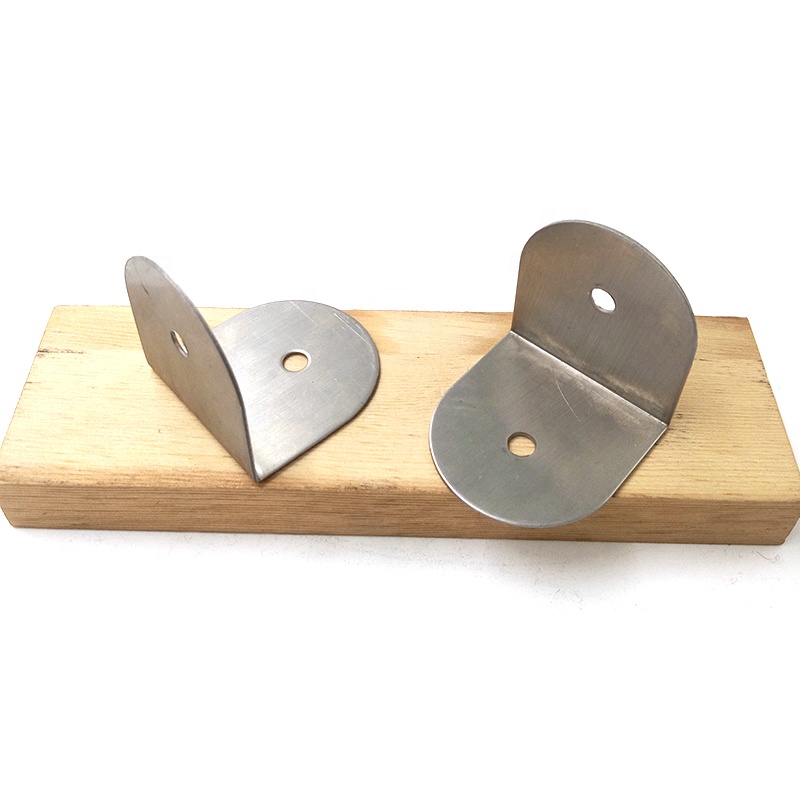

Manufactured using advanced multistep progressive dies, High Hardness Stainless Steel Angle Sheet Metal Corner Stamping Bracket undergo precision stamping, supported by techniques like machining and iron casting. These brackets are crafted from diverse materials including aluminum, copper, brass, stainless steel, steel, iron, alloy, and zinc, these brackets, with a thickness of 1.0mm, offer exceptional strength. Available in silver, black, coppery, yellow, white, and more, they cater to various preferences. Surface treatments such as anodizing, brushing, galvanizing, laser engraving, silk printing, polishing, and powder coating enhance durability and aesthetics. Certified with ISO 9001, these brackets endure rigorous tests, including 48-hour salt-spray, 2D, and plainness testing. Offering OEM/ODM customization, they represent superior quality and reliability, meeting diverse requirements effectively.

Manufactured using advanced multistep progressive dies, High Hardness Stainless Steel Angle Sheet Metal Corner Stamping Bracket undergo precision stamping, supported by techniques like machining and iron casting. These brackets are crafted from diverse materials including aluminum, copper, brass, stainless steel, steel, iron, alloy, and zinc, these brackets, with a thickness of 1.0mm, offer exceptional strength. Available in silver, black, coppery, yellow, white, and more, they cater to various preferences. Surface treatments such as anodizing, brushing, galvanizing, laser engraving, silk printing, polishing, and powder coating enhance durability and aesthetics. Certified with ISO 9001, these brackets endure rigorous tests, including 48-hour salt-spray, 2D, and plainness testing. Offering OEM/ODM customization, they represent superior quality and reliability, meeting diverse requirements effectively.

Specification

Materials: aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc.

Material Thickness: 1.0mm

Color: silver, black, coppery, yellow, white, black, etc

Tolerance: 0.01mm

Mould: Multistep Progressive Dies

Production Technology: Stamping

Process: stamping, machining, iron casting

Surface Treatment: anodizing, brushing, galvanized, laser engraving, silk printing, polishing, powder coating, etc

Certifications: ISO 9001

Test: 48H salt-spray testing, 2D testing, plainness testing

OEM/ODM: available

Packing: plastic bag, carton and pallet or according to customer’s needs

Application: furniture, industrial, construction, electronic, appliance, automotive

Surface Treatment

- Anodizing: Anodizing enhances corrosion resistance and provides a protective oxide layer, ensuring the bracket’s durability, especially in harsh environments.

- Brushing: Precision brushing creates a textured finish, enhancing both visual appeal and touch. This technique adds a sophisticated and unique appearance.

- Galvanized: Galvanization forms a zinc coating, fortifying the bracket against rust and environmental factors. It ensures prolonged usage and maintains the bracket’s structural integrity.

- Laser Engraving: Laser engraving allows for intricate designs and markings, ensuring product traceability and customization options for specific applications.

- Silk Printing: Silk printing offers detailed branding and labeling, providing a professional finish. It ensures clear identification and adds a polished look to the bracket.

- Polishing: Polishing results in a smooth, reflective surface, enhancing the bracket’s aesthetics and giving it a sleek, high-quality appearance.