Overview:

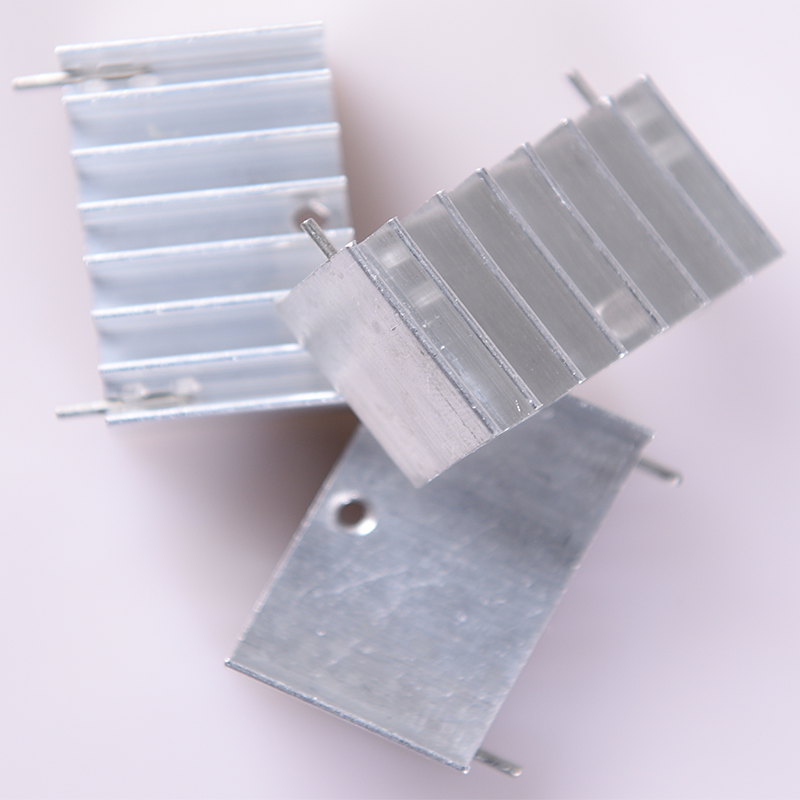

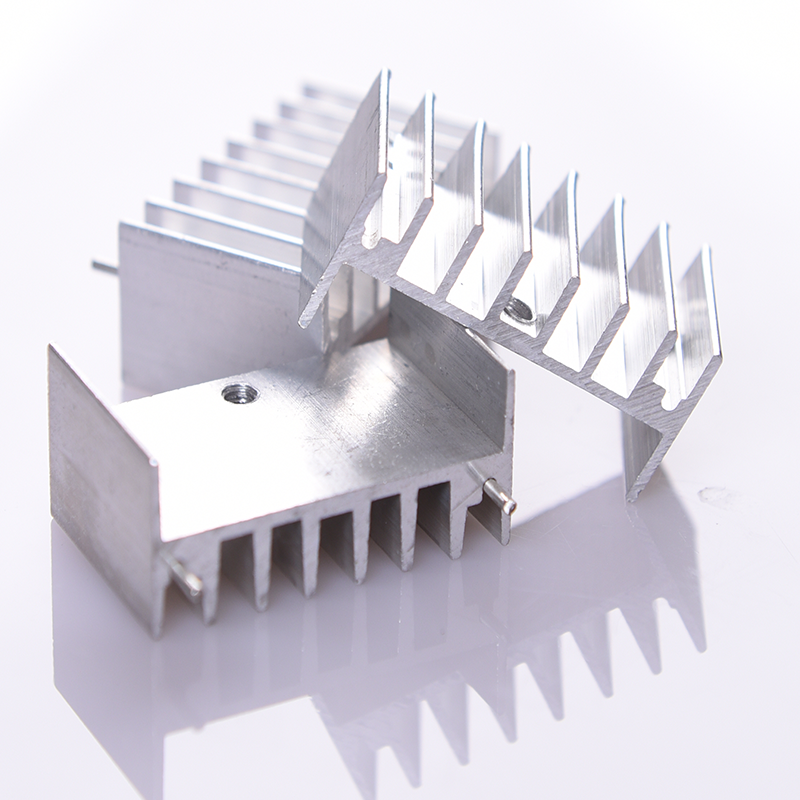

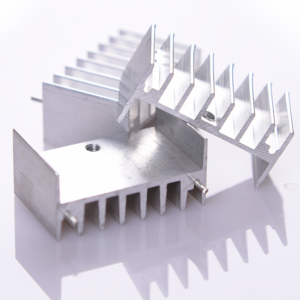

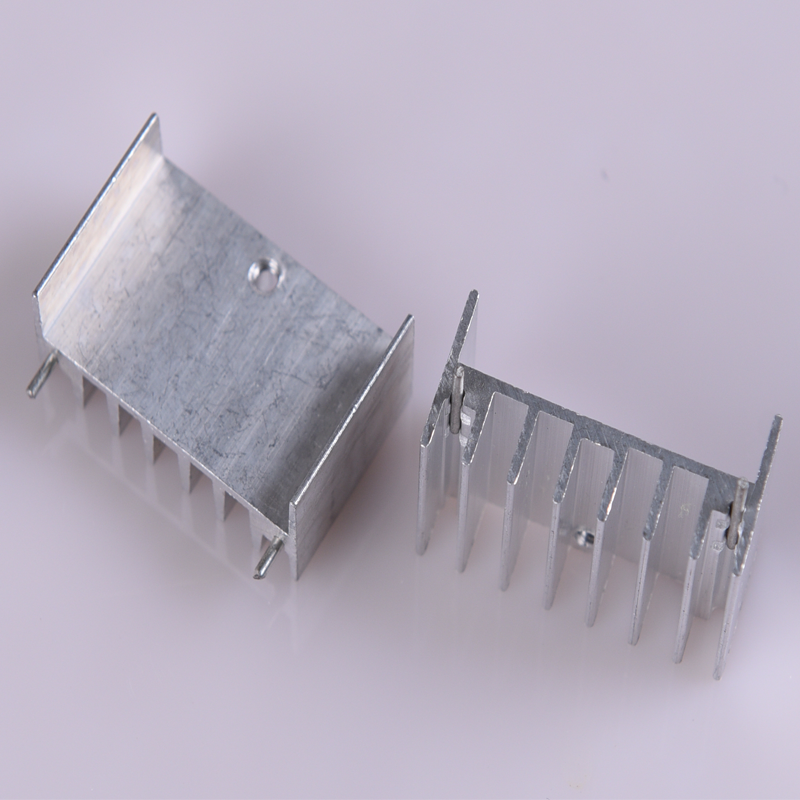

A heat sink for computer applications is a thermal management component made primarily through extrusion, die-casting, or machining, using materials like aluminum or copper for optimal heat dissipation. These heat sinks help prevent overheating, ensuring consistent performance and durability for CPUs and GPUs. We also offer custom designs to meet specific needs, providing reliable thermal management solutions tailored to your requirements.

Details:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Delivery Time | Within 7 days |

| Application | Computer heat dissipation |

| Shape | Custom |

| Processing Services | Bending, Decoiling, Welding, Punching, Cutting |

| Material | Aluminum Alloy |

| Customization | Accept Customized |

| Certification | ISO9001/ROHS |

| Service | OEM |

| Color | As pictured, accepts customization |

| Surface Treatment | Powder Coating, Sand Blasting, Powder Coated, Painting, Mill Finished |

Production Process:

- Design and Prototyping: The process begins with designing the heat sink based on specific thermal requirements and computer application needs. Prototypes are created using CAD software to simulate performance before production.

- Material Selection: High-quality aluminum alloy is typically chosen for its excellent thermal conductivity and lightweight properties. The material is sourced and inspected to meet industry standards.

