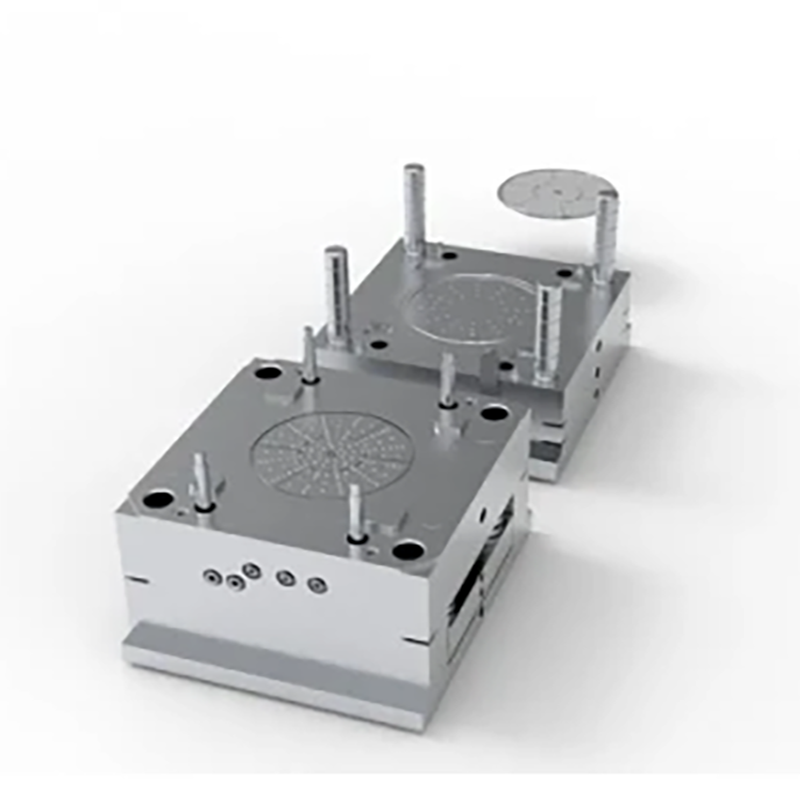

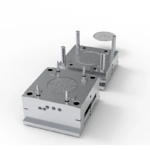

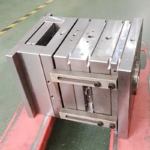

LSR Over-molding Shower Head Mold Design

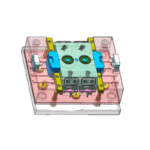

Due to the high expansion coefficient of LSR, expansion occurs when heated, while slight contraction occurs when cooled

