Overview:

Liquid Silicone Rubber (LSR) gaskets, produced through LSR injection molding, provide superior precision, safety, and environmental benefits over traditional vulcanized silicone. These gaskets offer high transparency, efficiency, and reduced manual labor, with precise design, size, and dimensional tolerances. In consumer electronics, LSR overmolding on plastic or metal substrates ensures enhanced sealing, durability, and protection against moisture and dust. For custom LSR gasket solutions, contact us for professional and efficient OEM services.

Characteristics:

- Place of Origin: Xiamen, China

- Brand Name: OEM

- Material: Silicone, Plastic

- Size: Customized size

- Color: Custom Color

- Logo: Custom Logo from Customer

- Delivery Time: 20-30 days

- MOQ: Small Order Can Be Accepted

- Drawing Format: STP/IGS/PDF

- Sample: Available

- Certification: ISO 9001:2015

- Package: Custom

Advantages of Our Gaskets:

- Enhanced Sealing Performance

- Precision and Customization

- Durability and Longevity

- Environmental and Cost Efficiency

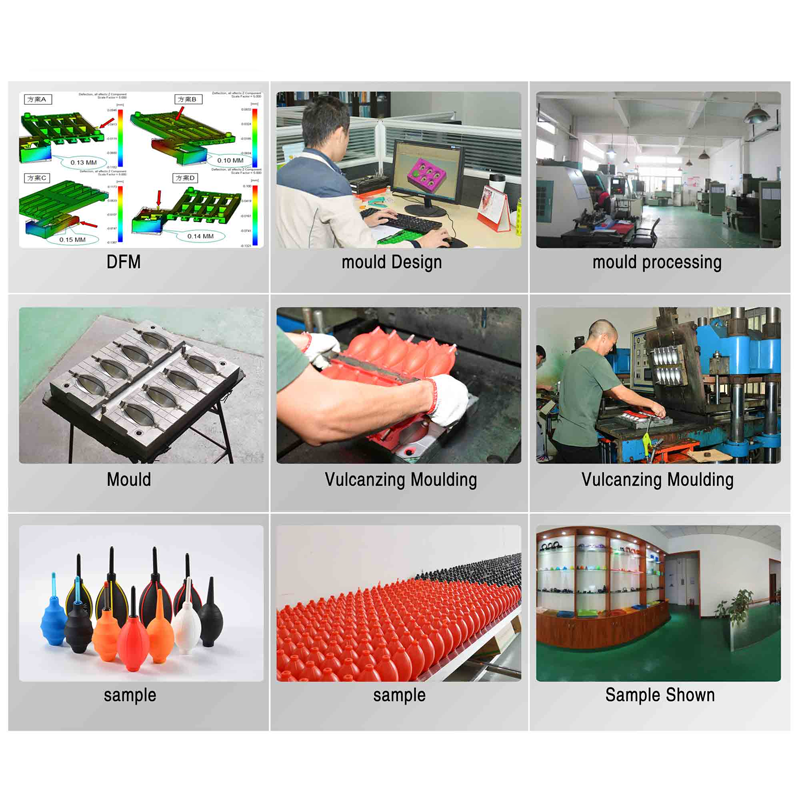

Production Process:

- Design and Prototyping

Custom gaskets are designed based on specific requirements, with prototypes created for testing fit and function.

- Mold Creation

A high-precision mold is crafted based on the design, ensuring durability and accuracy during production.

- Material Preparation

Liquid Silicone Rubber (LSR) is prepared and mixed with additives for optimal performance, ready for injection molding.

- Overmolding

LSR is injected over the plastic or metal substrate, bonding securely with the component in the mold.

- Curing

The molded part is cured to solidify the silicone, ensuring strength, flexibility, and sealing properties.

- Finishing and Inspection

Excess material is trimmed, and the gasket is inspected for quality, including dimensional accuracy and performance.

- Packaging and Delivery

Final parts are packaged and delivered to ensure they arrive in perfect condition.

Our Factory:

We operate advanced facilities equipped with CNC machines, Mirror EDM, EDM, and Slow-speed Wire Cut WC for precise mold-making. Our production lines feature 15 rubber compression machines and 2 LSR injection machines, ensuring efficient and high-quality manufacturing.

To maintain strict quality standards, we use 3D projectors, sealing testers, elasticity measurement tools, durometers, and a skilled QC team. Our mechanical equipment includes an AutoDryer Line, automatic screen printing machines, 3D measurement instruments, high-speed doming machines, and CNC machines.This combination of cutting-edge technology and rigorous quality control ensures consistent, high-quality production.