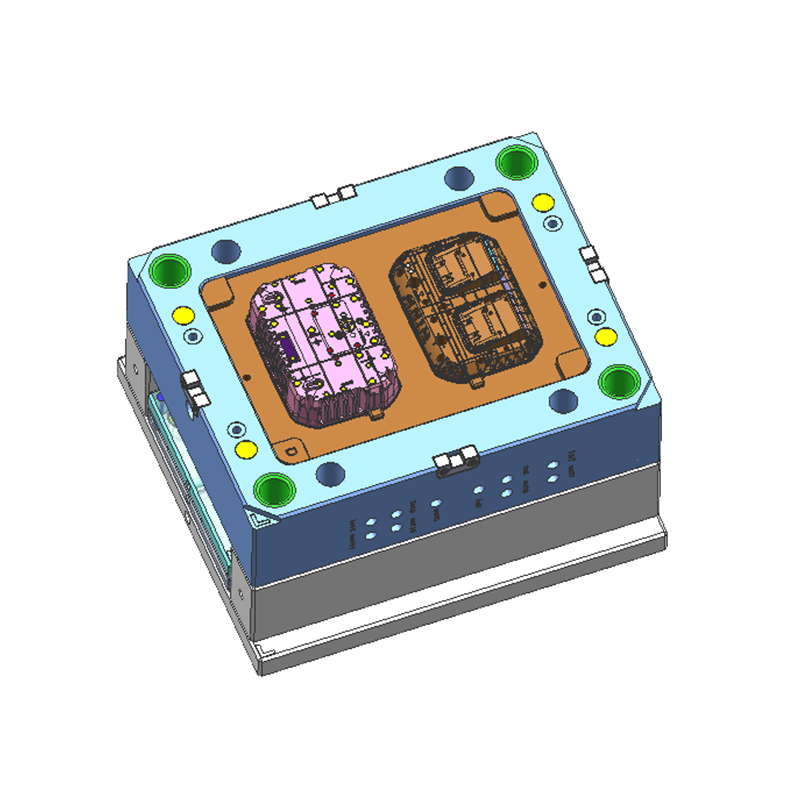

Factory Case Accessories Electronic Battery Mold Plastic Box Mould

Explore YJC’s extensive battery box production line, meticulously designed for the power battery containers of new energy vehicles. As electric vehicle sales surge, the demand for our Battery Box Moulds has skyrocketed.

Our molds ensure unparalleled protection and longevity for your batteries. Through precision design and superior construction, they provide a secure and snug fit, effectively preventing any damage or leakage. By selecting the right mold, you have the power to optimize your battery’s performance, extending its lifespan and enhancing overall efficiency.

In response to the growing market dynamics of electric vehicles, our Battery Box Moulds are engineered to meet and exceed industry standards. With a commitment to innovation, YJC stands at the forefront, providing solutions that not only protect but elevate the performance of your batteries, contributing to the sustainable future of transportation.

Understanding the intricacies of Injection Battery Case Mold

- Injection Molding Essentials:

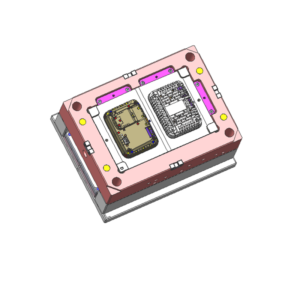

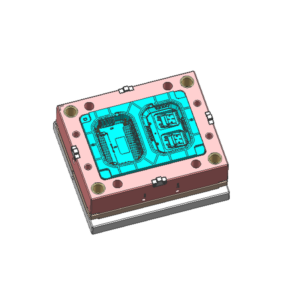

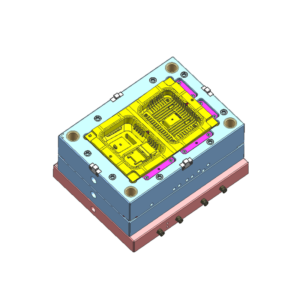

Injection molding is the cornerstone of battery case production, employing two steel plates—the core and cavity plate. These plates, easily installed in small injection machines, allow for direct shaping of the desired battery case.

- Tailored Complexity:

Battery case molds vary in complexity, accommodating the diverse needs of factory case accessories. Advanced molds feature additional cooling channels for precise temperature control and incorporate mechanisms for efficient molding ejection.

- Innovative Mold Design:

Modern molds boast innovative features such as sliding blocks for undercut sections, unscrewing devices for threaded moldings, and a hot plastic in runner. These elements contribute to a streamlined and versatile molding process, enhancing overall efficiency.

- Efficient Ejection Systems:

Ejecting moldings post-injection involves the use of hydraulic devices or compressed air applications, showcasing the adaptability of the production process. These mechanisms ensure smooth operations and timely mold release.

- Exploring Electronic Battery Molding:

Embark on a journey through the intricacies of electronic battery molding for factory case accessories. From injection molding basics to innovative mold design and efficient ejection systems, our process ensures high-quality battery case production.

Experience the precision and versatility of Factory Case Accessories Electronic Battery Mold Plastic Box Mould, where every detail counts in crafting superior factory case accessories.