Overview:

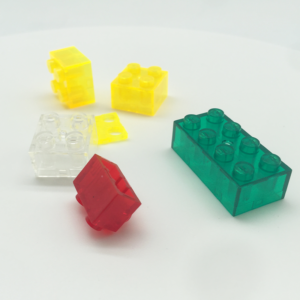

Silicone teethers are primarily made via liquid silicone rubber (LSR) injection molding, a high-precision process where platinum-cured, food-grade silicone is injected into custom-designed molds under controlled heat and pressure. This method ensures seamless, non-porous surfaces, consistent texture, and smooth edges critical for infant safety. LSR molding supports complex shapes, vibrant colors, and hypoallergenic properties, aligning with FDA/LFGB compliance. The technique enables mass production with strict hygiene standards, ideal for OEM/custom designs tailored to brand specifications.

![]()

Characteristics:

| Attribute | Details |

| Age Range | 0 to 24 Months, 2 to 4 Years |

| Place of Origin | Xiamen, China |

| Gender | Unisex |

| Brand Name | OEM |

| Style | Cute |

| Feature | 100% Food Grade Silicone Teether |

| Color | Pink, Green, Grey, Custom |

| Size | Custom |

| Weight | Custom |

| Package | Opp Bag, or Custom |

| Certification | CE, LFGB, ROHS, ISO9001 |

| MOQ | According to your requirement |

| Samples | Accept Custom Sample Service |

Benefits of Our Products:

- Food Grade Materials

- 100% BPA-Free

- Baby Hand Protection

- Lightweight for Baby

Production Process:

- Material Selection: High-quality, non-toxic, food-grade silicone is carefully selected to ensure safety and durability.

- Molding: The silicone material is molded into the desired teething shape using precision injection or compression molding techniques.

- Curing: The molded silicone undergoes a heat curing process to enhance its strength, flexibility, and non-toxic properties.

- Quality Control: Each product is thoroughly inspected for defects and compliance with safety standards.

- Cleaning and Sterilization: Products are cleaned and sterilized to meet hygiene requirements before packaging.

- Packaging: The finished products are packaged, often in custom packaging, and prepared for shipment.

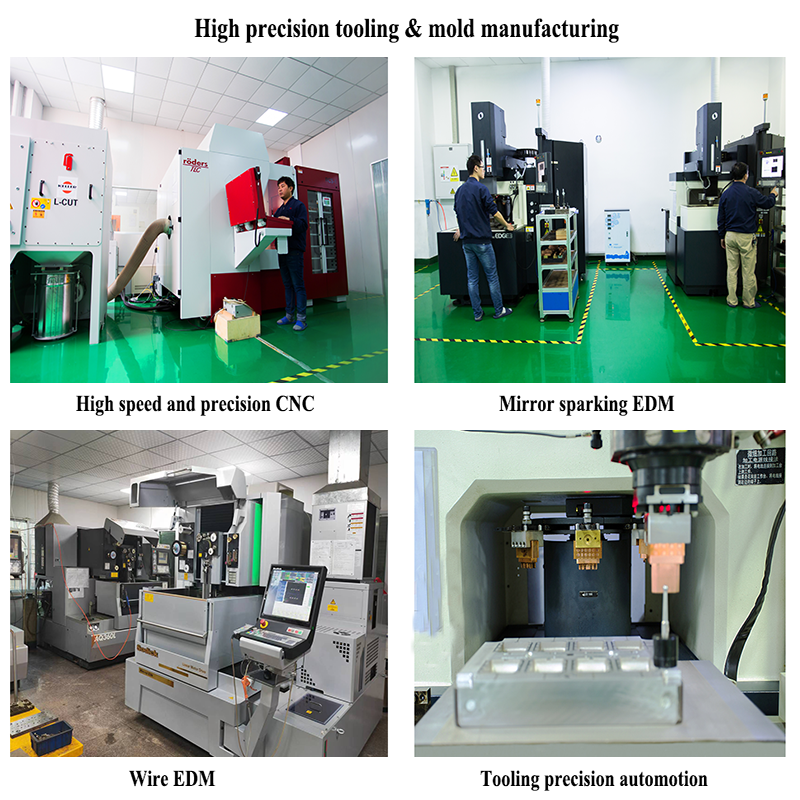

Our Factory Show:

Our facility is equipped with state-of-the-art mold-making technology, including CNC, Mirror EDM, EDM, and Slow-speed Wire Cut WC machines, alongside advanced production lines featuring 15 rubber compressive machines and 2 LSR injection machines. We utilize precision tools such as 3D projectors, sealing testers, and durometers, supported by a skilled QC team, to uphold stringent quality standards. Our mechanical equipment includes AutoDryer Lines, automatic screen printing, 3D measuring instruments, and high-speed doming machines, ensuring the highest production efficiency. With ISO9001 and IATF16949 certifications, our automated processes and rigorous quality control guarantee superior product quality.

![]()