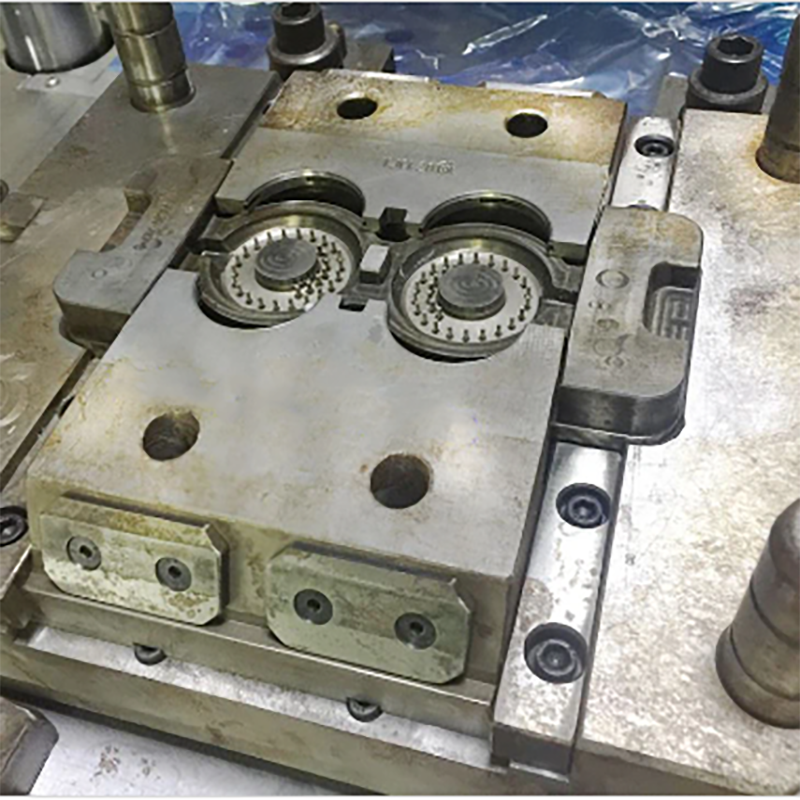

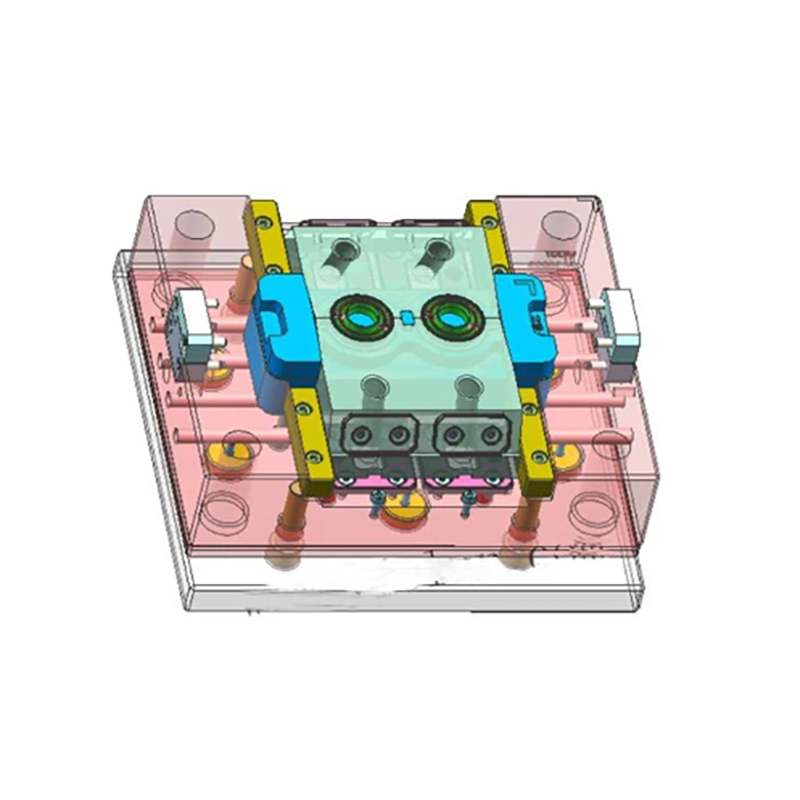

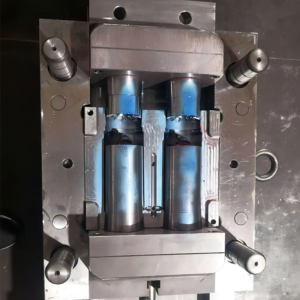

This part cannot maintain accurate margin in the die. Therefore, cold runner processing can be used, and LSR should be protected

With lower temperature and fluidity, the cold runner USES a closed system, in the injection cycle, the closed system in each

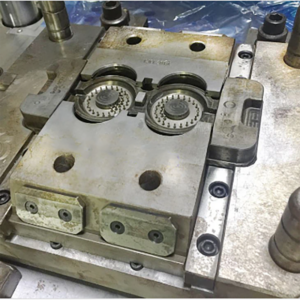

Each flow channel adopts “sealing needle” or “needle valve” to control the accurate measurement of LSR material.

