The art of injection molding has been refined over the years and has proven to be one of the most reliable and effective methods for producing precise, high-quality components. In the medical industry, this process plays a critical role in manufacturing medical devices, equipment, and consumables that require exact specifications and the highest standards of quality. With medical mold injection, customization is often required to meet unique design needs, and choosing the right manufacturer for this purpose is crucial to ensure the success of your project.

In this blog, we’ll discuss the essential factors you should consider when selecting a medical mold injection customization manufacturer, with a focus on the strengths and capabilities of YJC , a trusted leader in the industry. Here are the key principles to guide your decision-making process:

1. Ensure Regulatory Compliance

In the medical industry, regulatory compliance is not just a requirement—it’s a necessity. The medical device sector is governed by stringent regulations designed to ensure the safety, efficacy, and quality of products. These regulations include standards like ISO 9001(quality management for medical devices) and FDA certifications for medical devices.

When choosing a manufacturer, it’s crucial to ensure they are fully compliant with these standards. A reputable medical mold injection manufacturer should be able to provide documentation and certifications to verify their adherence to all relevant regulations. At YJC, we are proud of our robust quality assurance systems, with certifications including ISO 9001, ISO 13485, and FDA registration. We ensure that all products are designed, manufactured, and tested in compliance with the strictest regulatory standards, safeguarding patient health and ensuring product performance.

2. Experience and Expertise Matter

Experience and industry expertise are essential when selecting a medical mold injection customization manufacturer. Medical devices often require complex designs and precise tolerances that demand deep knowledge and a high level of expertise. Working with an experienced manufacturer reduces the likelihood of errors and ensures that the final product performs as intended.

YJC brings over two decades of experience in medical injection molding, specializing in custom mold designs for medical devices. Our team has a comprehensive understanding of medical-grade materials, industry-specific challenges, and best practices for creating components that are both functional and reliable. From initial design concepts to full-scale production, we provide end-to-end solutions backed by years of experience.

3. Review Past Samples and Case Studies

One of the most effective ways to evaluate a manufacturer is by reviewing their past work. Samples or case studies allow you to assess the manufacturer’s capabilities, quality consistency, and experience in creating products similar to yours.

At YJC, we offer access to a wide array of medical mold injection samples from past projects. Our portfolio includes custom injection molded parts for a variety of medical applications, from diagnostic devices to surgical instruments. We invite prospective clients to review these samples and assess the consistency and quality of our work. Our team is always available to discuss challenges we’ve overcome in the process and share how we can apply these lessons to your specific project.

