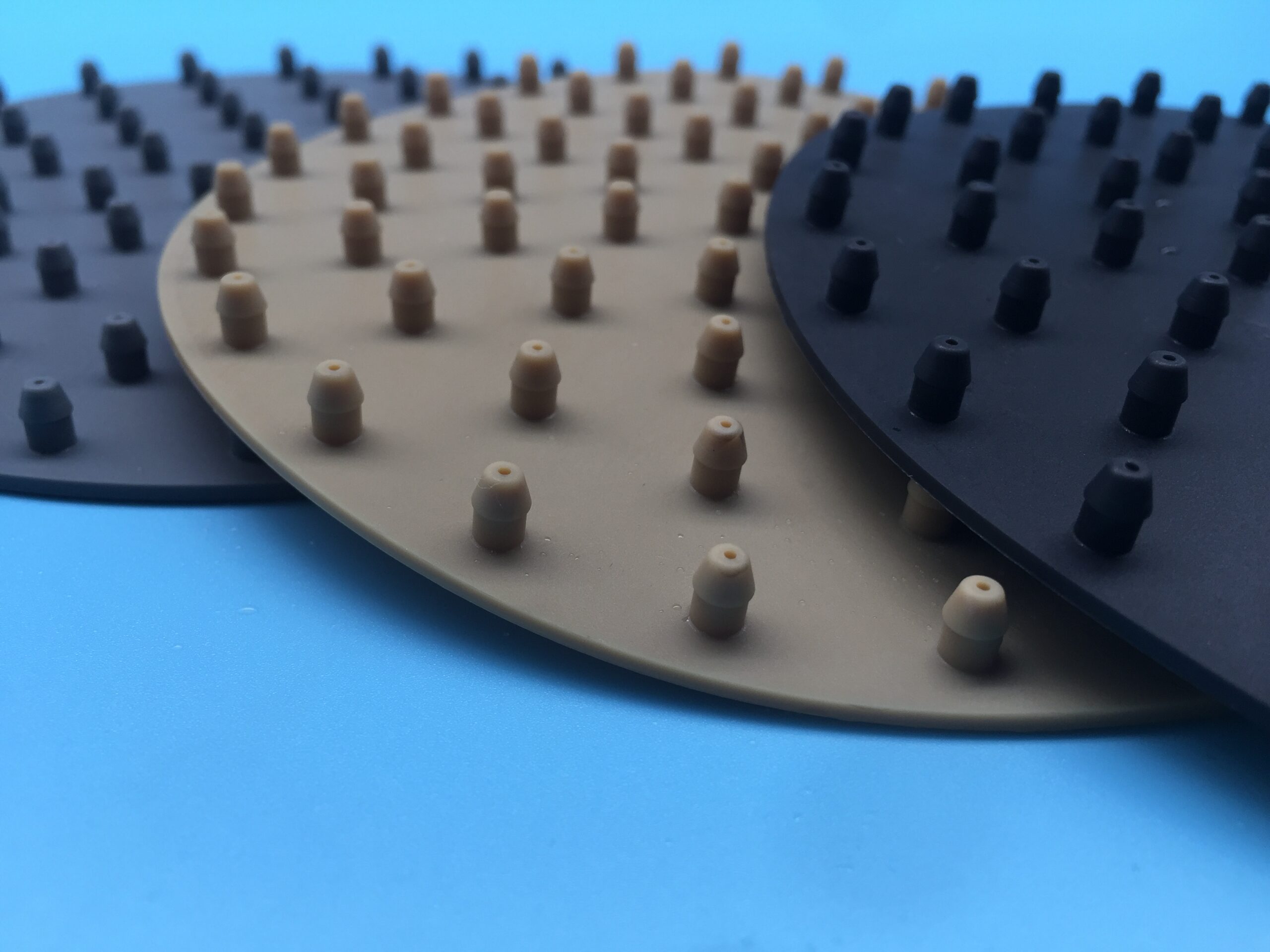

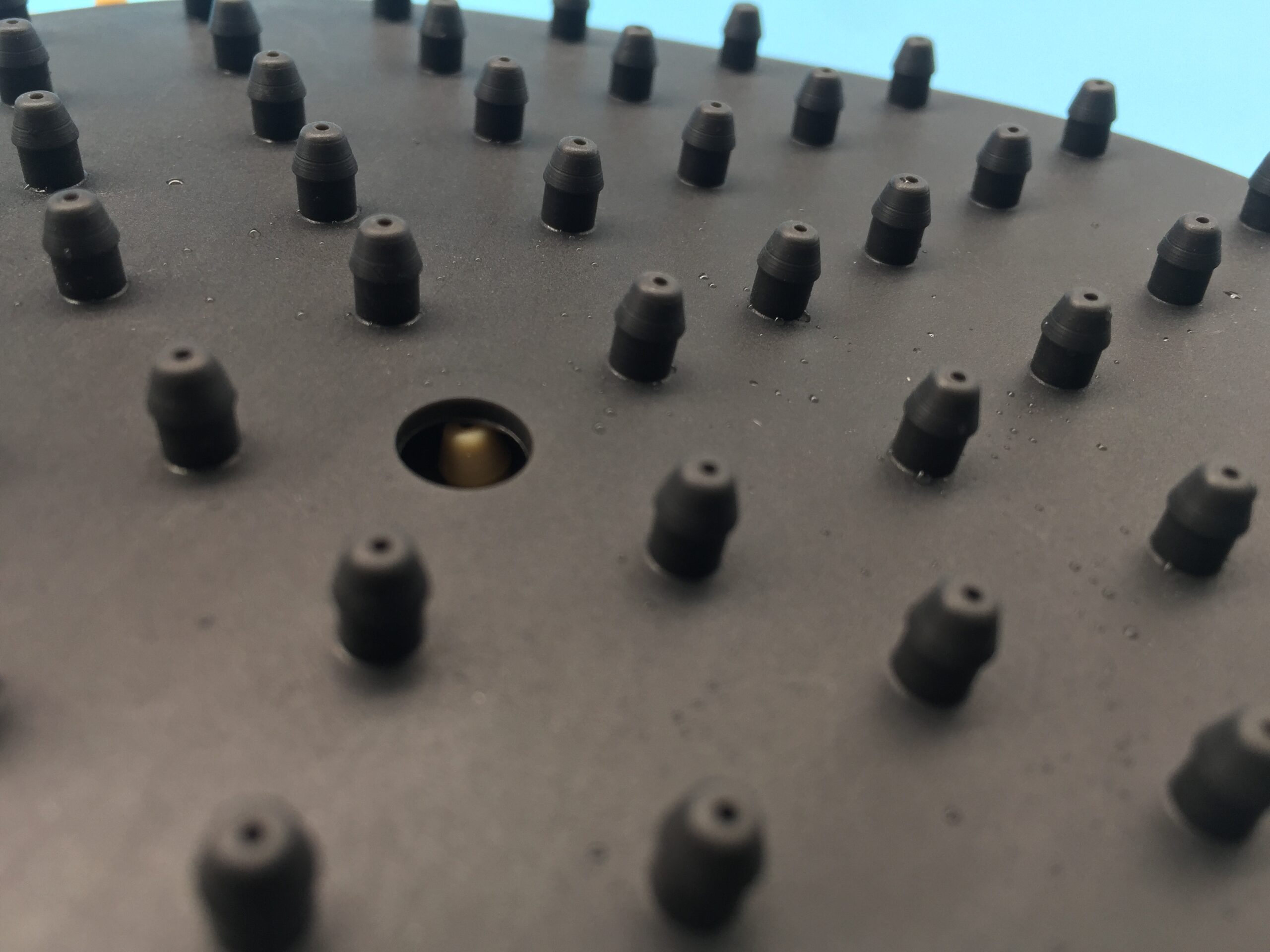

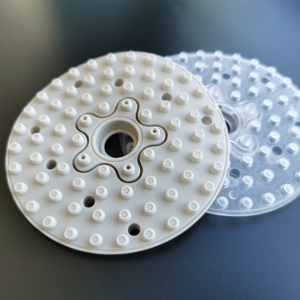

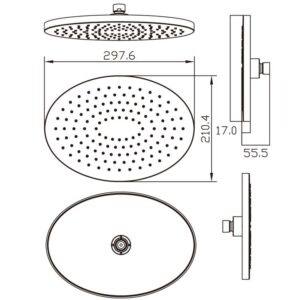

Elastic silicone rubber nozzles mostly use in shower head nozzles, faucet, tap products,sprinkler etc. Mold making, silicone rubber nozzle burr control, and nozzles structure will key to water’ or’ aispray splash effects.

OEMM/ODM Service:

1. Offer 2/3 D design Drawings

2. Design and Size Tolerance Demands

3.Hardness Demands

4.Hardness Tolerance Demands

5.Production Environment Demands7.Certification Demands(ASTMDIN.JIS, IsO and SGS etc)

6.Materials Demands

7.Certification Demands(ASTM,DIN.JIS, IsO and SGS etc)

8.Production Enyironment Demand

Why Choose Us to Custom Silicone Shower Rubber Nozzle?

1. Own Mold Tools Technology

2 Short time finished samples and products

3.Precision mold-making technology since 1998

4.Production Experience:Focus on and began to produce silicone/ubber Shower Head Gasket /Nozzle for many years.

5.Original Manufacturer

