Hello, and welcome to this week’s blog! I’m Sunny from YJCPolymer, and today we’re diving into a process that’s at the heart of many product designs—overmoulding. If you’ve ever held a tool with a soft, ergonomic grip or marveled at a product that feels durable yet comfortable, chances are you’ve encountered overmoulding. In this blog, we’ll explore not only the overmoulding process but also the materials that make it all work.

At YJCPolymer, we specialize in delivering high-quality overmoulding solutions that enhance the functionality and aesthetics of your products. So, whether you’re in need of durable handles for tools or seeking a custom overmould that elevates the look and feel of your product, we’re here to guide you through the process of selecting the best materials.

What Is Overmoulding?

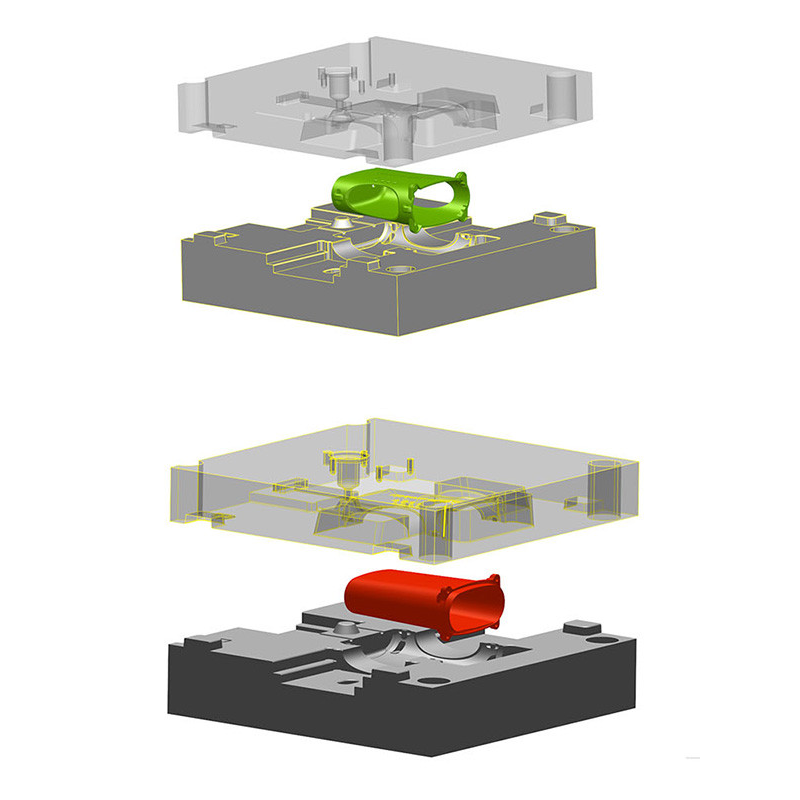

Before we dive into material choices, let’s quickly recap what overmoulding actually involves. Overmoulding is a manufacturing process where a layer of resin is molded over an existing base or substrate. This process is typically used to combine two or more materials in a way that enhances the performance of the product.

One of the most common reasons to use overmoulding is to improve the ergonomics of a product, such as adding a soft grip to a tool or device. Think of the last time you picked up a hammer, wrench, or even a camping flashlight—chances are, the part that you held was overmoulded to provide comfort and a secure grip. But the benefits of overmoulding extend beyond just comfort; it can also be used to improve aesthetics or combine different materials without the need for additional assembly methods like gluing or screwing.

The Importance of Material Selection in Overmoulding

Choosing the right materials for overmoulding is not as straightforward as it may seem. There are a variety of factors to consider, including compatibility between the substrate (the base material) and the overmoulding resin, as well as the specific function and aesthetics of the end product. Let’s break down the key considerations and the materials that work best for each application.

Substrate and Overmould Compatibility

The first rule in overmoulding is ensuring that the substrate and overmoulding materials are chemically compatible. The way the two materials interact will impact the final product’s durability, appearance, and overall performance. This is a critical step because materials that don’t bond properly could lead to poor adhesion, resulting in product failure over time. It’s also essential to consider factors like the melting temperature of both materials to avoid compromising the integrity of the substrate.

At YJCPolymer, we are experts in selecting and pairing substrates with overmoulding materials that deliver a seamless, durable finish. Whether you need a hard thermoplastic base with a soft elastomer or two thermoplastic components, we ensure optimal compatibility.

Soft Materials for Cushioning

One of the most common reasons to use overmoulding is for cushioning. If the goal is to create a squishy, shock-absorbing outer layer to protect a hard substrate, the overmoulding material needs to have a low flexural modulus. The flexural modulus is a measure of a material’s resistance to bending, and the lower the number, the softer and more absorbent the material will feel.

For cushioning applications, elastomers like Versaflex are ideal. These materials are soft, flexible, and provide excellent impact resistance. However, it’s important to keep in mind that for the cushioning to be effective, the overmoulding layer should be thick enough—at least 10 mils thick. Anything thinner may not provide the desired softness.

Grip and Texture

Another common reason to use overmoulding is to enhance the grip of a product. Think of tools, kitchen appliances, or even sports equipment. Overmoulding creates a non-slip surface that improves the user’s control over the product, even in wet or slippery conditions. For this application, materials with a high coefficient of friction are ideal.

Thermoplastic elastomers (TPEs) are commonly used for overmoulded grips. TPEs combine the flexibility and durability of rubber with the processing ease of plastics. TPEs are known for their excellent grip, even under extreme conditions, and they can withstand the wear and tear that comes with frequent handling.

Aesthetics and Customization

While functionality is paramount, aesthetics also play a significant role in many products. Overmoulding allows you to introduce color, texture, and even branding elements like logos and patterns to your product. The versatility of overmoulding materials means you can achieve the exact look and feel you’re aiming for, whether that’s a matte finish or a glossy, high-end appearance.

If you’re designing a product for consumers, don’t overlook the importance of making it visually appealing. At YJCPolymer, we offer a variety of color options and textures for overmoulding resins, making it easy to match your product with your brand identity. Whether you’re using overmoulding for a functional handle or a decorative feature, our team can help you select the right materials that enhance both form and function.

Bonding Considerations

Lastly, it’s important to think about how the overmoulding material will bond to the substrate. There are two main ways to achieve this: chemical bonding and mechanical bonding. Some materials chemically bond during the overmoulding process, while others rely on mechanical interlocking for a secure hold.

If you want the overmoulded grip to be replaceable, it’s best to choose materials that will not form a strong chemical bond. In contrast, if the overmoulded layer needs to stay permanently attached to the substrate, a chemical bond may be the better choice.

Conclusion

To wrap up, overmoulding is a versatile and valuable process that can enhance the functionality, appearance, and durability of your products. Selecting the right overmoulding materials is key to achieving the desired result, whether it’s for cushioning, grip, aesthetics, or product longevity. With thousands of material combinations available, it’s essential to work with a partner who understands the intricacies of material selection and can help guide you through the decision-making process.

At YJCPolymer, we specialize in providing high-quality overmoulding solutions tailored to your specific needs. Our expertise in material compatibility, customization options, and technical considerations ensures that we deliver the best possible outcome for every project.

Thanks for reading this week’s blog! If you have any questions about overmoulding or need advice on selecting the right materials for your project, don’t hesitate to reach out. We’re always happy to help and look forward to hearing from you. See you next week!