The material characteristics for the Car Battery Charger Plastic Shell/Enclosure are crucial for the performance and safety of the product.

- Mechanical Strength: The material must possess sufficient mechanical strength to withstand physical impacts, compression, and bending, ensuring the structural integrity of the enclosure.

- Chemical Stability: The material should exhibit excellent chemical resistance to resist contact with chemicals associated with the internal electronic components and circuits, such as electrolytes, solvents, or cleaning agents.

- High-Temperature Resistance: As the charger may generate heat during operation, the material must be capable of withstanding high temperatures to prevent softening, melting, or loss of strength.

- Flame Resistance: Some applications may require materials with flame resistance to reduce the risk of fires. Flame-resistant materials can prevent the spread of flames.

- Electrical Insulation: The material must provide good electrical insulation to prevent electrical interference and protect internal electronic components from moisture.

- Weather Resistance: The material should have good weather resistance to withstand the effects of UV radiation, humidity, and temperature variations on the enclosure.

- Sealing Properties: The enclosure material should be able to provide effective sealing to prevent dust, moisture, and other impurities from entering the internal circuits.

- Plasticity: The material must be easy to process and shape to ensure manufacturing efficiency.

- Color and Appearance: The color and appearance of the material may vary depending on product design and branding requirements.

- Recyclability: Considering sustainability, some manufacturers may choose recyclable materials to reduce environmental impact.

Car Battery Charger Plastic Shell/Enclosure materials come in a variety of options and can be chosen based on the product’s performance and design requirements. Here are some common material choices:

- Polycarbonate (PC)

- Polypropylene (PP)

- Polyether Ether Ketone (PEEK)

- Polystyrene (PS)

- Polyvinyl Chloride (PVC)

- Acrylonitrile Butadiene Styrene (ABS)

- Nylon (PA)

- Polystyrene (PS)

- Polymethyl Methacrylate (PMMA)

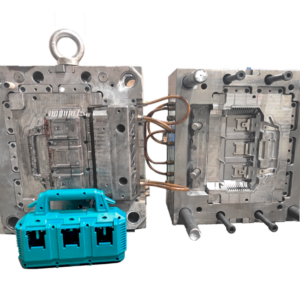

We employ precision injection molding technology in the production of Car Battery Charger Plastic Shell/Enclosure to ensure high-quality, high-precision, and consistent casing. Here are the key features of our injection molding process:

- Mold Design and Fabrication

- Material Selection

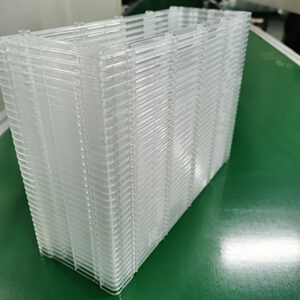

- Precision Injection Molding

- Multi-Material Injection Molding

- Automation and Robotics

- Process Monitoring

- Quality Control

- Environmental Awareness

Our injection molding technology is a comprehensive process encompassing mold design, material selection, process control, quality testing, and sustainability practices. This ensures that the Car Battery Charger Plastic Shell/Enclosure we produce exhibits consistently high quality, performance, and reliability, suitable for various charger applications.