6.Four Production Plants and One Assembly Plant:Mold-Making Plant;Silicone Rubber Compression Plant;Plastic Injection Plant;LSR Injection Plant(Dust-Free Clean Room);Assembly Plant(Dust-Free Clean Room)

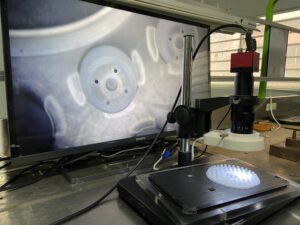

Silicon Rubber Nozzle Mold tooling Making:

For better silicone rubber water nozzles, making mold tooling for need three layers mold plates and also needpunch needles. Some need four layers mold plates for under-cut nozzles.Machines holes in mold plate by WEDM-LS for assembling the punching needles. Each holes spacing mostlabove 0.5mm. Installing the punching pin, need think of the nozzles structures etc.

When silicone rubber nozzles mass production appear the rubber burr, should be stop production, anddismantle for needle repair or change brand new one. Silicone rubber’ nozzles burrs will affect the water’ spouteffects.That can make sure each nozzle quality when mass production, and also can save production fime and themould tooling maintenance cost.

The Influence of Shower Head Nozzles to the Water Flow:

As the terminal of the shower head, the size and structure of the nozzles make a great inflence on water flow capacity.There are three kinds inner hole of nozzles: round hole, rectangle hole, triangle hole and so on, However; the spray shape oithe round hole is much better than the other two types. Under the same Reynolds number; as the spraver of round nozzlestends to flows along the center line, the possibility of second flow is less.

The showerhead nozzlessome structures. like thin-walled orifices(a). extendedcvlinder nozzles(b).lavenozzles(c. shrink coneexpanded cone nozzles(el. and streamline nozzles.nozzlesiC

inserted cylinder

1.Compare with extended cylinder nozzles, because the flow disturbance in the entrance area is increased, under the same flow capacity, the flow rate of inserted cylinder nozzles is slow.

2.The water outlet area is smaller than the water inlet area, the flow speed of inserted cylinder nozzles is slow than extended cylinder nozzles

3.The water outlet area is bigger than the water inlet area, the flow speed of inserted cylinder nozzles is fast than extended cylinder nozzles

4.As will not form no vacuum and have not suction force, the flow capacity of streamline is also not maximal.