4. Assess Manufacturing Capabilities

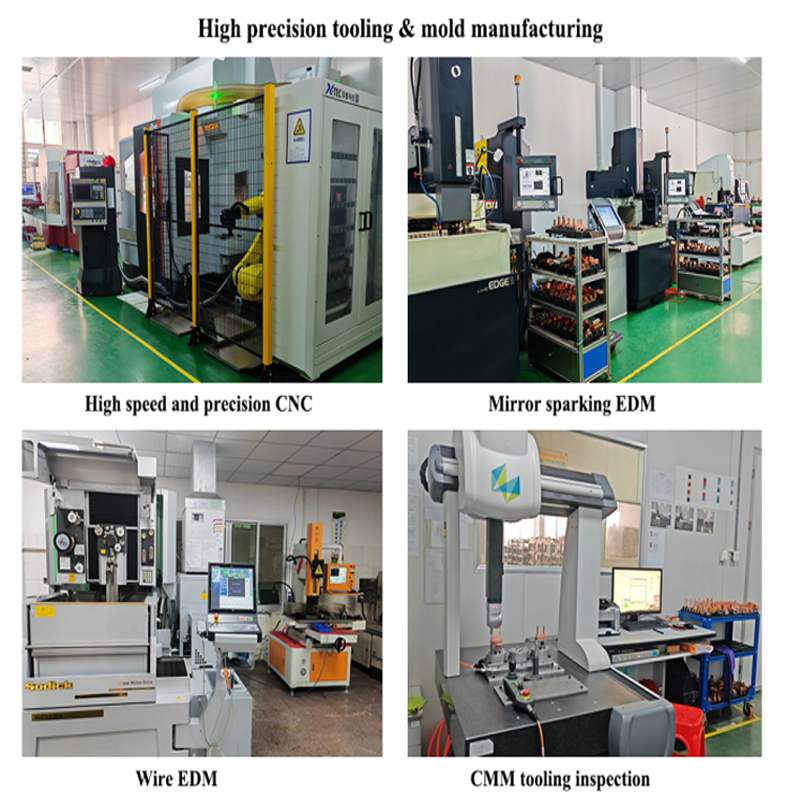

The production capabilities of a manufacturer can significantly impact your project timeline and quality. It’s essential to assess whether the manufacturer has the appropriate equipment, technologies, and skilled workforce to handle your project’s complexity, volume, and material requirements.

YJC stands out for its advanced manufacturing capabilities. We use state-of-the-art injection molding machines, CNC machining equipment, and automated systems to ensure precision, efficiency, and scalability. We also invest heavily in the latest mold design and engineering technologies, ensuring that we can deliver customized solutions tailored to your exact specifications. Whether you require high-volume production or intricate designs, we have the capacity to meet your needs.

5. Material Expertise and Compatibility

Material selection plays a crucial role in the performance, safety, and functionality of medical devices. Different applications require specific materials that can withstand harsh conditions, offer biocompatibility, or meet sterilization standards.

At YJC, we specialize in a wide range of medical-grade materials, including biocompatible plastics, high-performance polymers, and sterilizable materials. We understand the unique demands of medical applications and have extensive expertise in working with materials that meet stringent performance standards. Our team will help you select the best material for your project, ensuring optimal functionality and safety for your medical device.

6. Check References and Customer Feedback

References and feedback from previous clients can provide valuable insight into a manufacturer’s reliability, communication, and quality of work. By talking to past clients or reviewing online testimonials, you can gauge the level of customer satisfaction and the manufacturer’s ability to meet deadlines, maintain quality, and respond to issues.

YJC is proud of our strong reputation in the medical molding industry. Our clients often share positive feedback about our professionalism, reliability, and high-quality products. We encourage potential customers to reach out to us for testimonials or references from companies that have previously partnered with us for medical mold injection customization projects. Our transparent approach and dedication to customer satisfaction ensure we maintain long-term relationships with our clients.

7. Price Considerations

Cost is always a factor when choosing a manufacturer, but it’s essential to weigh it against quality and reliability. The lowest price doesn’t necessarily guarantee the best outcome, especially in the medical device industry where safety and performance are critical. Instead, focus on finding a manufacturer who offers the best value for your budget, with an emphasis on quality, experience, and customer support.

At YJC, we understand the importance of balancing cost with quality. We offer competitive pricing without compromising on the high standards required for medical products. Our transparent pricing structure ensures you’ll know exactly what to expect, with no hidden fees. We work closely with you to develop cost-effective solutions that align with your project’s needs.

8. Evaluate Communication and Collaboration

Effective communication and collaboration are essential for a successful partnership with a manufacturer. From initial design discussions to post-production support, clear and responsive communication ensures that issues are resolved quickly and that your project stays on track.

At YJC, we prioritize clear, open communication throughout every stage of the project. Our dedicated project managers keep you informed at every step, and our team is always available to answer questions or provide updates. We believe that close collaboration leads to better results, and we are committed to making sure your vision is fully realized.

Conclusion

Choosing the right medical mold injection customization manufacturer can be challenging, but focusing on key factors such as regulatory compliance, experience, manufacturing capabilities, and material expertise will help guide your decision. At YJC, we are dedicated to delivering high-quality, customized injection molding solutions for the medical industry. Our commitment to excellence, combined with our advanced technology and experienced team, ensures that we can bring your medical device ideas to life safely and efficiently.

If you’re ready to discuss your project or have any questions about our capabilities, we’d love to hear from you. Contact us today to learn more about how we can help turn your ideas into reality and provide the support you need every step of the way!