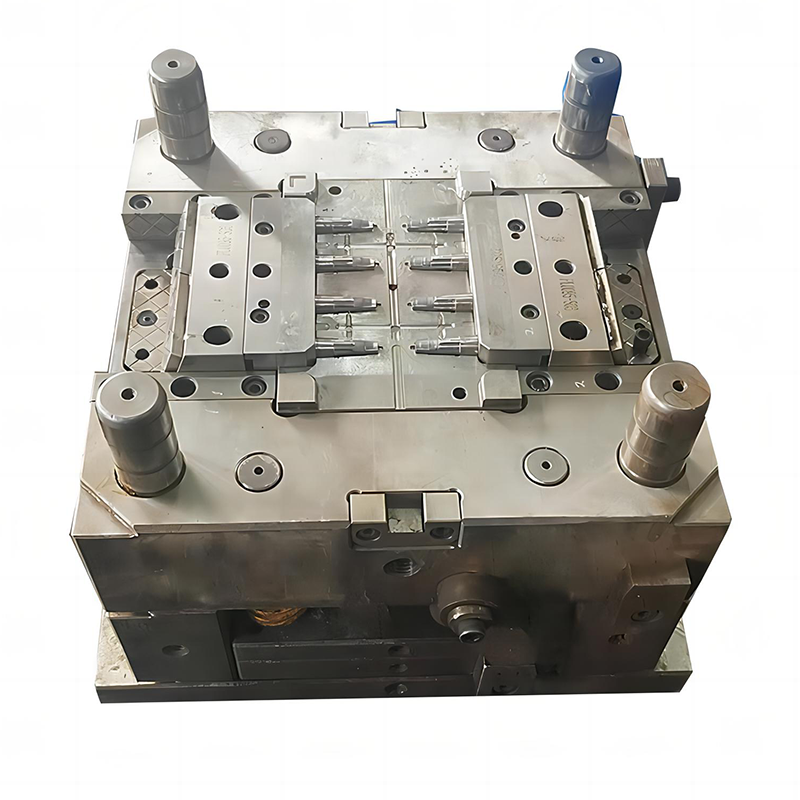

High-Precision Mold for Medical Device Joints

Our precision mold, engineered for manufacturing medical device joints, stands out with its superior design and material selection. Utilizing premium plastics like PS and mold steel NAK80, it promises unmatched durability and performance. The mold features a cold runner system and a slider mechanism, ensuring smooth ejection and a lifespan of up to 300,000 shots.

Materials and Design

- Plastic Material: We use Polystyrene (PS) due to its excellent biocompatibility and safety, making it ideal for medical applications.

- Mold Steel: Crafted from NAK80 steel, our mold guarantees exceptional hardness and precision, leading to long-lasting quality.

- Runner System: The cold runner system is optimized for efficiency and cost-effectiveness, reducing material waste during the molding process.

- Mold Structure: The slider mechanism effectively handles undercuts, facilitating smooth and reliable part ejection.

Durability and Productivity

Designed for high efficiency and longevity, this precision mold features an 8-cavity design that maximizes production capacity while maintaining the precision and quality of each piece. Its operational life extends to 300,000 shots, offering excellent return on investment and consistent performance.

Applications in the Medical Field

Medical-grade plastics, essential for manufacturing a variety of medical products, are used in our molds to ensure biocompatibility and safety. These products include MRI shells, medical device joints, plastic syringes, and prosthetics. The selected materials meet the required standards for contact with the human circulatory system, providing necessary ductility, hardness, and precision for intricate medical components.

Selecting the Right Medical-Grade Plastic

Choosing the appropriate medical-grade plastic is crucial due to the specific biocompatibility requirements of medical devices. Unlike conventional plastics, medical-grade variants are designed to be safe for use within the human body. Our joint laboratory can help match your product needs with the appropriate medical-grade plastic, ensuring optimal safety and performance.

Tailored Precision Molding Solutions

We offer customized precision molding services to meet your specific injection molding production requirements. Our expertise ensures that each mold is tailored to the exact specifications and demands of your medical devices, delivering high-quality and reliable components for critical medical applications.