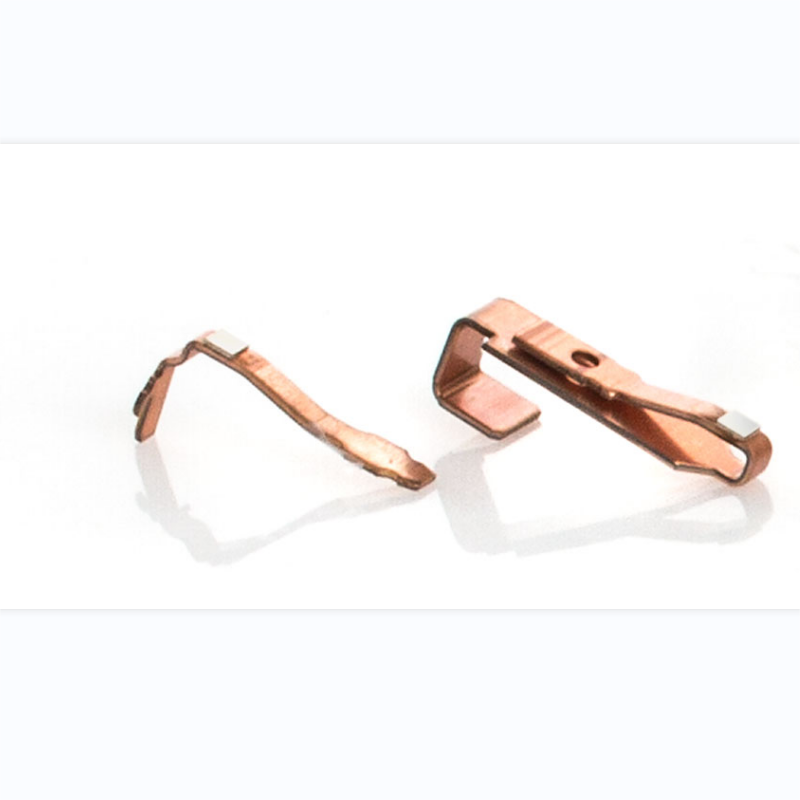

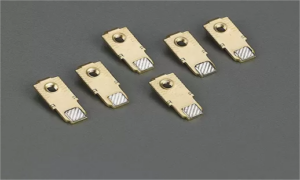

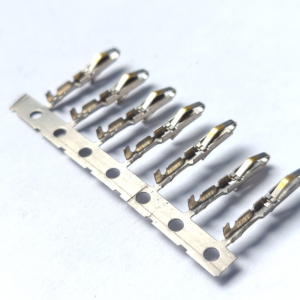

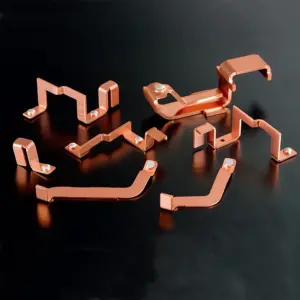

Our Precision Electrical Contacts are fabricated for modern electronic devices, ensuring optimal conductivity and corrosion resistance. Available in various sizes and finishes, they are expertly stamped using deep drawing techniques. Our range includes options like electrical contact sheets, double compound contacts, and bimetal button contacts. We offer tailored customization based on your specific requirements and drawings. Certified with ISO9001, our contacts meet industry standards, ensuring reliability in applications like industrial machinery, automotive, and household appliances. Experience seamless connectivity with our precision-engineered Electrical Contacts.

Specification

Materials: fine silver, agni alloy, agcdon, agcuon, agsno2, agznon, agsn2in2o3, ag-w alloy, cu-w alloy etc

Size: as per customers’ requirement

Tolerance: 0.02mm-0.1mm

Finish: nickel plating, sn plating, tin plating, zinc plating, chrome, heat treatment, plating, degreasing, electrophoresis, etc.

Stamping capacity: deep drawing, shaping metal

Optional Type: electrical contact sheet, double compound contact, three compound contact, plum compound contact, bimetal button contact, welding electrical contact, electrical contact assembly, etc

Services: according to your drawing (PDF, CAD or 3D)

Certificate: ISO9001

OEM/ODM: available

Application: industrial, furniture, automobile, motorcycle, household electrical appliances, computer, etc

Transport Package: as per your requests

Sample Time: 7-12 Days

Lead Time: 15-25 Days

Payment Term: T/T, L/C 30% deposits, before the ship to pay the balance end. Freight are quote under your request

Packages Term: plastic bag, carton and pallet

Delivery Term: by sea/express

Common Surface Treatments

- Galvanized: Metal parts are coated with a layer of zinc, enhancing corrosion resistance and durability.

- Nickel Plated: A layer of nickel is applied to the surface, providing excellent corrosion resistance and a polished appearance.

- Black Oxide: Metal parts undergo a chemical reaction to form a black oxide layer, improving corrosion resistance and adding a sleek black finish.

- Dacromet: An organic coating is applied to enhance corrosion resistance and provide anti-corrosion properties, ensuring longevity and reliability.

- Chrome-Plated: A layer of chrome is electroplated onto the metal surface, offering superior corrosion resistance and an attractive, reflective finish.

These surface treatments for Electrical Contacts Customized for Precision Electronic Devices not only enhance their longevity but also contribute to their functional and aesthetic qualities, ensuring optimal performance in various applications.