used for precise mold injection molding, ensuring the creation of very accurate hearing aid casings to ensure a perfect fit with internal electronic components.