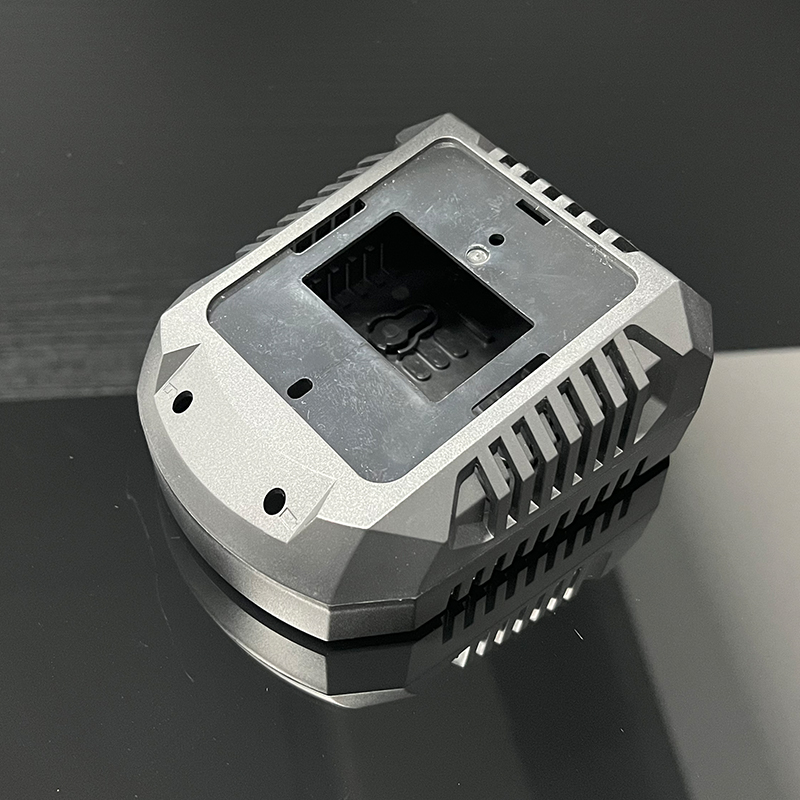

Custom Battery Case Mould OEM Battery Box Mold Factory

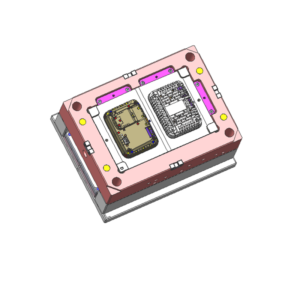

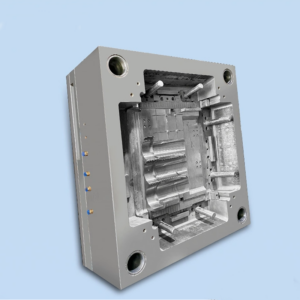

Discover our expertise in designing custom battery box molds at our state-of-the-art factory. Utilizing a standard mold base and HI3 steel with Copper Beryllium inserts for efficient heat transfer, our meticulous process ensures precision. The 7-tip YUDO hot runner system guarantees uniform wall thickness, while hand-polishing each insert prevents demolding scratches. With an efficient cooling system, our molds achieve a remarkable 55-second cycle time per shot. Independent cooling systems for each cavity maintain size consistency.

Our battery box molds offer a unique feature – the ability to interchange side ledges without removing the mold from the injection machine. This innovative technology not only saves costs but also significantly reduces production time. Trust our extensive experience in continuous mold testing to ensure optimal performance in your factory. Experience the future of battery case molding with our cutting-edge solutions.

Mold Production Process

- Blueprint Confirmation: Once the mold design is approved, the production process commences. This involves meticulous steps such as steel preparation, CNC rough machining, deep hole drilling, EDM, drilling machine operations, high-speed milling, and finishing.

- Quality Materials: Our company exclusively utilizes high-quality mold steels known for their extended service life. This ensures the durability and longevity of the molds.

- Precision Machining: Advanced equipment is employed to achieve a remarkable tolerance of +/- 0.01mm. Our molds undergo a high precision machining process to meet the most stringent standards.

- Aesthetic Excellence: The appearance of our die products is flawless, devoid of any flash, and seamlessly complements other products in the market.

- Efficient Cooling System: We have implemented an efficient equilibrium cooling system, enhancing the overall performance and lifespan of the molds.

- Selective Steel Usage: Careful consideration is given to the selection of steel for each component of the mold, ensuring optimal functionality and structural integrity.

- Innovative Hot Runner Technology: Our molds feature cutting-edge hot runner technology with valve gates, significantly improving mold efficiency and ensuring precise control over the molding process.

Our commitment to excellence is evident throughout the entire production cycle, resulting in top-tier battery case molds that meet both professional standards and user expectations.