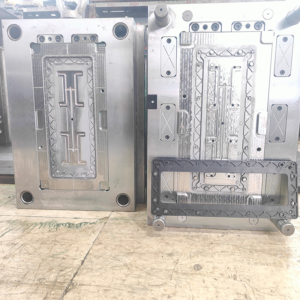

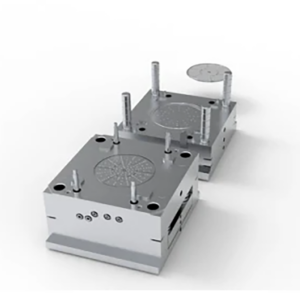

LSR over-molded shower head accessories mold specification

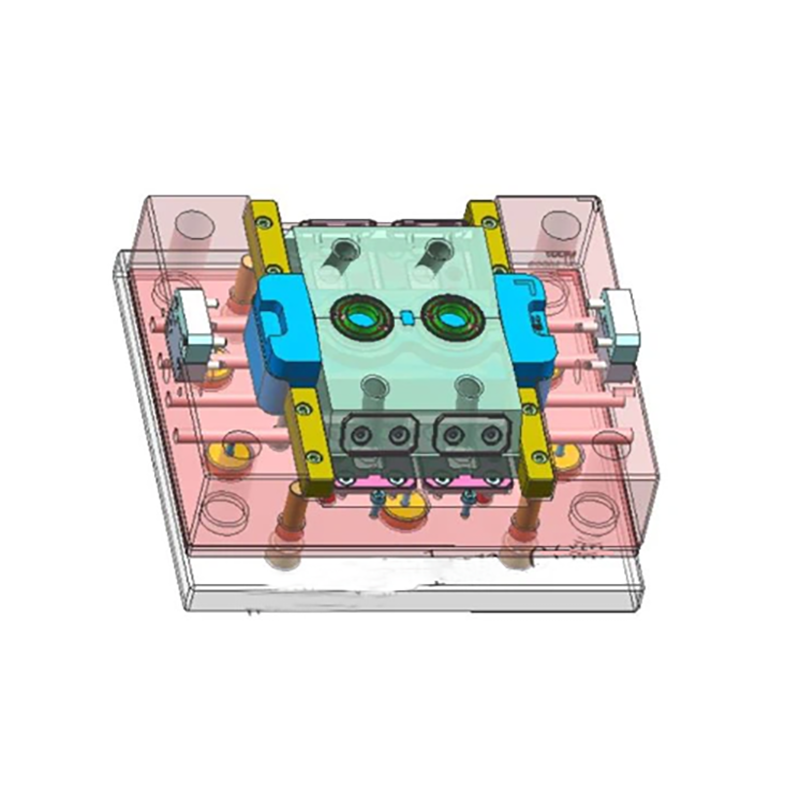

| Mold type | Two-plate with slider | Gate type | Valve gate |

| General thickness | 0.5-2.1mm | Runner brand | Cold runner |

| Material | LSR | shrinkage | 0.3% |

| Part weight | 6.5g | NO. of gate | Each product ONE |

| Cavities | 1*2 | Injection machine | LSR Vertical injection machine |

| Surface | EDM-VID21-24 | Cycle time | 70-100s |

| Cavity steal | S136(HRC48-50) ASSAB | Core steal | S136(HRC50-52) ASSAB |

Liquid Silicone Rubber is a kind of non-toxic, heat-resistant and highly resilient flexibility. The rheological behavior of thermosetting materials is mainly characterized by low viscosity, rapid curing, thinning shear and higher Coefficient of thermal expansion. LSR is a dual-liquid rapid vulcanization material with platinum as catalyst, which can be used in injection molding. Mass, rapid vulcanization, repetitive mechanical production.

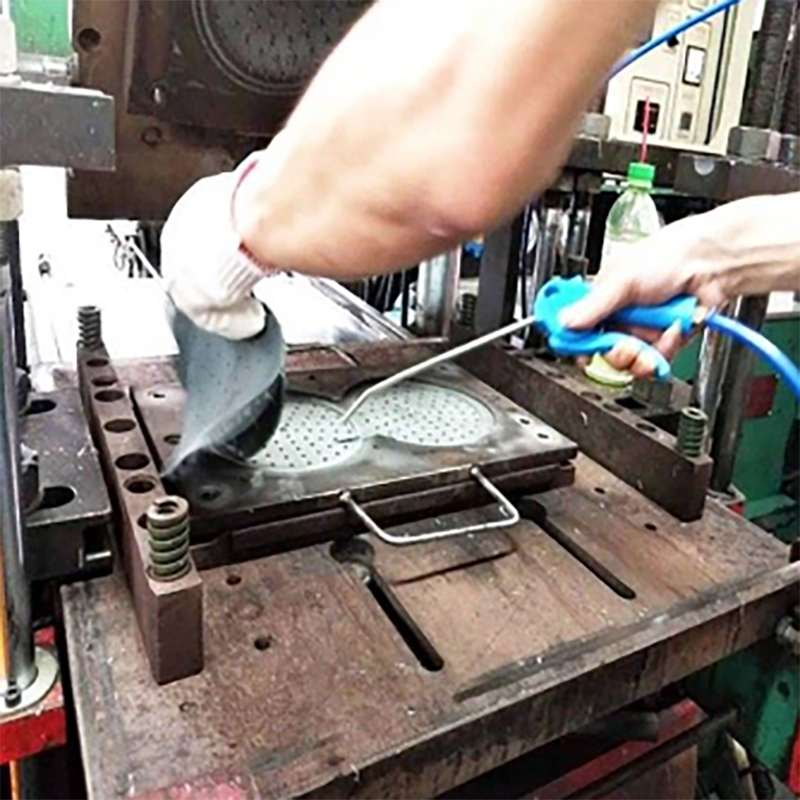

Silicone injection shower head accessories mold application

YJC Silicone Parts is a high-end provider of produced parts using the insert plastic molding process for major OEMs. Our advanced manufacturing capabilities, excellent quality control, and many years of exclusive experience with LSR components make us an ideal partner for your next project.

Our service

- One-stop service

- DFM Moldflow

- Tool designing

- Focus on tool life and mold making

- Multi-component LSR product

- High precision, complex structure of LSR products

- Molding & Post molding

- Experience and Patents

- YJC has comprehensive Quality Management system

In the phase of the product development, our designers have a strong communication ability with customers. To the question of diversification and complexity of product structure, designers will analyze the structure by using software, and propose the clear practical solution.