Elastomeric Silicone Rubber Pressure Relief Valve

Rubber’ pressure relief valves are used for controlling the direction of flow of a fluid, Designs can includeumbrella valves, duckbill valves, Belleville Valves and diaphragm valves etc.

Rubber pressure relief valves can be designed to provide the customer’s required head loss and flow rate forparticular applications.

A range of materials and designs are available to handle different fluids and service conditions.

Rubber Pressure Relief Valve, mostly used in the Patient Valve for Manual Resuscitator.

Elastomer Rubber Pressure Relief ValvePressure relief valves are unique, one-piece, elastomeric components that act as backflow prevention devices or one-wavalves or check valves. They have elastomeric lips in the shape of a duckbill which prevent backflow and allow forward flow.

The main advantage of silicone pressure relief valves over other types of one-way valves is that Pressure relief valves are selfcontained i.e.the critical sealing function is an integral part of the one piece elastomeric component as opposed to valve:where a sealing element has to engage with a smooth seat surface to form a seal.

Therefore elastomer pressure relief valves are easily incorporated and assembled into a wide variety of devices without thehassle or problems associated with the surface finish quality of mating seats and/or complex assembly processes.

Basic informatlon:

1.Common Valve types:Duckbill Shaped Valves, Umbrella Shaped Valves, Flapper Shaped Valves and other custom made valves etc.

2.USAGE:Medical Devices Valves, Industrial Devices Valves, Aerospace Devices Valves, and 0il/G-AS Devices Valves etc.

3.Medical Devices Valves.

Medical Grade Silicone Valves and Dust-Free Silicone RubberProduction Plants Respiratorv and Anesthesia Circuit Devices Valves.

Our Advantage:

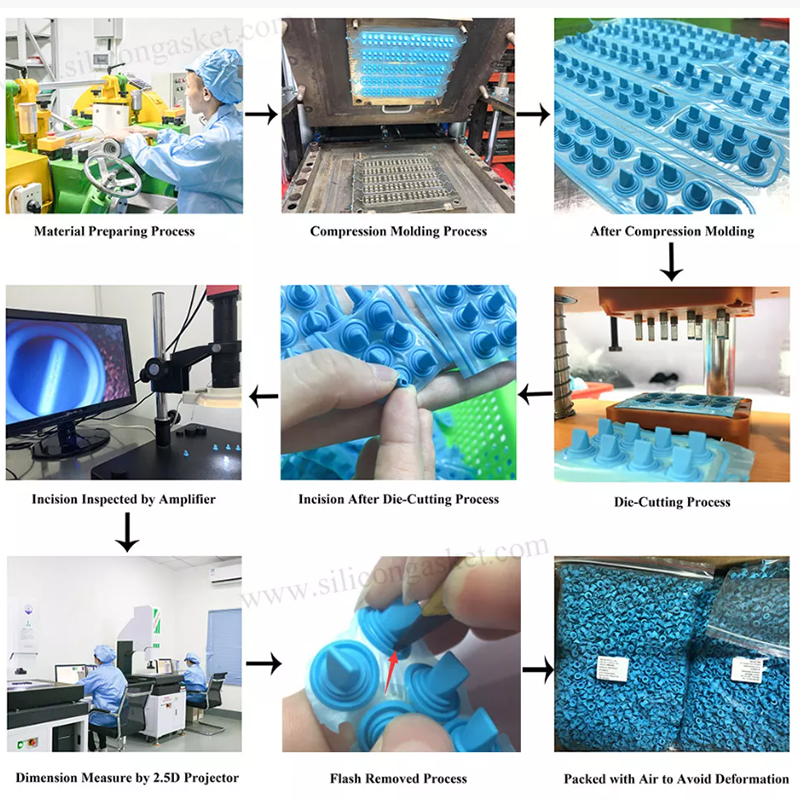

l.Precision Mold-Making Technology (Since 1998)

2. Competitive Price: Origin Manufacturer.

3. Five experienced designers: offer technology/production/design/artwork support etc.

4. Production and Test strictly according to ISO9001

5. Complete Production Plant, Equipment, Environment

Other not less important features include:

1)Position independent,

2)Low opening pressure- immediate free flow.

3)Non-tortuous flow path.

4)High flow rate vs. package size.

5)Virtually no internal volume and dead space.

6)Particle compliant.

7)Corrosion resistant

8)Wear resistant

9)very cost effective