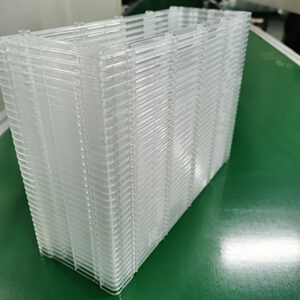

One-Stop Solution for Plastic Hydrogen Fuel Cells Battery Cover

Our one-stop service is designed to help customers meet their battery enclosure needs, providing comprehensive support from product design to production and delivery.

- Professional Design Support

- Material Selection and Recommendations

- Custom Manufacturing

- Color and Appearance Options

- Stringent Quality Control

- Timely Delivery

- Sustainability Practices

Techniques

- Injection Molding: Injection molding is a common method for producing plastic battery covers. It involves injecting heated plastic material into molds and then cooling and solidifying it to achieve the desired shape.

- Mold Design and Fabrication: Custom molds need to be designed and fabricated to ensure precise dimensions and shapes of the battery covers. Mold design considers factors such as material flow, cooling, and venting.

- Multi-Material Injection Molding: Some battery covers require a combination of different materials, such as an external protective layer and an internal structural layer. Multi-material injection molding technology can precisely inject different materials into the mold to achieve the desired structure and performance.

- Post-Processing Techniques: Post-processing techniques may include removing mold markings, surface polishing, painting, or applying printed labels to enhance appearance and functionality.

- Assembly and Sealing: In certain applications, battery covers may need to be assembled with other components, such as gaskets or electronic elements. This requires specialized assembly techniques to ensure sealing and functionality.

- Quality Control: Quality control processes involve dimension measurements, visual inspections, and performance testing to ensure that each battery cover meets quality standards.

Materials:

- Polycarbonate (PC)

- Polypropylene (PP)

- Polystyrene (PS)

- Polyvinyl Chloride (PVC)

- Nylon (PA)

- Polystyrene (PS)

- Polyether Ether Ketone (PEEK)

- Other Engineering Plastics

Common Options for Surface Treatments on Plastic Battery Covers:

- Painting

- Silk Screening

- Plating

- Polishing

- Printing

- Surface Texture

- Anodizing

- Stickers or Covers

Different surface treatment methods can be chosen based on the purpose and requirements of the battery cover, fulfilling needs for appearance, protection, functionality, and brand identification. Selecting the appropriate surface treatment contributes to customizing battery covers to meet the specific requirements of an application.