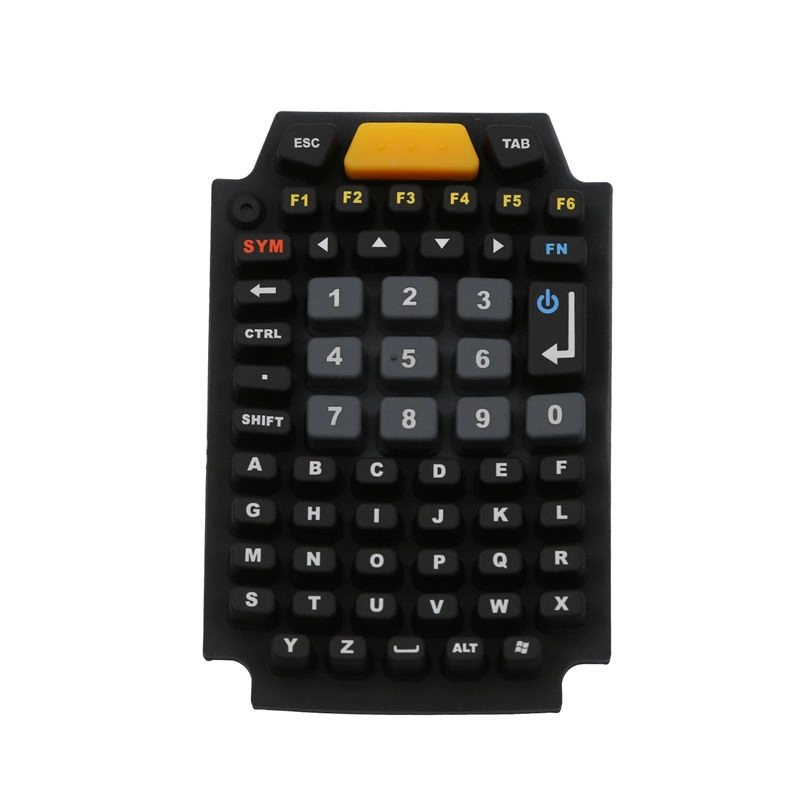

Silicone rubber keypads are the perfect choice for a wide range of custom and customized designs. With excellent operating temperatures ranging from -40℃ to +250℃, they offer superior durability and a high level of ability to withstand extreme environments. This makes them ideal for a variety of industrial, commercial, and household applications. In addition, they can be customized with optional backlight for added visibility, making them even more versatile. Made from quality silicone rubber, these keypads are designed to last and can be customized to fit whatever design you need.

- Thickness:Customized

- Surface:Matte/Glossy

- Material:Silicone Rubber

- Application:Industrial, Commercial, Household

- Color:Customized

- Shape:Customized

Features:

- Silicone rubber keypads with customizable logo and size

- High quality and durable for more than 1 million cycles

- Customizable design with long service life

Customization:

- Customer Requirement Analysis and Specification Determination

- Material Selection and Silicone Formulation

- Mold Fabrication and Customization

- Key Characteristics and Tactile Design

- Labeling and Printing

- Backlighting and Indicator Integration

- Dust and Waterproofing Treatment

- Quality Control and Testing

Packing and Shipping:

Our factory will professionally package&shipp the products according to customer specifications and arrange for suitable delivery methods to ensure the safe arrival of the products.