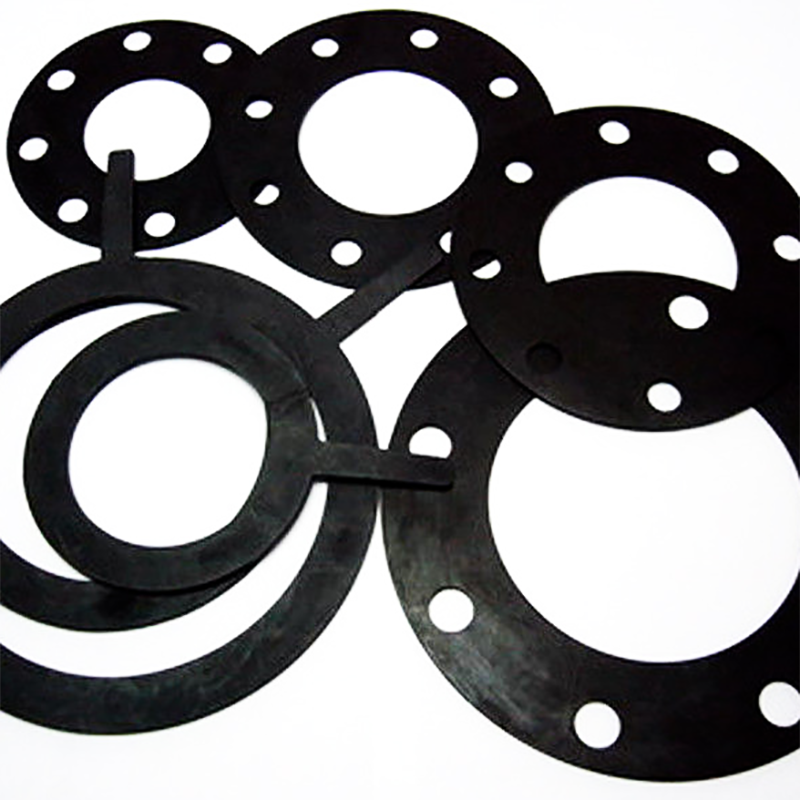

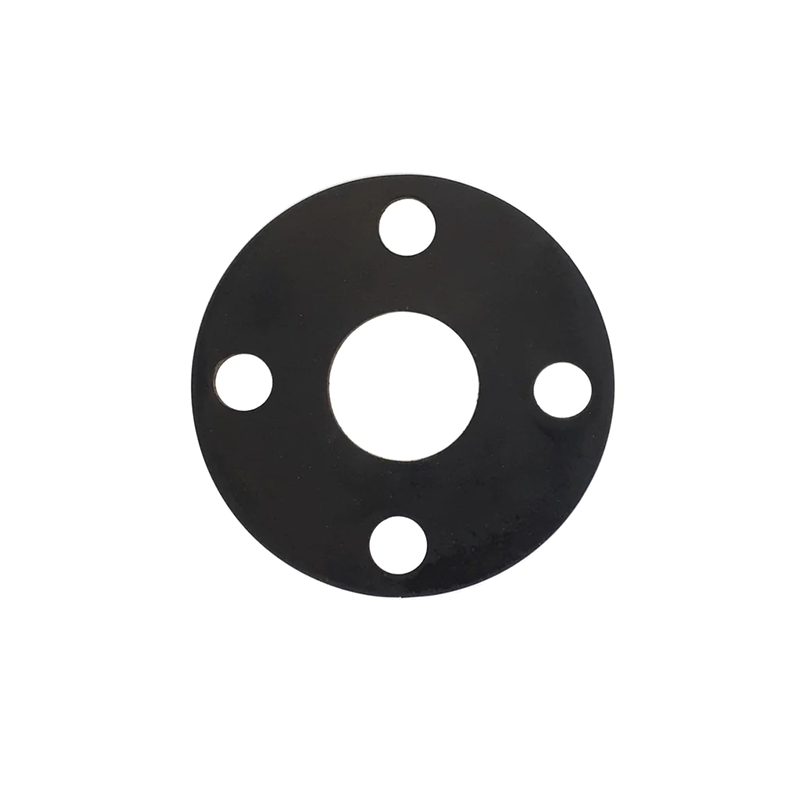

EPDM gaskets for medical and scientific, electronics, and industrial applications. We use precision die cutting to convert sheets and rolls of EPDM gasket material, and can achieve tight tolerances in a wide range of gasket sizes.

What Is EDPM Rubber?

EPDM is ethylene propylene diene monomer, an extremely durable synthetic rubber. According to ASTM D-1418, a standard classification system for elastomers, EPDM is an M-class rubber. SAE J200 and ASTM D2000 also use lettered callouts for EPDM rubber, an elastomer with numerous advantages.

Advantages of EPDM Rubber Gaskets

EPDM rubber gaskets provide reliable, long-term sealing in extreme weather conditions and over a wide range of temperatures. Compared to other rubber materials, EPDM offers excellent resistance against aging, wear, wind, weather, ozone, and ultraviolet light.

EPDM rubber is also color-stable, which means that EPDM gaskets won’t stain mating surfaces. EPDM gasketing also provides good electrical insulation; however, custom gaskets made of EPDM rubber are not recommended for contact with most oils, gasoline, halogenated solvents, and concentrated acids.

EPDM Gasket Material Types and Grades

Die cut EPDM gaskets are made of solid, sponge, or foam rubber materials. Each EPDM gasket material has a distinct molecular structure. Physical properties such as hardness or durometer are important to consider. Solid EPDM gaskets are harder and typically more resistant to compression. EPDM gasket materials are also categorized by grades such as commercial, FDA-approved, UL 94 flame-retardant, and peroxide-cured.

1.Solid, Sponge, and Foam Rubber EPDM Gaskets

Solid EPDM gaskets and sponge rubber EPDM gaskets are available in a range of durometers. Foam rubber EPDM is characterized by closed cells or open cells. Custom EPDM gaskets made of closed cell sponge rubber are used in HVAC systems, electrical enclosures, and door and window seals on cars. Die cut EPDM gaskets made of open cell sponge rubber are used in applications such as shock absorption and electrical insulation.

2.Commercial vs. Higher Grade EPDM Gasket Materials

Die cut gaskets made of commercial-grade EPDM provide good resistance to chemicals, ozone, weathering, and UV light. Typically, these EPDM gaskets are used in applications that require resistance to hot and cold water, saturated steam, and outdoor environments. Higher-grade EPDM rubber materials offer enhanced material properties, and may be recommended if a lower compression set is required.

3.UL 94 EPDM Rubber Gaskets

UL 94 gaskets that are made of flame-retardant EPDM rubber meet UL burn tests such as V-0, V-1, and V-2 and are often halogen-free. Die cut custom gaskets made of UL-rated EPDM sponge rubber and EPDM foam rubber also provide good sealing and moderate-to-good cushioning.

4.Peroxide Cure and FDA Approved EPDM Gaskets

Die cut gaskets that are made of peroxide-cured EPDM rubber provide excellent resistance to aging, heat, and compression set. Typically, they’re used in applications with food, water, and/or steam. FDA-approved EPDM gaskets meet U.S. Food and Drug Administration (FDA) requirements for food contact applications and medical devices. Not all food-grade rubber gaskets are FDA-approved, however.