What is the difference between Insert Molding and Overmolding techniques? Below we will reveal and discuss these two terms together.

Molding Mastery:

In the intricate world of manufacturing, Insert Molding and Overmolding stand out as integral processes within the broader scope of Injection Molding. These techniques, while often mentioned interchangeably, boast distinct methodologies and applications, contributing to the creation of complex and revolutionary products.

The Core Process:

Injection Molding initiates with the introduction of raw thermoplastic resin into a hopper, followed by heating to temperatures between 300° to 650° Fahrenheit to induce melting. Once molten, the resin undergoes pressurization before being injected into a robust steel mold.

Understanding Materials:

Diving deeper, it’s crucial to distinguish between thermoplastic and thermoset materials. Thermoplastics, like those utilized in our processes, can be reheated repeatedly, offering versatility in manufacturing. Conversely, thermosets, once cured, cannot be reheated, presenting distinct challenges in molding processes.

The Mold Dynamics:

Molds used in Insert Molding and Overmolding are crafted with precision, comprising steel plates, water lines, and ejection pins. Simplified open-shut molds facilitate these processes, ensuring seamless integration of inserts or additional materials into the final product.

Insert Molding Insights:

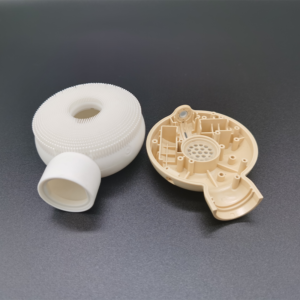

Insert Molding, a precision-driven technique, involves encasing preformed metal or other components with molten thermoplastic resin. This process aims to create a unified, seamless unit, ideal for applications such as manufacturing rods, electrical harnesses, or threaded components.

Overmolding Unveiled:

Overmolding, also known as Two-Shot Molding, elevates complexity by integrating two distinct materials into a single molded product. This process, often utilized in cable overmolding or micro molding, showcases the innovative synergy of materials in manufacturing.

Advantages Galore:

Both Insert Molding and Overmolding offer unparalleled benefits, including reduced labor costs, enhanced design flexibility, and superior quality control. These techniques empower manufacturers to produce lightweight, compact, and durable components with utmost efficiency.

Mold Matters:

Central to both processes are meticulously designed molds, guiding the plastic during manufacturing. Mold cavity design, alignment tools, and pin configurations play critical roles in ensuring optimal product quality and structural integrity.

Navigating Terminology:

While the terminology surrounding these techniques may vary, clarity and understanding remain paramount in the manufacturing landscape. By embracing clear communication and industry-standard terminology, professionals can navigate the intricacies of Insert Molding and Overmolding with ease.

Innovation Unleashed:

Insert Molding and Overmolding, while distinct in approach, share a common goal of molding plastic around existing components to create innovative products. These versatile techniques drive advancements in durability, aesthetics, and functionality, shaping the future of manufacturing.

Empowering Decision-Making:

Selecting the ideal molding process is a pivotal step in product development. Whether opting for Insert Molding’s precision integration or venturing into Overmolding’s material synergy, informed decision-making is key to manufacturing success.

LSR Overmolding Services

YJCPolymer stands out as a premier LSR overmolding manufacturer with over 20 years of experience in providing cost-effective solutions for precision overmolded components and assemblies in liquid silicone rubber (LSR) and plastic or metal.

At YJCPolymer, we stand ready to guide you through the intricate world of manufacturing, offering expertise and insight to bring your product vision to life. Join us on a journey of innovation and excellence, where every mold tells a story of transformation and possibility.