- Cutting and Shaping: The selected aluminum is cut and shaped into the desired heat sink design using precision cutting methods such as laser cutting or CNC machining. This step ensures the heat sink fits perfectly within the computer hardware.

- Bending and Forming: The aluminum is bent and formed into fins and other structures that maximize surface area for efficient heat dissipation. This is achieved through specialized equipment to maintain accuracy.

- Surface Treatment: To enhance durability and thermal efficiency, the heat sink undergoes surface treatments such as powder coating, sandblasting, or anodizing. These treatments provide corrosion resistance and improve heat dissipation.

- Assembly: If the heat sink design includes multiple components, they are assembled using welding or other joining techniques. The assembly is inspected for structural integrity and alignment.

- Quality Control: Each heat sink undergoes rigorous quality checks, including dimensional accuracy, surface finish, and thermal performance testing. This step ensures that only products meeting strict standards are shipped.

- Customization and Final Inspection: If customization is required, such as specific shapes, colors, or logos, these are applied during the final stages. A thorough inspection is conducted to confirm that the product meets all specifications.

- Packaging and Delivery: The finished heat sinks are carefully packaged to prevent damage during transit. They are then shipped to customers, ready for installation in computer systems.

This structured process ensures that each heat sink is manufactured to deliver optimal thermal management in demanding computer applications.

Factory Show: