Custom Foldable Cup: The Ultimate On-the-Go Companion

At YJCpolymer, we understand the importance of convenience in your busy lifestyle, and that’s why we’ve designed the perfect travel companion – our Custom Foldable Cup. This innovative and compact cup is not just a beverage holder; it’s a game-changer for those who are always on the move. Whether you’re a frequent traveler, outdoor enthusiast, or just someone who values practicality, our Custom Foldable Cup is the perfect blend of style, functionality, and sustainability. Upgrade your on-the-go experience with our innovative solution.

Key Features:

Portable Design: Our foldable cup is ingeniously designed to collapse into a compact size, making it incredibly easy to carry in your bag, pocket, or even attach to your keychain. Say goodbye to bulky and cumbersome travel mugs.

Premium Materials: Crafted from high-quality, food-grade silicone, our custom cup is not only lightweight but also safe for hot and cold beverages. The material is non-toxic, BPA-free, and ensures that your drinks taste just as they should.

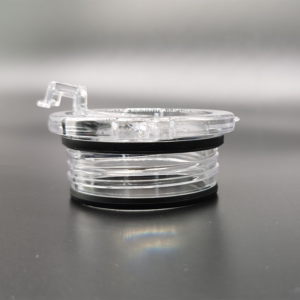

Leak-Proof Seal: Nobody likes spills! Our foldable cup features a secure and leak-proof seal, giving you peace of mind when sipping your favorite drinks on the go. Enjoy your coffee, tea, or any beverage without worrying about messes.

Environmentally Friendly: Join the eco-friendly movement. Our reusable foldable cup helps reduce single-use plastic waste. By choosing our cup, you contribute to a sustainable lifestyle and make a positive impact on the environment.

Processes

Mold Design and Manufacturing:

- Design and customize precision molds based on cup specifications.

- Utilize advanced CNC machining techniques for mold fabrication.

Injection Molding:

- Inject molten silicone into molds to create the cup’s basic form.

- Control temperature and pressure during the molding process.

Shaping and Curing:

- Shape the molded silicone into the final cup structure.

- Subject the cups to high-temperature curing for improved stability.

Printing and Customization:

- Apply customization features such as logos or patterns.

- Use methods like silk printing for durable and clear customization.

Assembly and Quality Inspection:

- Assemble individual cup components.

- Conduct thorough quality inspections to ensure functionality and appearance.